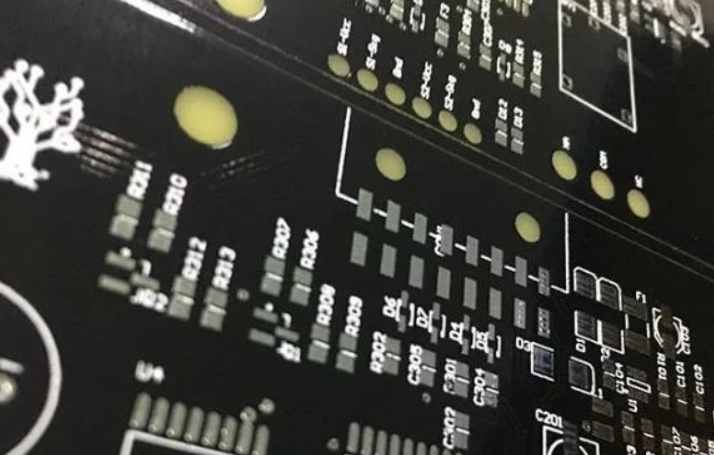

Eight common technical problems of PCB design

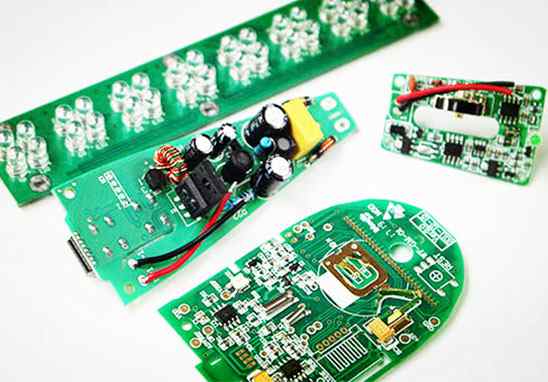

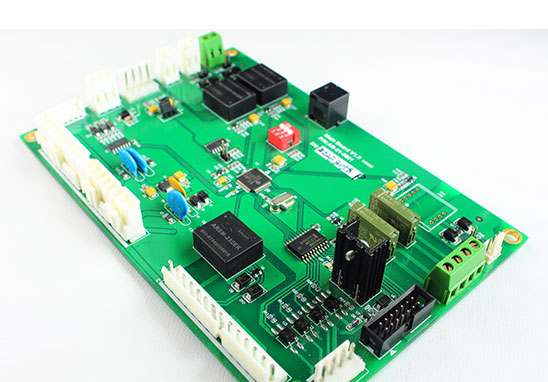

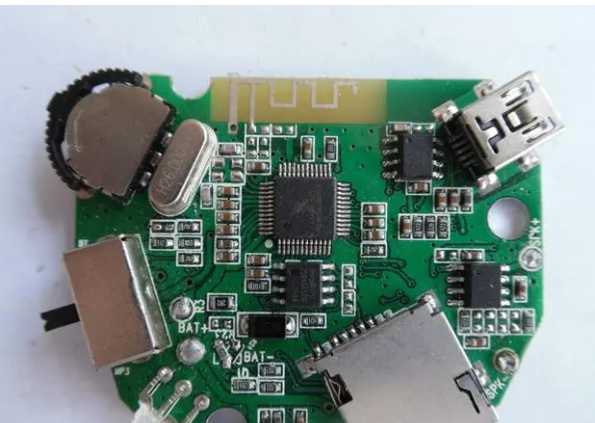

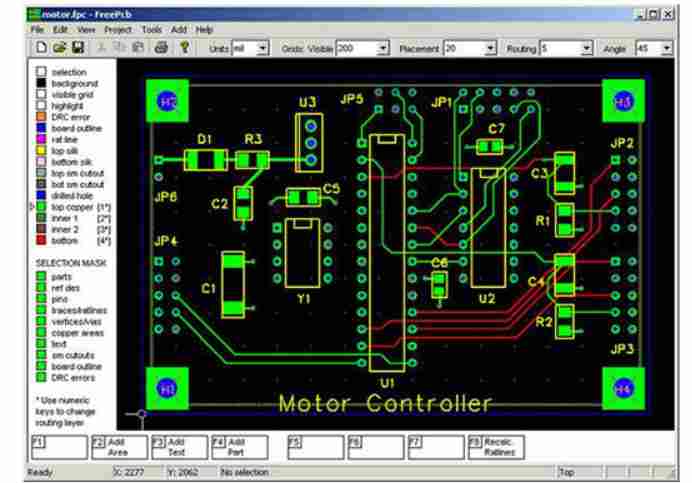

What samples should be provided for PCB circuit board proofing? The quotation information needs to be provided to the manufacturer, and the GEBER file is generally provided for the drawings. There are clear process requirements and quantity. The pcb manuf