I. SMT proofing technology and hardware

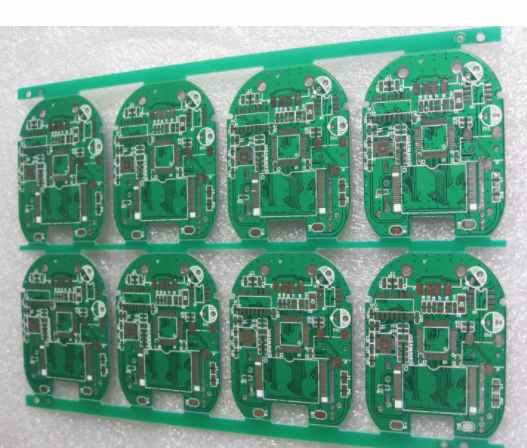

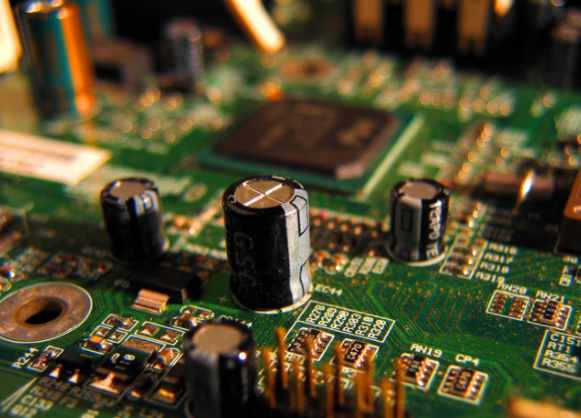

SMT proofing Technology refers to the technology of installing electronic components on the circuit board, mainly refers to the SMT(Surface Mount Technology) SMT components installed on the circuit board by the SMT mounter. SMT proofing hardware includes SMT machine, solder paste printing machine, high and low temperature oven, X-ray detection machine, AOI detection machine, screw machine, etc. Each hardware has its own function and role, can effectively achieve the requirements of SMT proofing.

Two, SMT proofing process

The process of SMT proofing mainly includes preparation, PCB surface wiring, PCB surface removal components, solder paste printing, patch component installation, X-ray testing and AOI testing. Each link needs to be operated in a standard way to ensure the quality of SMT proofing.

Three, SMT proofing requirements

a. Technical requirements: must be familiar with SMT proofing process, understand circuit principle, master SMT proofing operation technology, familiar with SMT proofing equipment operation;

b. Patience requirements: The SMT proofing operation requires a certain amount of patience. In the operation, it is necessary to be careful and prudent, and carefully check the size and position of components to ensure the quality;

c. Quality requirements: no breaking, no tin leakage, no foot falling, no corner, etc., shall be required after the proofing is completed to ensure the quality level of proofing;

d. Accuracy requirements: During the proofing process, it is necessary to master the accuracy of the installation position and ensure the accuracy of the installation position and dimension between components to ensure the accuracy of the overall circuit design.

Four, SMT proofing quality control

a. In the process of proofing, it is necessary to check the quality of the solder paste and components used to ensure the quality;

b. Regular maintenance and maintenance of SMT equipment is required to ensure the stability of the equipment;

c. The quality of SMT proofing should be tested regularly to ensure the accuracy of the proofing;

d. It is necessary to establish the quality inspection standard of SMT proofing to ensure the qualified rate of proofing;

e. Regular training is required for SMT proofing operators to improve their proofing skills.

V. Selection of SMT proofing

a. The type of SMT proof machine shall be determined according to the type, quantity and size of the components designed by oneself;

b. Determine the type of equipment suitable for your own production needs;

c. According to the production capacity, determine the appropriate number of equipment;

d. Consider the investment cost of equipment and determine the suitable brand of equipment;

e. Consider the maintenance cost of the equipment and determine the suitable service life of the equipment.

Vi. Application of SMT proofing

SMT proofing technology plays an important role in the manufacture of electronic products. It can provide designers with a lot of convenience. It can use small-size components to design and manufacture products more quickly. At present, SMT proofing technology has been widely used in consumer electronics, automotive electronics, communication electronics, aerospace, security monitoring, medical equipment and other industries

2. SMT OEM service advantages and processes!

I. Advantages of SMT OEM service

SMT Foundry services provide an efficient, economical and reliable manufacturing service, providing customers with more freedom and greater creativity.

1. Save time and cost: SMT foundry services can save time and cost for customers, and help customers to deliver products faster, rather than spend a lot of time and cost to complete.

2. Better quality: SMT OEM service can provide customers with better product quality, because SMT OEM service manufacturers have more equipment and technology, and can control product quality more accurately.

3. Stronger technical support: SMT OEM service can provide customers with stronger technical support, because SMT OEM service manufacturers have more technical personnel, so they can provide customers with more comprehensive technical support.

4. Faster delivery: SMT Foundry services can provide customers with faster delivery times because the SMT foundry service manufacturer has more equipment and can complete the product faster.

SMT foundry

Ii. Technical requirements of SMT OEM service

SMT OEM service has certain technical requirements. Customers must pay attention to the following points when using SMT OEM service:

1.SMT OEM service requires customers to provide accurate product parameters and assembly drawings, so that SMT OEM service manufacturers can accurately understand customers' product requirements;

2.SMT OEM service requires customers to provide professional process flow, so that SMT OEM service manufacturers can more accurately understand the manufacturing process of products;

3.SMT OEM service requires customers to provide sufficient materials and parts, so that SMT OEM service manufacturers can more accurately meet customers' requirements;

4.SMT OEM service requires customers to deliver products on time, so that SMT OEM service manufacturers can complete product manufacturing faster;

5.SMT OEM service requires customers to provide detailed finished product test reports, so that SMT OEM service manufacturers can know the quality of products more accurately.

Iii. Process of SMT OEM service

1. Order confirmation: Customers need to communicate with SMT OEM service manufacturers to confirm orders according to their product requirements;

2. Technical preparation: SMT OEM service manufacturers shall prepare corresponding technical solutions according to customer's product parameters and assembly drawings;

3. Material procurement: SMT OEM service manufacturers purchase materials and parts according to customers' product requirements;

4. Production and manufacturing: SMT OEM service manufacturers will manufacture products according to customer's product parameters and assembly drawings;

5. Testing quality: SMT OEM service manufacturers shall test the quality of products according to customers' product requirements;

6. Product delivery: SMT OEM service manufacturers deliver products on time according to customers' requirements.