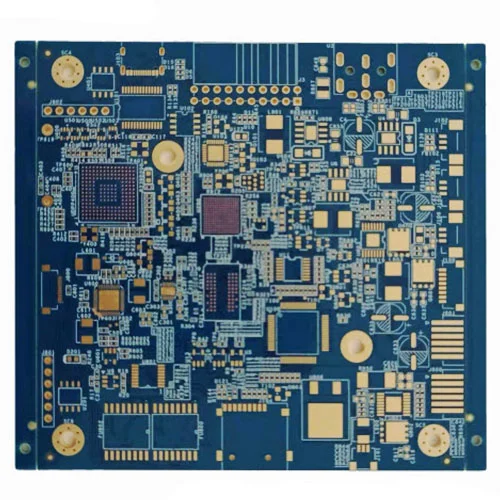

Name: Car driving recorder HDI PCB

Tier: 1+6+1

Sheet: EM825

Plate thickness: 1.6mm

Size: 242mm*165mm

Minimum blind hole: 0.1mm

Min Buried Via: 0.25mm

Minimum line width: 0.088mm

Minimum line spacing: 0.087mm

Surface Treatment: Immersion Gold

Outline tolerance: +/-0.1mm

Special requirements: L3-L6 resin plug holes

10-layer 1-stage HDI communication PCB

Name: 10-layer 1-stage HDI communication PCB

Layers: 1+8+1

Sheet: FR4 Tg170

Plate thickness: 1.2mm

Panel size: 110.8*94.8mm/4

Outer copper thickness: 35μm

Inner layer copper thickness: 18μm

Minimum through hole: 0.20mm

Minimum blind hole: 0.10mm

Minimum BGA: 0.20mm

Line width and line spacing: 2.5/2.2mil

Surface Treatment: Immersion Gold 2μ''+OSP

Application field: communication

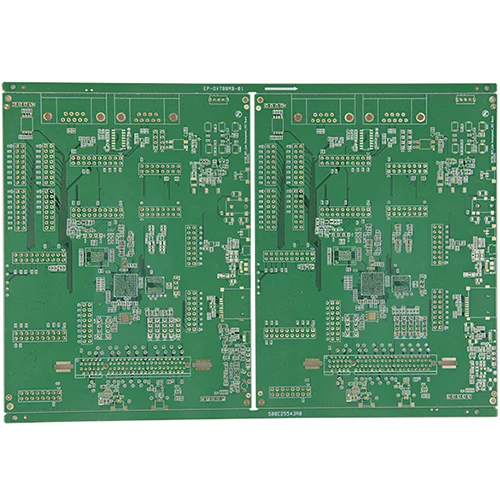

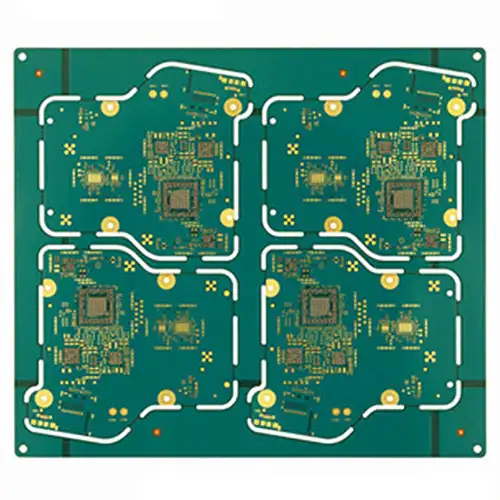

6L 2+N+2 HDI Communication PCB

Name: 6L 2+N+2 HDI Communication PCB

Model : 2+N+2 HDI Communication PCB

Layers : 6Layers

Material: IT150

Construction : 2+2+2 HDI PCB

Finished Thickness: 0.8mm

Copper Thickness: 0.5OZ

Color : Green/White

Surface Treatment: Immersion Gold+OSP

Min Trace / Space: 3mil/3mil

Min Hole: Laser Hole 0.1mm

Application : Communication HDI PCB

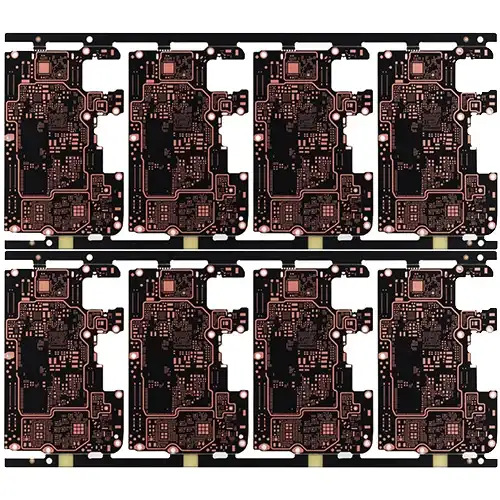

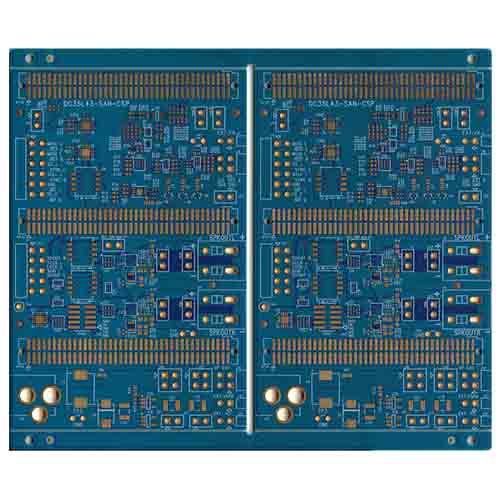

Name: 6L 2+N+2 HDI WiFi Module PCB

Layers : 6Layers

Material:FR4 Tg170

Construction : 2+2+2 HDI PCB

Finished Thickness: 0.8mm

Copper Thickness: 1OZ

Color : Black/White

Surface Treatment: Immersion Gold+OSP

Min Trace / Space: 3mil/3mil

Min Hole: Laser Hole 0.1mm

Application : WiFi module PCB

Name: 6-layer 1-stage HDI PCB

Layers: 1+4+1

Sheet: FR4 Tg150

Plate thickness: 1.6mm

