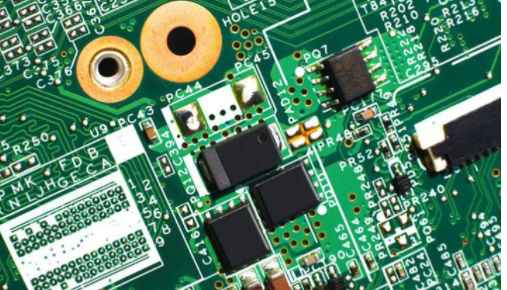

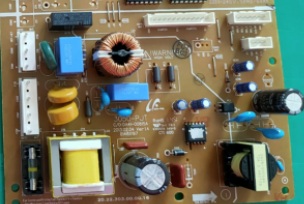

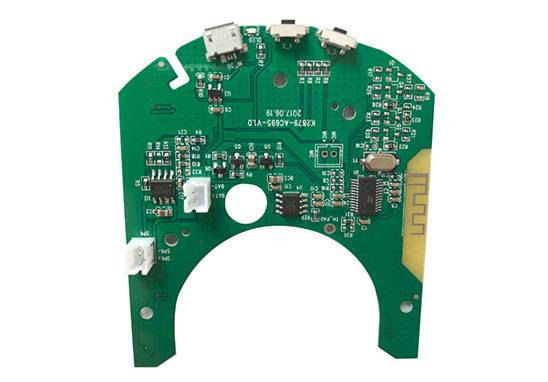

This paper summarizes the packaging problems prone to occur in SMT patch processing

Reflow welding may have some effects on SMT machining quality: 1. PCB deformation caused by temperature gradient; 2. Component damage caused by temperature gradient, 3. Oxidation in reflow welding process