Name: 2OZ oz aluminum base circuit board

Number of layers: single-sided aluminum substrate

Plate thickness: 2.0MM

Copper thickness: 2OZ oz

Color: white text

Surface treatment: spray tin process

Breakdown voltage: 3000V

Thermal conductivity - thermal conductivity (W/m-k): 2.0

Application field: LED lighting

Thermoelectric separation copper-based circuit board

Name: Thermoelectric separation copper-based circuit board

Plate thickness: 2.0MM

Copper foil thickness: 3OZ

Thermal conductivity: 398w/m.k

Withstand voltage: AC1500V

Solder mask type: white oil

Surface treatment: OSP

E-T test: 100% computer open and short test

Production process: thermoelectric separation process

High thermal conductivity aluminum-based circuit board

Name: High thermal conductivity aluminum base circuit board

Number of layers: single-layer aluminum substrate

Plate thickness: 1.5MM

Copper thickness: 1OZ

Surface treatment: tin spray

Color: white oil black

Thermal conductivity: 3.0 (W/mk)

Withstand voltage KV: 1.5-3.5KV/AC

Application field: mining machine lighting

High thermal conductivity copper substrate

Name: High thermal conductivity copper substrate

Plate thickness: 1.0MM

Copper foil thickness: 2OZ

Withstand voltage: AC2000V

Thermal conductivity: 398w/m.k

Solder mask type: black oil

Surface Treatment: Immersion Gold

E-T test: 100% computer open and short test

Production process: thermoelectric separation process

Product name: Copper base circuit board

Plate thickness: 1.6MM

Copper foil thickness: 2OZ

Withstand voltage: AC2000V

Thermal conductivity: 398w/m.k

Solder mask type: white oil

Surface treatment: OSP

E-T test: 100% computer open and short test

Production process: thermoelectric separation process

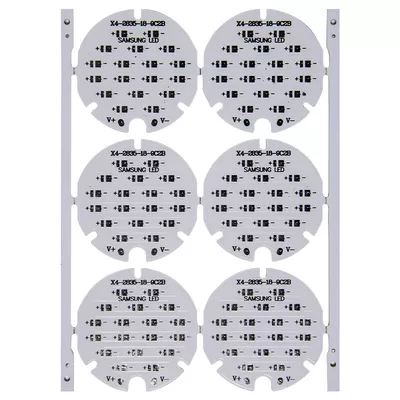

Aluminum Core LED MC Single Sided PCB

Name: Aluminum Core LED MC Single Sided PCB

Layers: 1

Material: Aluminum (metal core)

Thermal conductivity: 0.8, 1.5, 2.0, 3.0 W/mK

Thickness: 0.5-3mm

Copper thickness: 0.5-10OZ

Outline: Wiring, Punching, V-Cut

Solder mask: white/black/blue/green/red oil

Legend/Silkscreen Color: Black/White

Surface treatment: immersion gold, spray tin, OSP

Maximum panel size: 600*500mm

Packing: vacuum/polybag

Application: LED field

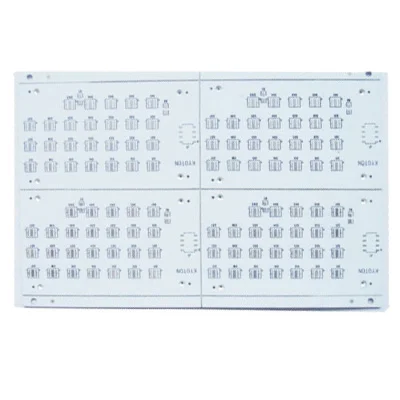

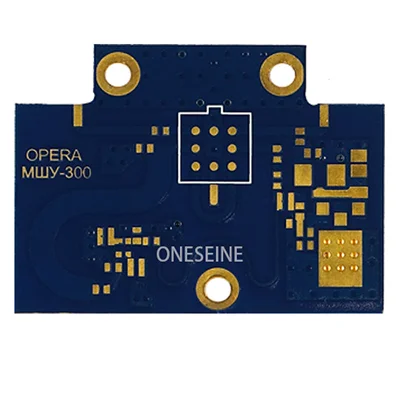

Name: Metal Core Copper Base MC PCB

Number of layers: 2 layers of MCPCB

Material: copper base

Raw materials: aluminum core, copper core, iron core

Size: 8*8CM

There are two types of plated holes:

a) Signal PTH between TOP and BOT side, no connection on Cu core

b) Cool the PTH connected to the copper core.

There are two types of plated holes:

a) Signal PTH between TOP and BOT side, no connection on Cu core

b) Cool the PTH connected to the copper core

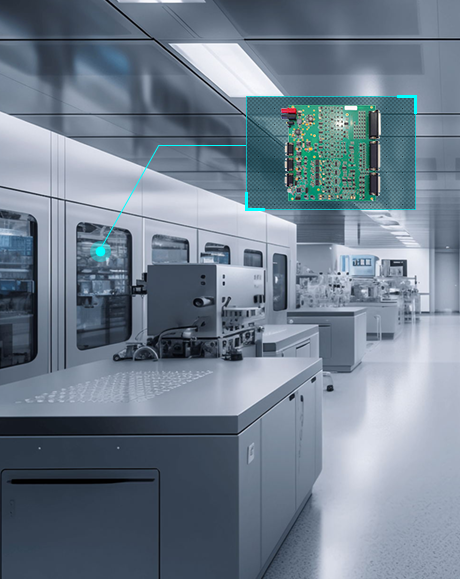

- PCB Manufacturing Equipment

- PCB Capability

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine

| Item | Capability |

| Layer Count | 1-40layers |

| Base Material | KB、Shengyi、ShengyiSF305、FR408、FR408HR、IS410、FR406、GETEK、370HR、IT180A、Rogers4350B、Rogers4000、PTFE Laminates(Rogers series、Taconic series、Arlon series、Nelco series)、Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| Board Type | Backplane、HDI、High multi-layer 、blind&buried PCB、Embedded Capacitance、Embedded resistance board 、Heavy copper power PCB、Backdrill. |

| Board Thickness | 0.2-5.0mm |

| Copper Thickness | Min. 1/2 OZ, Max. 10 OZ |

| PTH Wall | 25um(1mil) |

| Maximum Board Size | 1100*500mm(43”*19”) |

| Min laser drilling size | 4mil |

| Min. Spacing/Tracing | 2.7mil/2.7mil |

| Solder Mask | Green, Black, Blue, Red, White, Yellow, Purple matte/glossy |

| Surface Treatment | Flash gold(electroplated gold)、ENIG、Hard gold、Flash gold、HASL Lead-free 、OSP、ENEPIG、Soft gold、Immersion silver、Immersion Tin、ENIG+OSP, ENIG+Gold finger, Flash gold(electroplated gold)+Gold finger, Immersion silver+Gold finger, Immersion Tin+Gold finger. |

| Min. Annular Ring | 3mil |

| Aspect ratio | 10:1(HASL Lead-free 、HASL Lead、ENIG、Immersion Tin、Immersion silver、ENEPIG);8:1(OSP) |

| Impedance control | ±5ohm(<50ohm), ±10%(≥50ohm) |

| Other Techniques | Blind/Buried Via |

| Gold Fingers | |

| Press Fit | |

| Via in Pad | |

| Electrical Test |