High current thick copper board PCB design

High current thick copper board PCB design

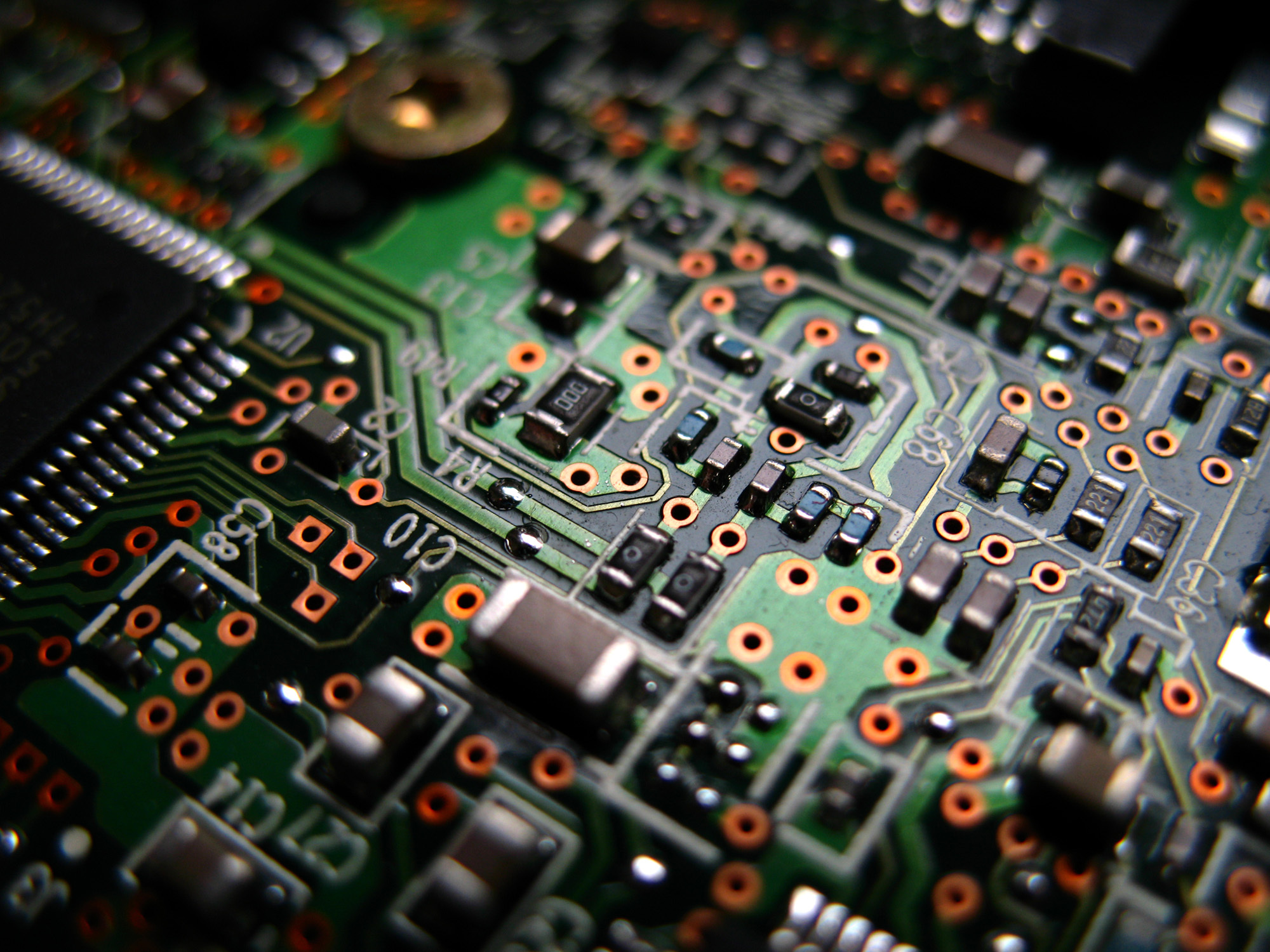

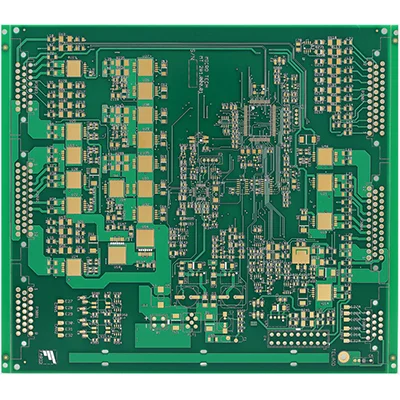

Thick copper PCB is a circuit board with copper thickness ≥3oz/sq. Ft on its exterior and interior. What makes a board classified as a thick copper PCB is its thicker plating. When producing thick copper PCBs, the copper thickness is enhanced by plated holes and sidewalls.

