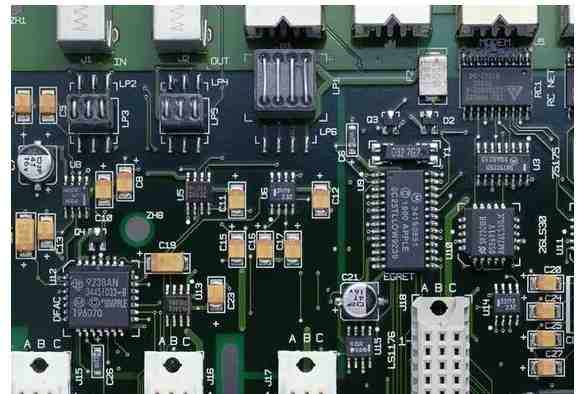

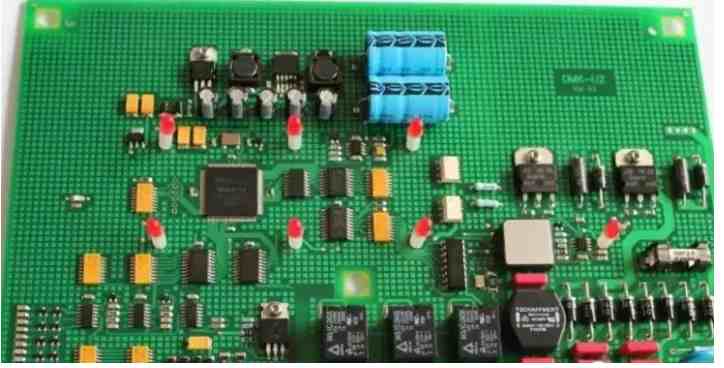

PCBA machining manual welding skills

Welding distanceThe gas generated during welding will cause harm to the human body, so when using a soldering iron, the distance between the nose and the soldering iron should be more than 30cm, and 40cm is a more appropriate distance.