SMT voiding is the process of iding the SMT patch with a gap below the solder spot, resulting in an unsoldered or incomplete weld. This phenomenon will reduce the reliability and connection performance of solder joints, resulting in poor operation and failure of electronic equipment.

The following is the method to judge and solve the SMT patch welding:

Judging virtual welding:

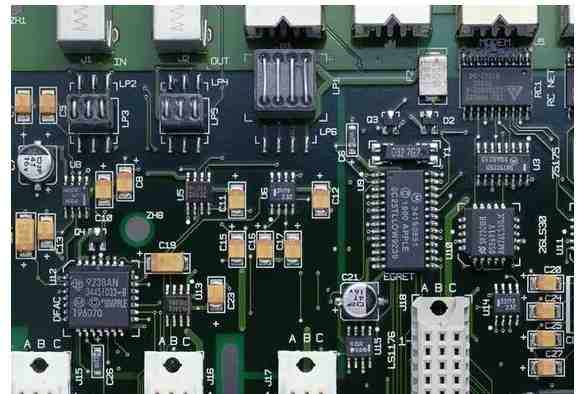

1. Appearance inspection: lack of surface smoothness of solder joints, abnormal color of solder joints or inconsistent size of solder joints.

2. X-ray inspection: Use the X-ray machine to scan the solder joints to see if there are gaps or bubbles below the solder joints.

3. Gold wire measurement: Before and after welding of the SMT patch, the solder joint is measured by gold wire to measure whether there is a gap or bubble under the solder joint.

Solve virtual welding:

1.Control welding temperature: Reasonable control of welding temperature can avoid the formation of bubbles and voids below the solder joint. If the welding temperature is too high, the material below the solder joint will produce gas, resulting in virtual welding.

2. Change the PCB board thickness: Increasing the thickness of the PCB board can increase the heat transfer time and reduce the generation of gas below the solder joint, thus reducing the possibility of virtual welding.

3. Change welding materials: The use of high-quality welding materials can reduce the occurrence of virtual welding. With the right solder alloy and flux, the problem of bubbles below the solder joint can be improved.

4. Optimize PCB board design: Reasonable optimization of PCB board design can reduce the number of welding points, thereby reducing the occurrence of virtual welding.

5. Optimization of welding process: Reasonable optimization of welding process can reduce the fluctuation of welding temperature, thereby reducing the occurrence of virtual welding. At the same time, reasonable control of the welding speed can make the solder better fill the solder joint and reduce the bubbles below the solder joint.

kingford Electronics is a professional PCBA OEM manufacturer, providing one-stop services from upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly, etc.