Panel size 105*95mm/1

Outer copper thickness: 35μm

Inner layer copper thickness: 30μm

Minimum through hole: 0.20mm

Minimum blind hole: 0.10mm

Minimum BGA: 0.20mm

Line width line spacing: 3/3mil

Surface Treatment: Immersion Gold 2μ''+OSP

Application field: industrial control

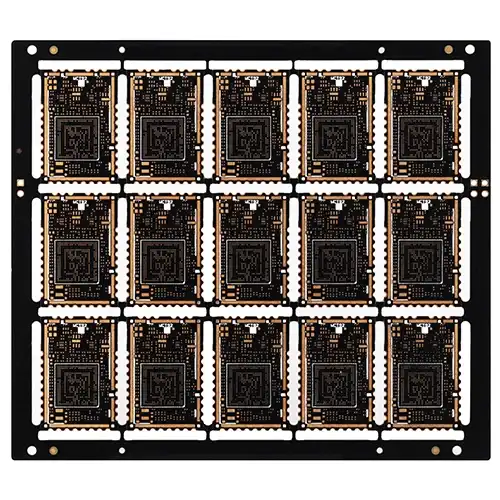

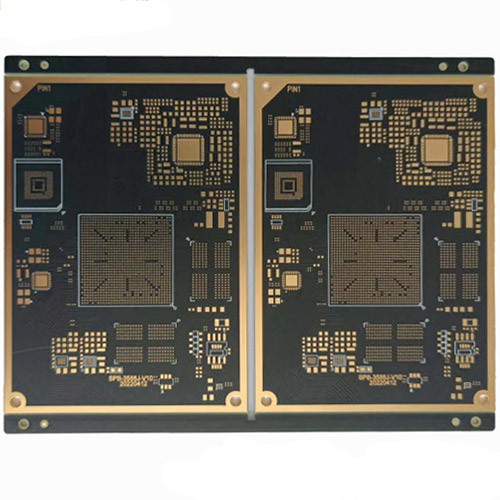

Name: 10-layer 3-stage HDI PCB

Layers: 3+4+3

Sheet: FR4 Tg170

Plate thickness: 1.2mm

Panel size: 126*118mm/4

Outer copper thickness: 35μm

Inner layer copper thickness: 18μm

Minimum through hole: 0.20mm

Minimum blind hole: 0.10mm

Minimum BGA: 0.25mm

Line width and spacing: 2.8/3.2mil

Surface Treatment: Immersion Gold 2μ''+OSP

Name: 10-layer 1-level HDI pcb

Layers: 1+8+1

Sheet: FR4 Tg170

Plate thickness: 1.6mm

Panel size: 121.6*95mm/2

Outer copper thickness: 1OZ

Inner layer copper thickness: 1OZ

Minimum through hole: 0.20mm

Minimum blind hole: 0.10mm

Minimum BGA: 0.25mm

Line width line spacing: 3/2.7mil

Surface Treatment: Immersion Gold 2μ''

Blind hole process: hole filling and electroplating

Name: 2+N+2 HDI ITEQ PCB 6L PCB

Model : 6L 2+N+2 HDI PCB

Material: ITEQ IT150

Layer: 6L 2+N+2 HDI

Color: Black/White

Finished Thickness: 1.0m

Copper Thickness: inner1OZ outer0.5OZ

Surface Treatment :Immersion Gold +OSP

Min Trace / Space: 2.5mil/2.5mil

Min Hole: Mechanical hole 0.2mm, Laser Hole 0.1mm

Application: Communication pcb

Communication equipment 2-stage HDI PCB board

Name: Automotive communication second-order HDI board

Plate: S1000-2M

Layers: 14L

Material: ISOLA

Plate thickness: 1.6±0.16mm

Minimum aperture laser hole: 0.10mm

Mechanical hole: 0.20mm

Minimum track/spacing: 75/75um

Minimum plate thickness and porosity: 8:1