For example, a PCB has 2 ounces of copper per square foot. feet thick and is a standard PCB. However, if it has more than 3 ounces of copper, it's a thick copper PCB. Thick copper PCBs are considered a reliable routing option. Thick copper PCBs differ from extreme copper PCBs, which are characterized by 20 ounces to 200 ounces per square foot.

The extra copper thickness allows the board to conduct more current. Thick copper PCB has strong mechanical power in plated through holes and joints. This type of PCB is also known as thick copper PCB.

What does thick copper PCB offer?

Thick copper PCBs have a lot to offer. It has some unique features that make it ideal for high-end applications. Let's discuss some of the benefits of this type of PCB;

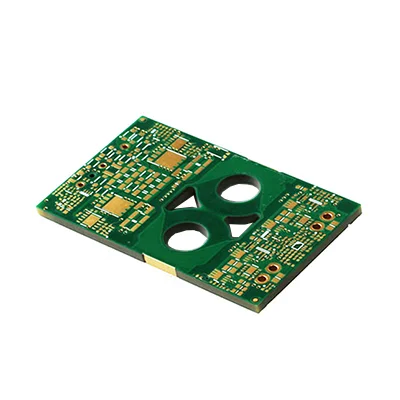

Great Thermal Distribution: Due to its copper-plated through-holes, this PCB offers high thermal resistance. Thick copper PCBs are used for applications requiring high speed and high frequency. You can also use this PCB in harsh temperatures.

Mechanical Strength: Thick copper PCB has high mechanical strength. When this PCB is used, it makes the electrical system durable and strong.

Good Conductor: Thick copper circuit boards are good conductors. Due to this property, they are used in the production of electronics. They help to connect the various boards together. These plates can pass current.

Onboard Heatsink: Thick copper plate provides onboard heatsink. Using these plates you can achieve effective heat sinks on mosaic surfaces.

Huge Dissipation Factor: Thick copper PCBs are ideal for large assemblies with high power dissipation. These PCBs protect electrical systems from overheating. They dissipate heat efficiently.

Supports exotic materials: Thick copper helps protect and enhance exotic materials. Exotic materials are sometimes used to design electronic components. Extreme temperatures may call for an exotic material. Heavy copper plates end circuit failures as they use an exotic material to fully function.

What are the steps of thick copper PCB proofing?

For the fabrication of thick copper PCBs, electroplating or etching is usually used. The main purpose is to increase the copper thickness of the sidewalls and plated holes. Methods for fabricating thick copper PCBs are not out of reach. Thick copper pcbs require special etching and plating methods to ensure the extra thickness of copper.

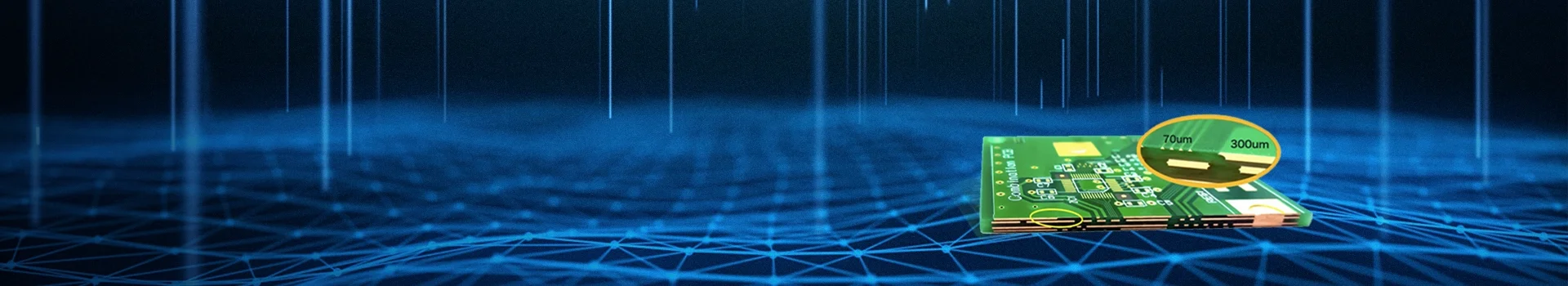

It is not ideal to use common etch technology to make thick copper PCB. Normal etching methods will produce over-etched edges and uneven edge lines. PCB producers now use advanced etching and plating methods to achieve straight edges.

