Causes of SMD component displacement and targeted solutions

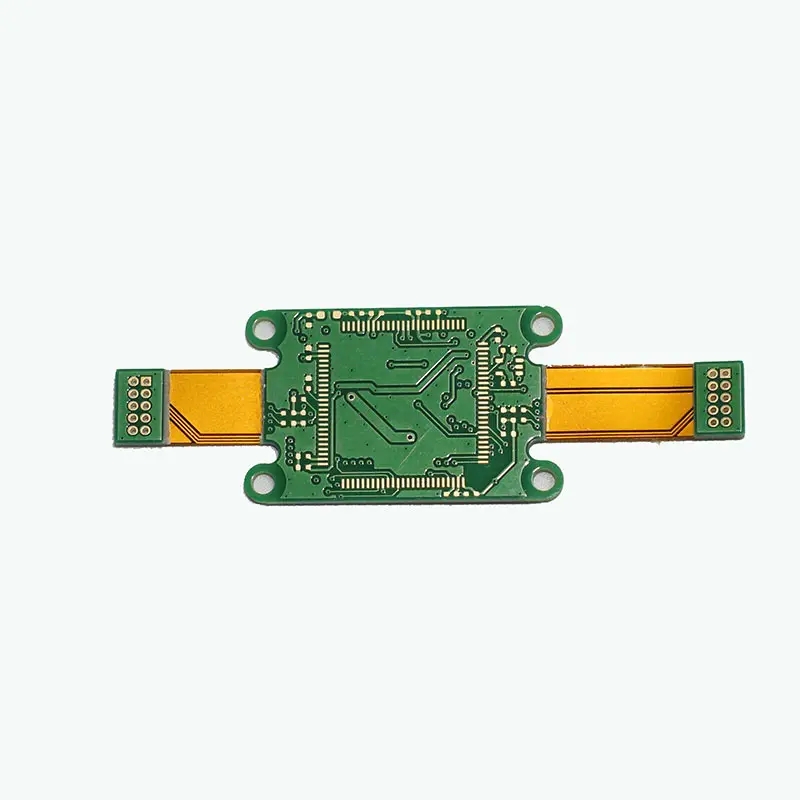

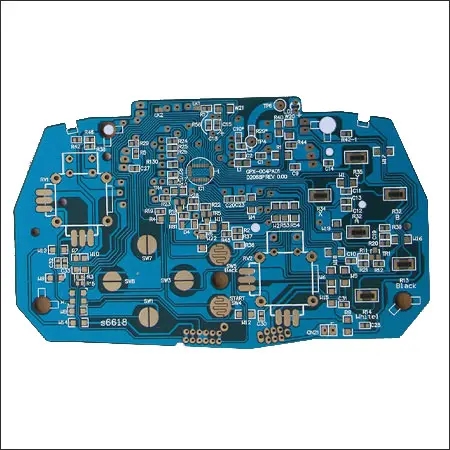

SMT chip processing is to mount electronic components on PCB bare board and realize welding through successive processes.

First, print the solder paste of the welding material on the bonding pad of the bare PCB

Then, use the placement machine to mount the electronic components onto the bonding pads of the PCB bare board (these pads have solder paste, which has a certain viscosity, and can stick to the electronic components)

Next, send PCB board to reflow soldering for soldering

Finally, use AOI detector to check the welded PCB to ensure that there are no welding defects. This process is called SMT chip processing

The main purpose of SMT chip processing is to accurately install the surface mounted components to the fixed position of PCB. However, some process problems sometimes occur during the chip processing, which affect the quality of the chip, such as the displacement of the components, solder bonding, solder leakage and other process problems during the smt chip processing. We should pay attention to the problems caused by any country of origin.

