Generally, the maintenance and technical elements in the patch processing plant will carry out the following practical operations. You can access the switching power supply and check whether the relative function of the circuit board is normal. After most of all steps are completed, you can distinguish and overhaul the unsatisfactory products of customers according to their BOM, Gerber and circuit schematic diagram. In the patch processing plant, the technical personnel of the maintenance unit are the technical professional players carefully selected in the production workshop. The following patch processing manufacturer to explain what the actual operating standards of PCBA processing and SMT patch processing PCBA maintenance including what aspects of the relevant knowledge.

1. What are the aspects of PCBA maintenance for SMT patch processing

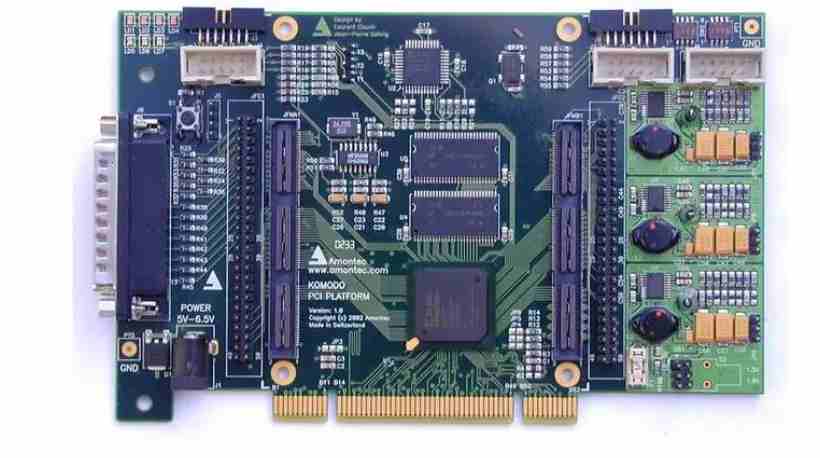

① Check electronic devices in SMT patch factory goods must be repaired in the case of the first to make clear, each spot welding electronic devices whether wrong version, leakage, reverse problems exist, to determine the authenticity of no raw materials is also a must consider the situation, because Jingbang electronic devices imported from Germany in 2011 integrated ic pit, Therefore, the primary source of European countries is not necessarily all stronger than Shenzhen Huaqiang North. If you get rid of errors, leaks, reversions, true and false problems, you can take a circuit board with common faults and first check that the circuit board is intact, that every electronic component is significantly burned out and that there are misplugs.

Most 80% of the circuit board is poor spot welding, spot welding welding is not smooth, whether there is abnormal, first refer to the ISO9001 quality management system management method specification, there are also a variety of SMT production and processing welding product quality standards, check whether there is open welding, false welding, short circuit fault. The copper is not significantly warped so that the human eye can thus see the poor. If so, it is necessary to carry out maintenance on the unsatisfactory points of the commodity. If not, it can carry out the next practical operation.

(3) In this stage of the whole process of the detection of electronic devices, most of us have already cleared the human eye can see some of the poor, now it is still necessary to carefully query diodes, electrolytic capacitors on the circuit board the use of the largest number of components also have other other bits have requirements, or are the provisions of the electronic devices are inserted into the wrong position.

(4) Special tools of electronic devices if all the human eye resolution is no problem, this time we must use some auxiliary software, SMT SMT plant is the most common is to use a digital multimeter simple and accurate measurement of your resistor, capacitor, transistor and other electronic devices, The key to the digital multimeter test is to query the resistor value of this component is not inconsistent with the standard value, increase or decrease, capacitor is not the lead, inductor is not the lead.

After the power supply detection in the whole process of all, most of the basic problems can be removed, the power supply is not easy to be caused by short circuit fault or bridge circuit board burning damage. You can access the switching power supply and check whether the relative function of the circuit board is normal. After most of all steps are completed, you can distinguish and overhaul the unsatisfactory products of customers according to their BOM, Gerber and circuit schematic diagram. In the patch processing plant, the technical personnel of the maintenance unit are the technical professional players carefully selected in the production workshop.

2. What are the actual operating standards of PCBA processing

① In the PCBA work area, there is no need to have all kinds of food and drinks, smoking is strictly prohibited, do not put dirt irrelevant to the work, and maintain the operation table clean and tidy.

② Do not use bare hands or fingers to take the surface of the electric welding in PCBA processing, because each person must metabolize the vegetable oil will reduce malleability, very easy to appear casting defects.

③ The operating process of PCBA and electronic devices should be reduced to a minimum degree to prevent risks. In installation areas where rubber gloves must be used, dirty rubber gloves will cause environmental pollution, so they should be removed and replaced frequently if necessary.

(4) Can not be used to maintain the skin of vegetable oils or a variety of silicone with a detergent, they can lead to malleability and coating bonding characteristics of the problem. There is a professional configuration for PCBA welding surface cleaning agent can be stored.

⑤ Electronic devices and PCbas sensitive to EOS/ESD must be marked with appropriate EOS/ESD labels to prevent confusion with other electronic devices. In addition, in order to avoid serious harm to sensitive electronic devices by ESD and EOS, all actual operation, installation and testing must be carried out on the platform that can operate electrostatic induction.

⑥ Check the EOS/ESD operating platform on time to make sure that they can all work normally (antistatic). A variety of risks to EOS/ESD components can be caused by the wrong way the grounding device is connected or by metal oxides in the connection position of the grounding device. Therefore, special maintenance should be given to the "third wire" grounding device end connector.

⑦ It is strictly prohibited to stack up PCBA, that will produce physical damage, in the assembly work table should be equipped with a special type of fixed support, their classification.

In PCBA processing, we should strictly implement the practical operating standards, appropriate practical operation, to ensure the final application quality of goods, and reduce the destruction of electronic devices, cost control.