During thePCB manufacturing process, thick copper PCBs are plated. This will help thicken the PTH wall on the PCB. Using this technique, the number of layers is reduced and the impedance distribution is reduced. Plated holes can become weak when the PCB is exposed to several cycles during fabrication.

The fabrication of thick copper pcbs has its limitations, including;

Etching process adds cost

The etch process needs to remove a lot of copper

Difficult to make thinner lines and thicker copper wires

What is thick copper plate?

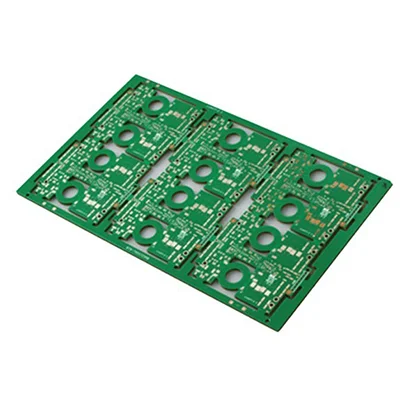

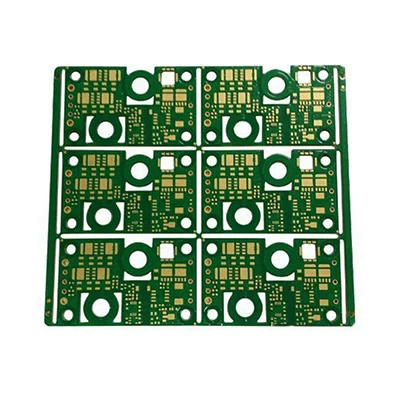

Thick copper boards are PCB boards with thicker wiring layers. Some factories will distinguish PCB boards with a wiring layer copper thickness ≥ 2oz from ordinary boards and call them thick copper boards.

Why do high currents require thick copper plates?

First of all, the thick copper plate has a strong current carrying capacity.

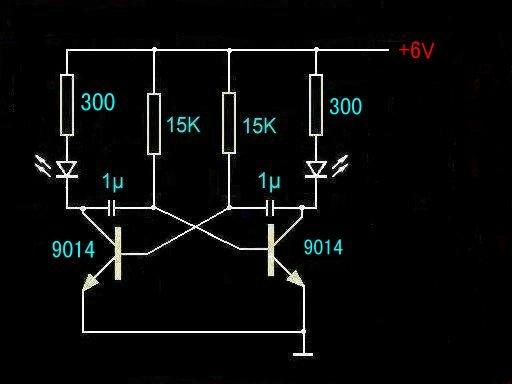

According to the formula:

High extension thick copper calculation formula

(Wherein, I represents the loadable current, U represents the voltage, R represents the resistance, S represents the cross-sectional area of the line, ρ represents the resistivity, L represents the length of the line, w represents the width of the line, h represents the thickness of the line)

It can be seen that when other conditions remain unchanged (especially the line width), the loadable current I of the line is proportional to the thickness h of the line, and the thicker the line, the greater the loadable current.

Secondly, the thick copper plate has good heat dissipation.

We all know metal substrates, the typical representatives of which are aluminum substrates and copper substrates, which have excellent heat dissipation performance. The thick copper plate, because the copper thickness is relatively thick, can also have a certain heat dissipation performance.

