1. How to deal with the quality problems of the patch processing plant

General enterprises are most afraid of quality problems, because it means that the credibility of the enterprise will be greatly damaged, and the enterprise will be faced with a large number of rework, and will waste a lot of materials, so once encountered a lot of this, most of the enterprises are quite nervous, so the problem is dealt with a lot of inappropriate, which leads to the loss of customer sources. Facing the quality problem, SMT patchprocessing factory gives the following suggestions to the major enterprises.

1. Immediately inform the engineer to carry out the corresponding replacement, and at the same time give certain compensation for the loss caused by the customer's quality, of course, not the full compensation.

2. Inform customers that their quality has never been a problem, and then timely inform customers of the treatment of the situation, to give customers a certain degree of reassurance.

3. Then gather all the staff of the company to rework, rework everything immediately, and make the product timely.

4, it is best to give customers certain gifts when sending goods, extinguish their anger.

5, in the late work to invite the customer to dinner, personally apologize. After these actions are done, the customer's anger has disappeared. If this kind of problem is handled properly, I believe that he will definitely buy your product again in the future, and will also introduce the customer to buy, such a service has basically disappeared until now.

2. How to determine the thickness of SMT steel mesh

The thickness of SMT steel mesh is one of the important parameters affecting the solder paste of printed circuit board can be successfully welded in place, so many need to customize the SMT steel mesh are not sure how much thickness they need to SMT steel mesh size. To this end, kingfordSMT manufacturer gives the following answer. "

In fact, the size of SMT steel mesh thickness is mainly determined by the spacing of PCB circuit board welding components. If the spacing is small, the choice of thinner thickness of SMT steel mesh. If the spacing is large, choose the thickness of SMT steel mesh. Special circumstances cannot be ruled out." Here's what Kingford said. After a good in-depth conversation, I learned that determining the thickness of the SMT steel mesh is actually a measurement standard: the size of the SMT steel mesh thickness must meet the fine-spaced QFP and BGA on the printed circuit board, and take into account the smallest CHIP components.

Generally, the thickness of SMT steel mesh is 0.13mm or 0.15mm, and its ratio to the spacing size is 3:2. That is, when the PITCH is 0.4IC and 0.4 and 0.5BGA, the thickness of 0.1mm is adopted; when the PITCH is 0.5 IC and 0.65 BGA, the thickness of 0.12mm is adopted; If the PITCH is 0.65 (including 0.65) or above IC and 0.8 (including 0.8) or above BGA, 0.15mm thickness shall be used. 0.12mm thickness for 0402 components

3. How to select an SMT factory

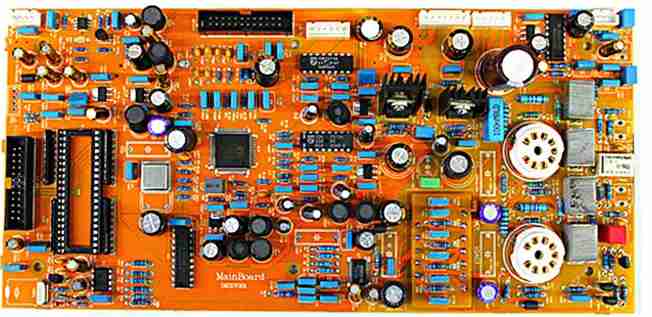

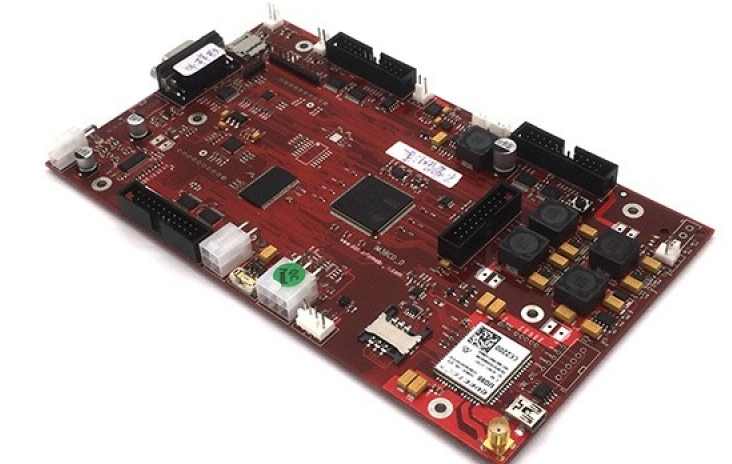

As a link in the entire manufacturing process of electronic products, with highly developed equipment and improved management, the professional Cooperation of SMT processing plant seems to determine whether your PCB board can be delivered on schedule, whether the quality can be controlled and whether it can be repaired in time. The added value is much higher than the unit price difference between 8 and 9 per cent. How to check the cooperation degree of SMT factory? Start with people. Talk with the management and even the boss of the SMT factory to see if they have a sincere attitude and belief. In addition, the third party can also know the reputation of the processing plant and the customer cases served and so on.

2, Quality Control process (Quality Control) Many SMT processing plants in order to reduce the unit price in the market, at the risk of sacrificing quality, reduce QC personnel or do not equip with AOI for testing and other means. In the process of evaluating SMT processing plant, it is necessary to observe and understand in detail whether IQC, post-furnace inspection, QC and other series positions are set up in the warehouse, whether AOI inspection equipment is reasonably equipped, whether it is opened and used, and how engineers introduce quality management methods and documents, etc. Only with a comprehensive understanding, can you ensure that your products can be perfectly processed.

The spiritual outlook of front-line employees and managers determines whether your products can maintain high yield, consistency, etc., because products are made by people or operating equipment. Whether the communication with the manager is smooth, whether there is passion, whether the staff work meticulously, each does his job.

4. Give Up These Audits · Look at factory scale: Unless your order is enough for 100k, any SMT factory can do it · Look at SMT equipment: Unless PCB board has very small material (such as 0201 and below) or complex process (POP, etc.), general factory SMT equipment can be done. · Look at the quotation: If the quotation is slightly out of line at the first glance, one SMT factory will be rejected, and it may be a very good one. Those who dare to say anything are competent and have requirements on quality. The initial quotation can only be referred to, or even not referred to. It is very risky to choose this supplier based on the chest pounding promise of SMT factory or happy chat. Good companies have long-term stable SMT processing plants, but poor companies are always looking for, repeat yesterday's story. It's time to reflect on your purchasing behavior. Grasp the above several methods to select SMT factory, can be in the choice of suppliers without disadvantage.