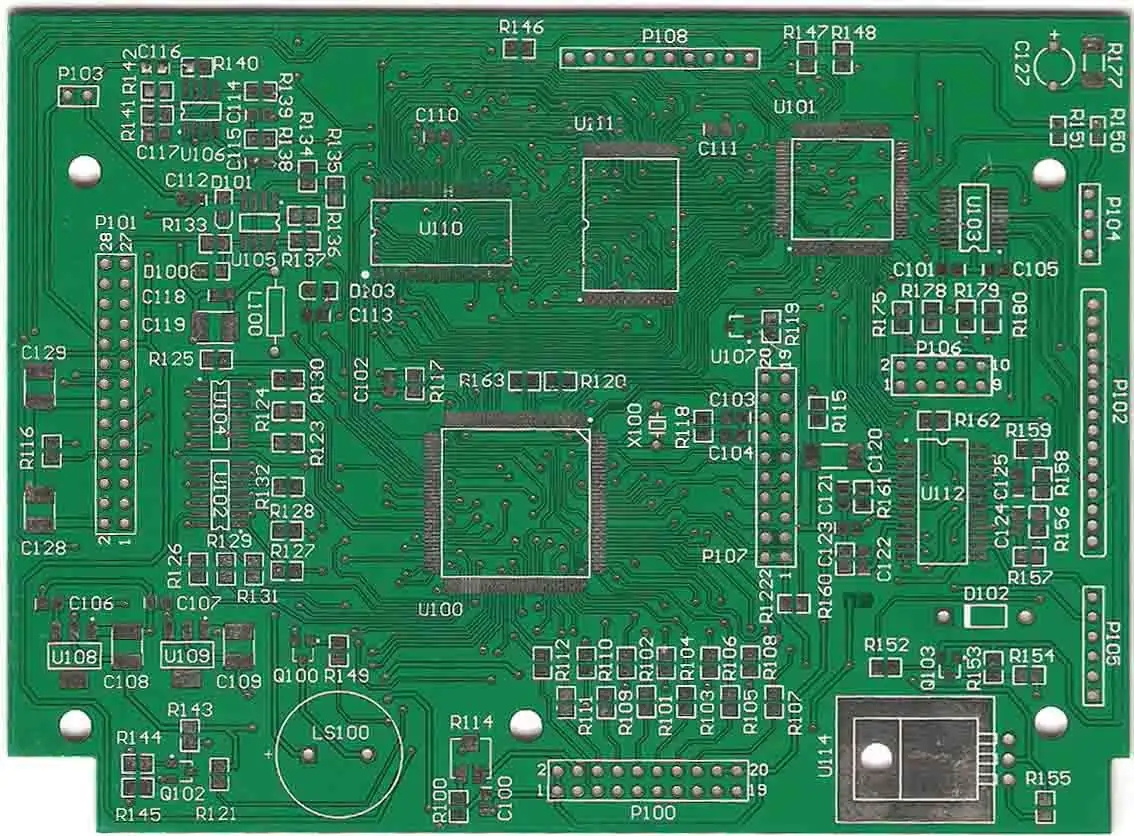

For the reasons for the displacement of SMD components, the reasons can be found from the following aspects: the reasons for the displacement of components in SMD processing:

1. The use time of solder paste is limited. After the use life is exceeded, the flux in the solder paste will deteriorate and the soldering will be poor.

2. The solder paste itself is not sticky enough, and the components vibrate and shake during handling, which causes the components to shift.

3. The flux content in the solder paste is too high, and excessive flux flow during reflow leads to the displacement of components.

4. During the handling of components after printing and mounting, the components are displaced due to vibration or incorrect handling methods.

5. During patch processing, the air pressure of the suction nozzle is not adjusted properly, and the pressure is not enough, causing the displacement of components.

6. The placement position of components is incorrect due to the mechanical problems of the mounter itself.

Once components shift during smt chip processing, it will affect the use performance of the circuit board. Therefore, it is necessary to understand the causes of components shift during the processing and solve them accordingly.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the reasons for the placement of SMD components and their targeted solutions.