Special process: 2 laser drilling, 3 pressing, second-order HDI board

Use: vehicle communication

Twelve-layer second-order board

name: Twelve-layer second-order board

Plate: FR4

Layers: 12L

Material: ISOLA

Plate Thickness: 2.0mm

Copper thickness of inner and outer layers: 1oz

Minimum hole diameter: 0.1mm

Surface Treatment: Immersion Gold

Line width: 0.1mm

Line distance: 0.1mm

BGA pad: 0.15mm

Special craftsmanship: second stage

Use: consumer electronics

- PCB Manufacturing Equipment

- HDI PCB Capability

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine

| HDI (High Density Interconnect) PCB Process Capability | ||

| Item | batch | Template |

| layers | 4-16 Layers | 4-24 Layers |

| Plate thickness range | 0.6-3.2mm | 0.4-6.0mm |

| highest order | 4+N+4 | Any layer innterconnected |

| Minimum laser hole | 4mil (0.1mm) | 3mil (0.075mm) |

| Laser process | CO2 Laser Machine | CO2 Laser Machine |

| Tg value | 140/150/170°C | 140/150/170°C |

| hole copper | 12-18μm | 12-18μm |

| Impedance tolerance | +/-10% | +/-7% |

| interlayer alignment | +/-3mil | +/-2mil |

| Solder Mask Alignment | +/-2mil | +/-1mil |

| Minimum line width/line spacing | 2.5/2.5mil | 2.0/2.0mil |

| Smallest grommet | 2.5mil | 2.5mil |

| Minimum through hole | 8mil (0.2mm) | 6mil(0.15mm) |

| smallest micropore | 4.0mil | 3.0mil |

| Minimum media thickness | 3.0mil | 2.0mil |

| Minimum pad | 12mil | 10mil |

| Micropore Aperture Aspect Ratio | 1:1 | 1:2:1 |

We have robust quality inspection procedures, and most importantly, a large number of satisfied customers is the greatest testimony to our success.

Yes, we provide high-density PCB manufacturing services, if you have any needs, please contact sales@kingfordpcb.com