With the rapid development of SMT, on the one hand, entrepreneurs, researchers and engineers can find business opportunities, find topics, develop products, promote and drive the development of related industries, and create a large number of employment opportunities. On the other hand, the use of advanced technology and equipment requires a large number of SMT talents who master advanced manufacturing technology as support. So how to train SMT SMT machine technical personnel? To understand how to train SMT SMT machine technical personnel and PCB circuit board welding how to distinguish the relevant knowledge.

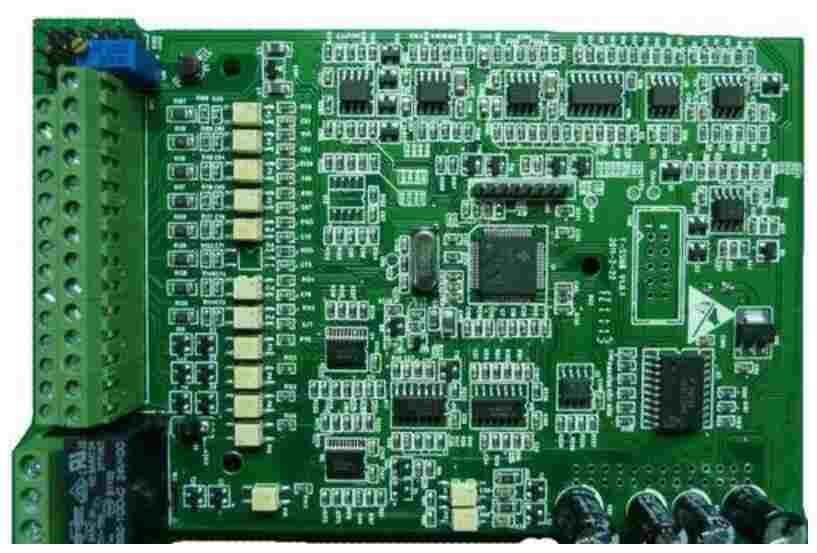

1. How to distinguish the welding quality of PCB circuit board

It is because of the development of the mobile phone and electronic and communication industry, so at the same time to Shenzhen PCB circuit board welding industry is also increasing and rapid growth, leading to the layer number of components and quality and some other things more and more high requirements.

It is precisely because of the fierce price competition in the market that PCB materials are also in a rising trend. As a result, many manufacturers are improving their core competitiveness and monopolizing the market through some relatively low prices. But behind these relatively low prices, the cost of materials and process production is reduced. However, devices are always prone to cracks and scratches and other faults in use, so this situation can seriously affect the weldability of the products used.

So how do we tell these things apart? First of all, we can see what the standard rules of thickness of this size are, because the circuit board has different sizes for some standard thicknesses, so the customer can measure some checks, according to their own product thickness and specifications, and then the light and color, the external circuit board is covered with ink, and then the circuit board can play the role of insulation. If the color of the board is not bright, then the quality of the insulation board itself is not good, so I hope you can choose well when you buy.

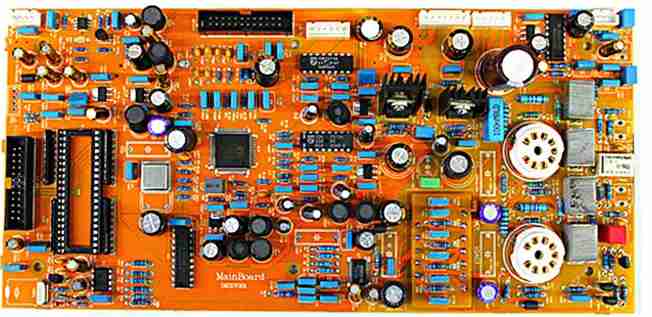

2. How to train SMT SMT machine technical personnel

In recent years, SMT technology is rapidly developed for our country's electronic manufacturing technology mainstream, and has been widely used in the electronic manufacturing industry. The rapid development of SMT, on the one hand, enables entrepreneurs, researchers and engineers to find business opportunities, find topics, develop products, promote and drive the development of related industries, and create a large number of job opportunities. On the other hand, the use of advanced technology and equipment requires a large number of SMT talents who master advanced manufacturing technology as support. So how to train SMT SMT machine technical personnel? Here's what to tell you:

1.SMT skill is a practical and strong skill. The basic knowledge of SMT technology comes not from the school or curriculum, but from the actual environment, from the experience of disciples to teach, help and guide. Any kind of academic explanation that is separate from practical practice and absent from practical practice will not help the healthy growth of SMT teachings. 2. Enterprises on the "gray collar layer" SMT skill talents common sense and ability layout requirements of vocational colleges SMT skill talents for education policy positioning. "Blue-collar" SMT personnel can be trained through secondary vocational education, but also can rely on the enterprise's own efforts for training; "Golden collar" SMT talents need a small amount of practical experience, which cannot be trained by schools alone. 3. Higher vocational colleges through the SMT implementation room configuration, SMT amateur teacher training, the pursuit of school and enterprise help to explain the transformation, can reach the support of the "gray collar layer" SMT talents education as the root premise. Based on the above analysis, it is important for higher vocational colleges to take "gray collar" SMT talents as the training policy. The orientation of talent education should be: Know the basic skills and consumption process of SMT, master the basic functions and use of SMT configuration (including SMT SMT SMT SMT SMT machine/solder paste printing machine/reflow soldering, etc.), have the experience of dominating configuration and finishing, have the exquisite professional essence, Can be engaged in the first line of enterprise consumption SMT configuration dominance, as extensive maintenance, SMT process and production, process document pattern, process process problems rough treatment of reward and punishment, quality control (IQC, IPQC, OQC), material control and other skills of the primary use of talents. According to senior experts, SMT is one of the ten most dynamic technologies in the information industry today. To realize the importance of training smt talents. Now let's talk about the method of training SMT technical talents. The SMT technical talents needed by enterprises can be divided into three levels. Different types of enterprises have different requirements on the three levels of SMT technical talents.

1. "blue-collar" SMT technical talents. "Blue-collar" SMT technical personnel refer to the technical workers who are responsible for the specific operation of smt equipment or process in the production position and have certain knowledge of SMT equipment, SMT materials and chip materials. Corresponding job groups include general managers (such as material managers), equipment or process operators, etc. 2. "Gray collar layer" SMT technical personnel. "Gray collar layer" refers to the technical personnel who are responsible for SMT process, document and quality management and material control on the production line, or the engineering personnel who are responsible for daily operation, testing, maintenance and repair of SMT equipment and have little experience in equipment operation and management. Corresponding job groups include general managers (such as quality control personnel), team leaders, process or equipment technicians, etc. 3. "Golden collar" SMT technical personnel. "Golden collar" refers to experienced engineering personnel with knowledge and ability of SMT basic theory, technology and production process, performance and application of SMT equipment, and SMT process project management. Corresponding job groups include equipment or process assistant engineer, equipment or process engineer, manager or factory director, etc. Compared with the high-speed growing SMT wealth, our country's SMT education and training are lagging behind, whether people's opinions, or growth rate and quality, are far from meeting the growth demands of the SMT wealth. Because the common sense layout and comprehensive ability of employees can not keep up with the growth of skill, the low degree of play, resulting in some enterprise process quality is not good, only the production of low skill products, some enterprises fall into the vicious cycle of price competition. In our country, the corresponding discipline, amateur configuration and didactical training system configuration items just started, as in previous years, the discipline amateur set up by night school can hardly meet the requirements of SMT. According to the rules of explanatory notes, it takes at least three or four years to produce qualified SMT talents. The above is said to introduce here, I hope to help you.