With the rapid development of high-tech industries such as mobile phones, electronics, communications, and autonomous driving, the PCB circuit board industry has largely driven the continuous expansion and rapid growtothe circuit board industry, and people's requirements for the quality of the circuit board, thenumberlayeweight,precision, materials, color, and reliability are also getting higher and higher.

Also due to the fierce market price competition, the cost of PCB circuit board materials is also in the rising trend, more and more manufacturers in order to enhance the core competitiveness of the industry, choose to try to monopolize the market at low prices. However, behind these ultra-low prices, often obtained by reducing material costs and process costs, which leads to the quality of the circuit board itself is not up to scratch, so the circuit board is usually prone to cracks (cracks), easy to scratch, (or abrasion), its precision, performance and other comprehensive factors are not up to standard, seriously affecting the reliability of the circuit board. Should prove that cheap no good goods, but good goods must not be cheap is an ironproof fact, in the face of a variety of circuit board manufacturers on the market, how to distinguish from the appearance of the circuit board is good or bad, the next professional circuit board manufacturer - Shenzhen Hongli Jie Electronics for you to introduce.

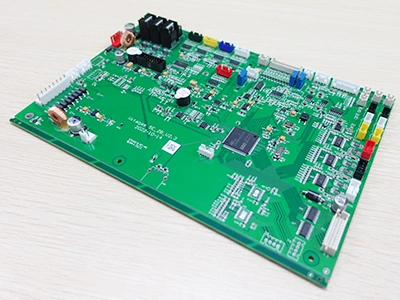

Under normal circumstances, the circuit board can be judged by several aspects of appearance analysis; 1. Light and color. The external PCB circuit board is covered with ink, the circuit board can play the role of insulation, if the color of the board is not bright, less ink, the insulation board itself is not good. 2, PCB circuit board size and thickness of the standard rules. The thickness of the circuit board to the standard circuit board is different sizes, customers can measure and check according to their own product thickness and specifications. 3, PCB circuit board weld appearance.

Because there are more parts of the circuit board, if the welding is not good, the parts are easy to fall off the circuit board, which seriously affects the welding quality of the circuit board, the appearance is good, carefully identify, and the interface is very important. Energy production from 2 layers to 14 layers, 14-22 layers can be proofing production. Minimum line width/spacing: 3mil/3milBGA Distance :0.20MM Minimum aperture: 0.1mm Size :610mmX1200mm Ink: Tamura, Taiyo, Fudoken; FR4: Sheng Yi, Kingboard, Harbour, Hongren, Guoji, Hezheng, South Asia,

(Shengyi S1130/S1141/S1170),Tg130℃/ Tg170℃ T g180℃ and other high TG plates)

High frequency board: Rogers, Taconic, ARLLON; Surface process: spray tin, lead-free spray tin, sinking gold, full plate gold plating, plug gold plating, full plate thick gold, chemical sinking tin (silver), anti-oxidation (OSP) blue glue, carbon oil.

1.Strength guarantee

SMT workshop: with imported SMT machines, optical inspection equipment, can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

DIP production line: there are two wave soldering, of which there are more than 10 old employees who have worked for more than three years. The workers have high proficiency and can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

High-end equipment can be attached to precision shaped parts, BGA, QFN, 0201 materials. Also can be template patch, loose material hand.

Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

Accumulated services for thousands of electronic enterprises, involving many types of automotive equipment and industrial control motherboard SMT processing services, products are often exported to Europe and the United States, quality can be affirmed by new and old customers.

Punctual delivery, normal 3-5 days after complete materials, small batches can also be expedited on the same day

4. Strong maintenance ability, perfect after-sales service

Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connectivity of each PCB circuit board.

24-hour customer service staff responds at any time to solve your order problems as quickly as possible.