From the point of view of welding PCB design should pay attention to the problems

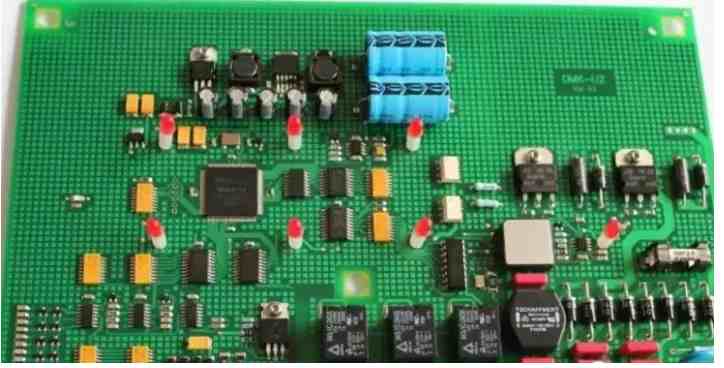

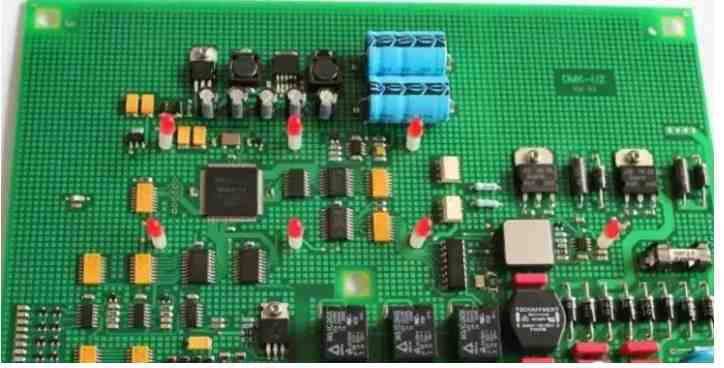

From PCB design to the completion of all components welding into a high quality circuit board, PCB design engineers and even the level of welding process, welding workers and many other links have strict control.

There are mainly the following factors: PCB diagram, the quality of the circuit board, the quality of the device, the oxidation degree of the device pin, the quality of the solder paste, the printing quality of the solder paste, the accuracy of the program programming of the placement machine, the mounting quality of the reflow furnace temperature curve setting and so on.

The link that the welding plant itself cannot surmount is the link of PCB design. Because people who do circuit design often do not weld circuit boards, they can not get direct welding experience and do not know the various factors that affect welding. The workers in the welding factory do not understand the drawing board, they only complete the production task, and have no mind and no ability to analyze the causes of poor welding. It is difficult to combine these two talents organically because of their respective roles.

Below, I put forward some suggestions to the design and wiring engineers who draw PCB drawings on the link of PCB design, hoping to avoid various bad drawings that affect the quality of welding in the process of drawing. Will be introduced mainly in the form of graphics.

About the positioning hole

The four corners of the PCB board should be left with four holes (minimum aperture 2.5mm) for positioning the circuit board when printing solder paste. The center of the X-axis or Y-axis direction is required to be on the same axis, as shown below:

For placement machine positioning. The PCB board should be marked with the Mark point, the specific position: on the diagonal of the board, it can be a round or square pad, and do not mix with the pad of other devices. If there are devices on both sides, both sides should be marked.

When designing PCB, please pay attention to the following points:

a. Mark points are shaped like the following pattern. (top and bottom symmetry or left and right symmetry)

From the point of view of welding PCB design should pay attention to the problems

b. The dimensions of b and A are 2.0mm.

c. From the outer edge of the Mark point within the range of 2.0mm, there should be no shape and color changes that may cause misidentification. (Pad, solder paste)

d. The color of the Mark point should be different from the color of the surrounding PCB.

e. In order to ensure the identification accuracy, the surface of the Mark point is plated with copper or tin to prevent surface reflection. Marks for shapes are only lines, points of light cannot be recognized.

When drawing the PCB, leave no less than 3mm of the edge in the long side direction for the placement machine to transport the circuit board, and the placement machine cannot mount the device in this range. Do not place the patch device within this range.

The circuit board with devices on both sides should take into account that the second over-reflux will rub off the device on the side of the soldered side, and the welding pad will be rubbed off and the circuit board will be destroyed. As shown in the picture below:

Therefore, it is recommended that the long side of the less side of the chip (generally the Bottom surface) should not be placed within 5mm from the side. If it is true that the area of the circuit board is limited, the process edge can be added on the long side, see the 17 "Suggestions on the board and the process edge" in this article.