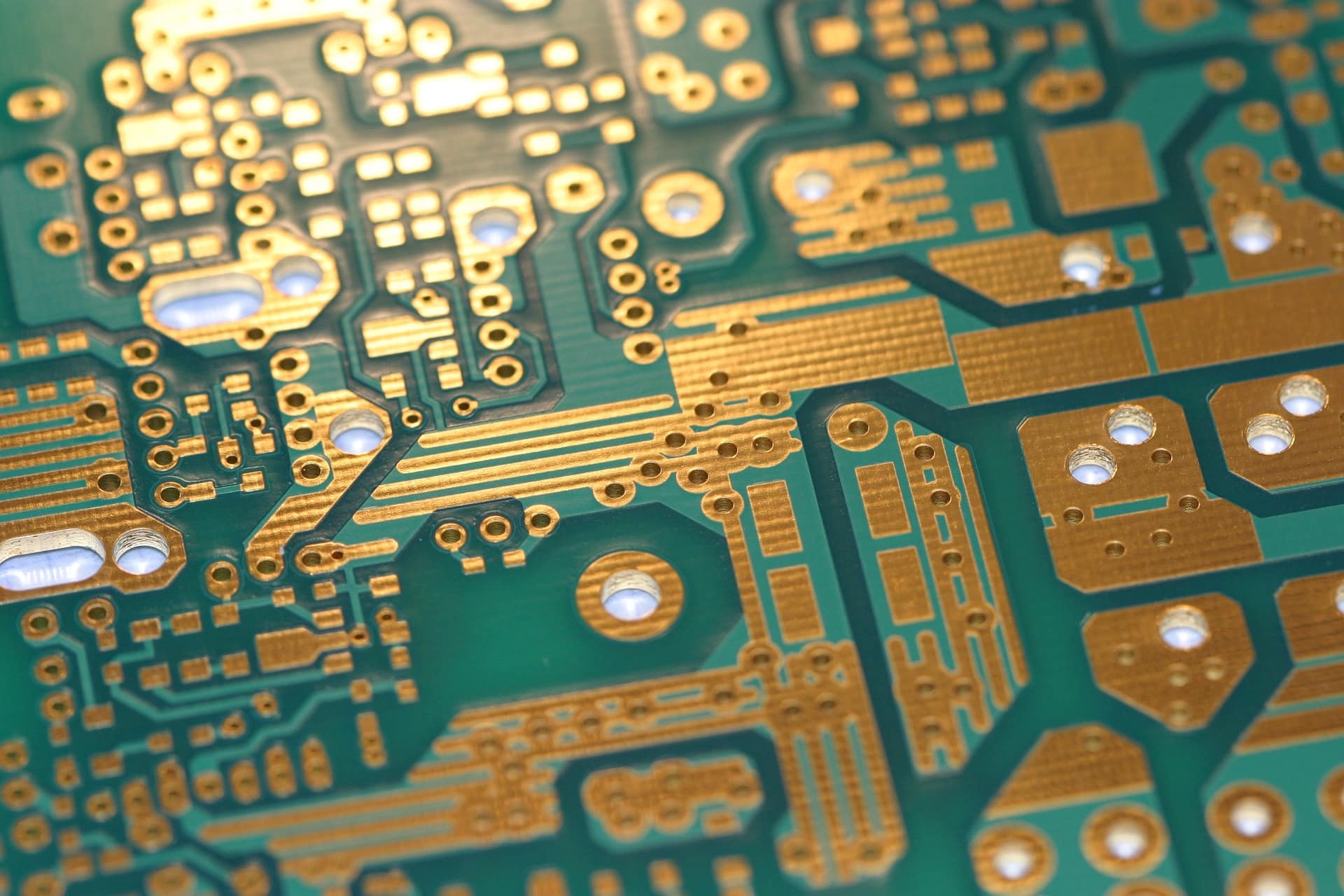

The following is a set of related experiments on the influence of copper foil thickness on heat dissipation:

