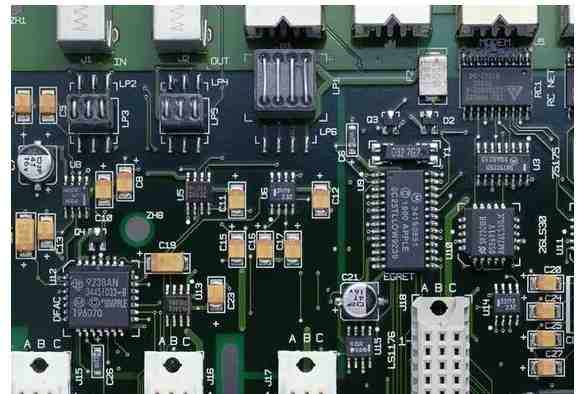

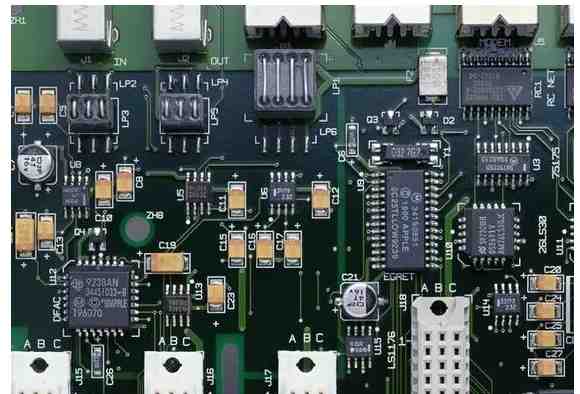

Many SMT factories in the production, often encounter some poor quality,kinhford as a professional third-party SMT processing factory, for everyone to summarize the SMT processing in the most prone to problems of packaging and problems (according to the difficulty) :

(1) QFN: The most likely adverse phenomenon is bridge, virtual welding (open welding).

(2) Pin components: such as SOP QFP below 0.65mm, the most likely adverse phenomenon is bridge, virtual welding (open welding).

(3) Large spacing, large size BGA: the most likely adverse phenomenon is the solder joint stress fracture.

(4) Small spacing BGA: The most likely adverse phenomenon is bridge, virtual welding (open welding).

(5) Long fine pitch surface sticker connector: the most likely adverse phenomenon is bridge, virtual welding (open welding).

(6) Micro switch, socket: the most likely adverse phenomenon is the internal rosin.

The main causes of common problems are:

(1) The bridge of micro-pitch components is mainly caused by poor printing of solder paste.

(2) The solder joint cracking of large size BGA is mainly caused by moisture.

(3) The bridge and virtual welding of small spacing BGA are mainly caused by poor printing of welding paste.

(4) The opening welding of transformers and other components is mainly caused by the poor coplanarity of the component pins.

(5) The bridge and open welding of the long fine distance table attachment connector is largely because the PCB welding deformation is not related to the layout direction of the socket.

(6) The internal entry of rosin into micro switches and sockets is mainly caused by the capillary effect formed by the structural design of these components

Kingford Electronics is a professional PCBA OEM manufacturer, providing one-stop services from upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly, etc.

Why choose Shenzhen Honglijie?

1. Strength guarantee

- SMT workshop: has imported SMT machine, optical inspection equipment, can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

DIP production line: there are two wave soldering, of which there are more than 10 old employees who have worked for more than three years. The workers have high proficiency and can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

- High-end equipment can be attached to precision shaped parts, BGA, QFN, 0201 materials. Also can be template patch, loose material hand.

- Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

- Accumulated service for thousands of electronic enterprises, involving many types of automotive equipment and industrial control motherboard SMT processing services, products are often exported to Europe and the United States, quality can be affirmed by new and old customers.

- Delivery on time, normal 3-5 days after complete materials, small batches can also be expedited on the same day.

4. Strong maintenance ability, perfect after-sales service

- Experienced maintenance engineers, can repair all kinds of patch welding caused by bad products, to ensure the connectivity of each circuit board.

- 24-hour customer service staff is ready to respond, the fastest to solve your order problems.