Do not directly hole the pad

The defect that passes directly through the hole on the pad is that the solder paste melts into the hole during overreflux, resulting in the lack of tin on the device pad, and thus forming virtual welding. Figure: Polarity marking of diode and tantalum capacitor

The polarity of diodes and tantalum capacitors should be marked in accordance with industry regulations, so as to avoid workers welding in the wrong direction by experience. As the picture shows:

About screen printing and signage

Please hide the device model. Especially the circuit board with high device density. Otherwise, the dazzle affects finding the welding position. As shown below: Do not only mark the model, do not mark the label. As shown in the following figure, resulting in the placement machine programming can not be carried out.

The IC pad should be extended

SOP, PLCC, QFP and other packaging IC, drawing PCB should pay attention to the width of the pad, the width of the pad a on the PCB = the width of the IC foot (ie: Nom in datasheet). Please do not increase the width to ensure that b(that is, between the two pads) has enough width to avoid continuous welding. As the picture shows:

Do not rotate the device at an arbitrary Angle

Since the mounter cannot rotate at any Angle, it can only rotate 90 ° C, 180 ° C, 270 ° C, 360 ° C. As shown in Figure B below, if the device pin is rotated by 1℃, the Angle between the device pin and the pad on the circuit board will be staggered by 1℃, thus affecting the welding quality. Problems that should be noted when shorting adjacent pins.

The shorting method in Figure a below is not conducive to the worker to identify whether the pin should be connected, and it is not beautiful after welding. If the drawing is shorted and welded according to the method of Figure b and Figure c, the effect of welding is different: as long as each pin is not connected, the chip has no short circuit phenomenon, and the appearance is beautiful.

When drawing a chip with a solder pad in the middle of the chip, it is easy to cause short circuit if the solder pad in the middle of the package picture of the chip is used. It is recommended to reduce the middle pad so that the distance between it and the surrounding pin pad is increased, thereby reducing the chance of short circuit. As shown below:

Do not line up two devices of higher thickness closely together

As shown in the following figure, this will cause the placement machine to touch the previous attached device when mounting the second device, and the machine will detect the danger, resulting in automatic power failure.

Because the BGA package is special, its pad is under the chip, and the welding effect is not visible outside. In order to facilitate the repair, it is recommended to punch two positioning holes with Hole Size:30mil on the PCB board to locate the steel mesh (used to scrape the solder paste) during the repair. Tips: The size of the positioning hole should not be too large or too small, so that the needle does not fall off after insertion, does not shake, and is slightly tight when inserting, otherwise the positioning is inaccurate. As shown below:

Moreover, it is recommended to leave open space to place the device within a certain range around the BGA, so that the mesh board scraping paste can be placed during repair.

Don't make it red. Because the red circuit board is white under the red light source of the camera of the chip machine, it cannot be programmed and is not easy for the chip machine to weld.

About the small device underneath the big device

Some people like to line up small devices under the same layer of large devices, such as: there is a resistor under the digital tube, as shown below:

This layout will cause difficulties to repair, repair must first remove the digital tube, and may cause damage to the digital tube. It is recommended to drain the resistance under the nixie tube to the Bottom surface, as shown below:

The connection between the copper coating and the pad affects the solder melting

Because the copper coating will absorb a lot of heat, it is difficult to fully melt the solder, resulting in the formation of virtual welding. As shown in the picture:

In Figure a, the device pad is directly connected with the copper coating; Although the 50Pins connector in Figure b is not directly connected with the copper coating, since the middle two layers of the four-layer plate are large-area copper coating, the solder paste in Figure a and Figure b cannot be fully melted because the copper coating absorbs a lot of heat. The body of 50Pins connector in Figure b is a plastic that is not resistant to high temperature. If the temperature is set high, the connector will melt or deform. If the temperature is set low, the copper coating will absorb a lot of heat, resulting in the solder paste cannot be fully melted. Therefore, it is recommended that the pad be isolated from large area copper coating. As shown in the picture:

Nowadays, more and more engineers can draw, wire and design PCB with software, but once the design is completed, and can improve the welding efficiency, the author believes that it is necessary to pay attention to the above elements. And cultivate a good habit of drawing, and be able to communicate well with the processing plant, which is what every engineer should consider.

Shenzhen Kingford Technology Co., Ltd. is a professional engaged in electronic products circuit board design (layout layout design) PCB design company, mainly undertake multi-layer, high-density PCB design drawing board and circuit board design proofing business. With an average of more than 10 years of work experience in PCB design team, can skillfully use the market mainstream PCB design software, professional and efficient communication to ensure PCB design progress, to help you seize the market opportunity one step earlier.