PCB Board Deformation Hazards

PCB board deformation is usually due to the weight of the circuit board itself caused by the concave deformation of the board or V-Cut depth and connection bar will affect the deformation of the board, PCB board deformation will affect the PCBA processing, the next is to introduce the harm of PCB board deformation. On the automatic surface mount line, if the circuit board is not flat, it will lead to inaccurate positioning, components cannot be inserted or installed on the holes and surface mount pads of the board, and even damage the automatic insert machine.The circuit board on which the components are mounted is bent after welding, making it difficult to cut the component feet neatly. The circuit board cannot be installed in the chassis or the socket in the machine, so the assembly plant encountered circuit board warping is also very troublesome.

The current surface mount technology is developing in the direction of high precision, high speed and intelligence, which puts forward higher requirements for the flatness of PCB boards as the home of various components.

In the IPC standard, it is specifically stated that the allowable deformation of PCB boards with surface mounting devices is 0.75%, while the allowable deformation of PCB boards without surface mounting devices is 1.5%.

In fact, in order to meet the needs of high precision and high-speed placement, some electronic assembly manufacturers have more stringent requirements for the amount of deformation. If required, the amount of deformation allowed is 0.5%, and even some individual requirements are 0.3%.

PCB board is composed of copper foil, resin, glass cloth and other materials. Each material has different physical and chemical properties. After being pressed together, there will inevitably be residual thermal stress, which leads to deformation.

At the same time, in the PCB processing process, high temperature, mechanical cutting, wet processing and other processes will also have an important impact on the deformation of the board. In short, the reasons for PCB board deformation are complex and diverse. How to reduce or eliminate the distortion of material properties caused by different or processing is one of the complex issues facing PCB manufacturers.

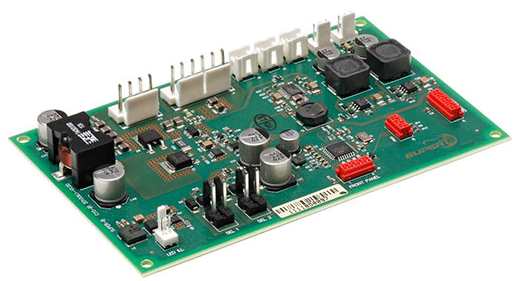

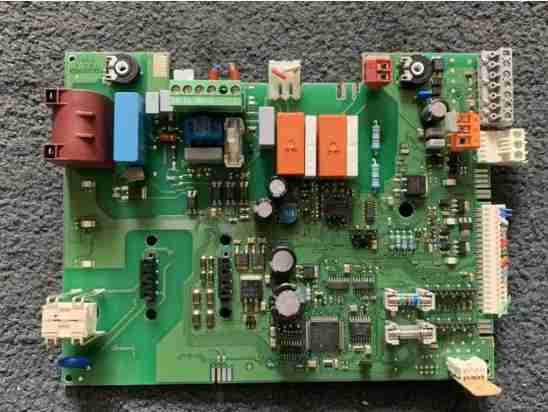

Shenzhen Kingford Technology Co., Ltd. is a PCB factory specializing in printed circuit board manufacturing, 16 years of focus on single, double sided, multi-layer circuit board production. Can provide impedance board, HDI board, blind hole board and other multi-layer PCB board proofing, small batch production business. The production requirements of SMT chip processing are relatively high, because in PCBA processing, whether it is patch processing or other processing technology, it is a relatively precise type of processing, and there can be no errors and poor processing. Since there are many processing procedures involved, many requirements need to be carried out throughout the processing and production process. For example, it is necessary to quota management of solder paste, repair glue and component losses, and control factors such as process parameters, process, personnel, equipment, materials, process testing and shop environment.

The high quality requirements of SMT chip processing require us to apply a clear work responsibility system, such as the SMT chip processing related position operators need to conduct professional training, and implement the first piece inspection, self-inspection, mutual inspection and inspector inspection system.

Production requirements for SMT patch processing

1. The production site setting is reasonable, the mark is correct; Warehouse materials and products in process shall be sorted and stacked neatly in accordance with the ledger.

2. Product batch management: The nonconforming product control procedures shall clearly specify the isolation, identification, recording, review and treatment of nonconforming products. Generally, rework should not exceed three times, and component rework should not exceed two times.

3. Civilized production: clean, no debris, civilized operation, no barbaric and disorderly operation. Site management must have system, inspection, evaluation and record, and carry out "6S" (classification, rectification, cleaning, cleaning, literacy, service) activities every day.

4. The maintenance and maintenance of SMT processing equipment: key equipment should be regularly checked by full-time maintenance personnel, so that the equipment is always in good condition, tracking and monitoring the status of the equipment, timely detection of problems, take corrective and preventive measures, timely maintenance and repair.