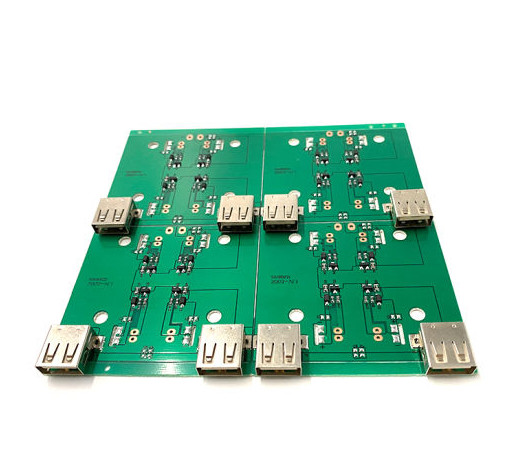

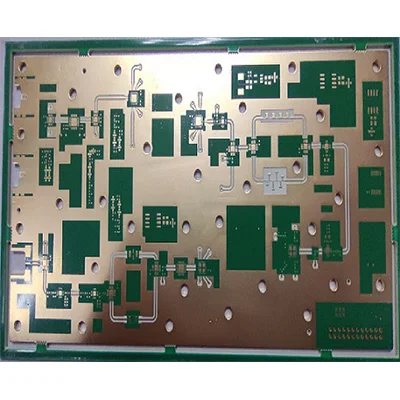

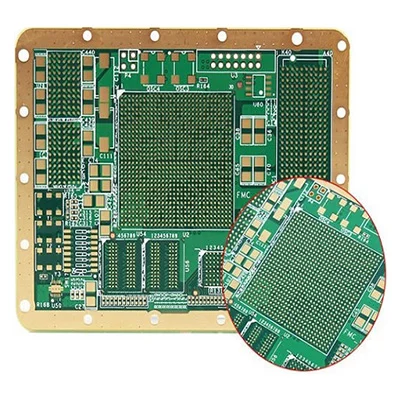

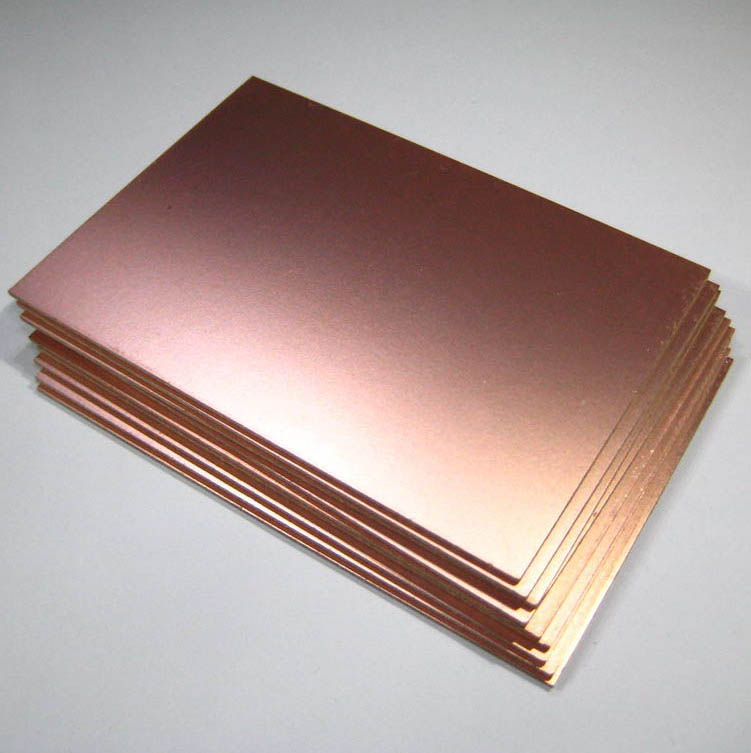

Circuit board thick copper plate

Using the single variable method, gradually increase the thickness of the copper foil, and measure the temperature difference between the two ends of the copper foil.

According to the change curve, it can be seen that with the gradual increase of the thickness of the copper foil, the temperature difference between the two ends of the sample decreases gradually.

Therefore, designing the board as a thick copper board can improve the heat dissipation performance of the board.

Finally, thick copper plates reduce thermal strain.

According to the formula:

(Wherein, Q represents heat generation, I represents passing current, R represents resistance, t represents electrification time, ρ represents resistivity, L represents line length, S represents line cross-sectional area, w represents line width, h represents line thickness )

It can be seen that, when other conditions remain unchanged, the heating value of the circuit is inversely proportional to the thickness of the circuit.

Therefore, designing the board as a thick copper board can reduce heat generation, thereby reducing thermal strain caused by heat generation.

To sum up, unlike ordinary PCBs, thick copper boards have the advantages of carrying large currents, good heat dissipation, and reducing thermal strain, which greatly reduces the risk of board burn-in, and is an excellent option for high-current PCB designs. In addition, designing it as a thick copper plate can also increase the mechanical strength of the circuit board and reduce the volume of the end product.

With the development of science and technology, people need more and more electronic products with high performance, multiple functions, small size, high current carrying capacity and good heat dissipation. Therefore, the demand for thick copper plates is also increasing. For this reason, Gaotuo Electronics PCB added 3oz/4oz thick copper board (inner/outer layer) on the original basis.

- Previous:Copper substrate

- Next:No