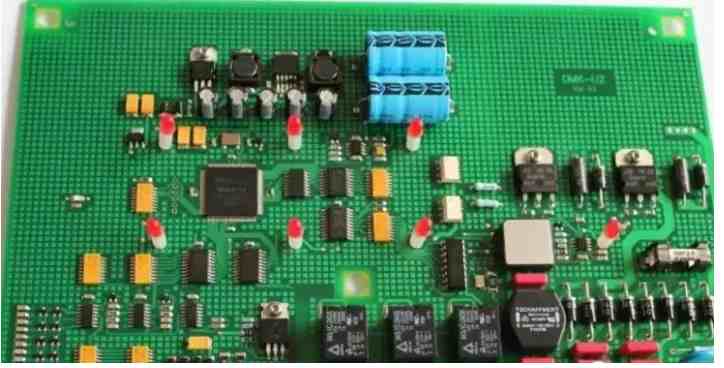

How to protect multi-layer PCB edge radiation through PCB design?

Often see a lot of industrial board or RF board in the PCB board around will play a circle of holes and copper tape, and even some RF board will be metallized in the edge of the board, what is the routine to do this? Is that the siege lion wearing 13The edge radiation of multilayer PCB is a common source of electromagnetic radiation

Nowadays, with the increase of system speed, not only the timing and signal integrity problems of high-speed digital signals are prominent, but also the EMC problems caused by electromagnetic interference and power integrity generated by high-speed digital signals in the system are also prominent. The electromagnetic interference generated by high-speed digital signals will not only cause serious interference inside the system, reduce the anti-interference ability of the system, but also produce strong electromagnetic radiation to the outer space, causing the electromagnetic radiation emission of the system to seriously exceed the EMC standard, so that the product can not pass the EMC standard certification. The edge radiation of multilayer PCB is a common source of electromagnetic radiation.

Edge radiation occurs when an unexpected current reaches the edge of the ground layer and the power layer. These unexpected currents may result from ground and supply noise caused by inadequate power bypass. - A cylindrical radiating magnetic field generated by the inductive hole, which radiates between the layers of the board and eventually meets at the edge of the board. - The strip return current carrying the high frequency signal is too close to the edge of the board.

Source of power supply noise

The source of the power supply noise mainly lies in two aspects: first, the transient alternating current is too large in the high-speed switching state of the device; The second is the inductance existing in the current circuit. From the perspective of expression, it can be divided into three categories:

Synchronous switching noise (SSN), sometimes referred to as ΔI noise, can also be attributed to the phenomenon of Ground bounce;

- Influence of non-ideal power supply impedance;

- Resonance and edge effect.

In high-speed digital circuits, when the digital integrated circuit is powered on, its internal gate output will undergo a state transition from high to low or from low to high, that is, the conversion between "0" and "1". In the process of change, the transistor in the gate circuit will keep on and off, then there will be current from the connected power supply into the gate circuit, or from the gate circuit into the ground plane, so that the power plane or the ground plane of the current imbalance, resulting in an instant change of the current △I. This current creates an AC voltage drop as it flows through the inductors present on the return path, which in turn causes noise. This voltage drop is large enough to cause power integrity problems if a large number of output buffers are simultaneously performing state transitions, and this Noise is known as Simultaneous Switch Noise (SSN).

Power AC noise will be between the power layer and the ground, using the resonator mode of the two planes to conduct AC noise, which will radiate into the free space when transmitted to the edge of the plane, which will lead to the product EMI certification

For the noise generated by the hole, we know that the interconnected signal lines on the PCB include the microstrip line on the outer layer of the pcb and the strip line between the two planes in the inner layer, and the electroplated hole that the signal layer plays a connecting role (the hole is subdivided into through holes, blind holes, and buried holes). The microstrip line in the surface layer and the strip line between the two planes can be well controlled by good reference plane layering structure design.

When the high-frequency signal transmission line passes through the hole to change layers, not only the impedance of the transmission line changes, but also the reference plane of the signal return path changes. When the frequency of the signal is relatively low, the influence of the through hole on the signal transmission can be negligible. However, when the signal frequency rises to the RF or microwave frequency band, the effect of the through hole on the signal transmission can be ignored. Due to the change of the reference plane of the pass hole causing the change of the current return path, the TEM wave generated by the pass hole will propagate laterally between the resonant cavity formed in the two planes, and eventually radiate outward into the free space through the edge of the pcb, resulting in excessive EMI index.

OK, now we know that for high frequency and high speed PCB, edge radiation will occur on the PCB edge, then how to protect it?

The three factors that cause EMC problems are: electromagnetic interference source, coupling path, and sensitive equipment

Sensitive equipment we can not control, cut off the coupling path such as adding a metal shield equipment shell, etc., do not talk about here, and how to find a way to eliminate the source of interference.

First of all, we must optimize the key signal wiring on the PCB to avoid EMI problems, more than the layer change hole, we can punch a ground hole around the key signal hole to provide additional return path for the key signal hole.

Well, for reducing PCB edge radiation, I have heard of a 20H rule before, the 20H rule was first proposed by W.Michael King in 1980, and elaborated by Mark.I.Montrose in his book, and is valued by the business, and is often listed as an important EMI design rule. H refers to the thickness of the board, that is, the distance between the power plane and the ground plane is reduced by 20H.

In order to reduce the effect of edge radiation, the power plane should be smaller than the adjacent plane, and the effect is not obvious when the power plane is reduced for about 10H. When the power plane is shrunk for 20H, 70% of the Flux Boundary is absorbed. When the power plane is shrunk for 100H, 98% of the marginal flux boundary can be absorbed. Therefore, the internal power layer can effectively inhibit the radiation caused by the marginal effect.

The 20H rule is no longer suitable for the current high-frequency high-speed PCB design, the previous printed circuit board area is large, and the resonance frequency of the plane antenna caused by internal shrinkage is less obvious; Nowadays, due to the small surface of the PCB board, the radiation intensity of the design of the internal power layer changes significantly with the resonance point of different internal power layer sizes, resulting in higher radiation energy at high frequencies.

The use of indent 20H can not completely solve the reduction of radiation, although the frequency below 430MHz is improved, and 40H is improved for the frequency below 590MHz, but the resonance frequency is higher due to the reduction of the area, which is not helpful for the radiation suppression of the higher frequency band of resonance frequency.

The future design of EMI, because of the retraction of the power layer 20H will not be helpful, and the smaller the board, the more high-frequency radiation will be more serious due to the change of the plane antenna effect, so the theory of 20H has not met the current actual needs.

Since the 20H rule has become ineffective for the current high-frequency high-speed PCB design, it is necessary to use a shielding structure to process the edge of the pcb board edge radiation, so as to reflect the noise back into the inner space, which will increase the voltage noise on these layers, but the edge radiation is reduced.

Low cost realization method of multi-layer PCB edge radiation protection

The low-cost implementation method is to make a ring of ground holes around the PCB with 1/20 wavelength hole spacing to form a ground hole shield to prevent TME wave radiation.

For the microwave circuit board, its wavelength is further reduced, and due to the PCB production process now, the spacing between holes and holes can not be made very small, at this time has 1/20 wavelength spacing in the PCB around the way to play a shielded hole for the microwave board is not obvious, then you need to use the PCB version of metalization edge process, the entire board edge surrounded by metal, Thus, the microwave signal can not radiate out from the PCB board edge, of course, the use of plate edge metallization process, will also lead to PCB manufacturing costs increase a lot.

For RF microwave boards, some sensitive circuits, and circuits with strong radiation sources can be designed to weld a shielding cavity on the PCB, and the PCB should be added "through the hole shielding wall" in the design, that is, the PCB and the shielding cavity wall close to the part of the ground through the hole. This creates a relatively isolated area. The design requirements of the through hole shielding wall are as follows: - there are more than two rows of through holes; - Two rows of holes staggered from each other;

- The hole spacing in the same row should be less than λ/20;

- Solder resistance is prohibited at the part where grounded PCB copper foil is crimped with the shielding chamber wall.

Shenzhen Kingford Technology Co., Ltd. is a professional engaged in electronic products circuit board design (layout layout design) PCB design company, mainly undertake multi-layer, high-density PCB design drawing board and circuit board design proofing business. With an average of more than 10 years of work experience in PCB design team, can skillfully use the market mainstream PCB design software, professional and efficient communication to ensure PCB design progress, to help you seize the market opportunity one step earlier.