I. Definition of SMT patches

SMT is a technology used in the packaging of electronic components, mainly refers to the use of automatic SMT machine components, such as integrated circuits, resistors, capacitors, etc., directly mount on the printed circuit board, complete the circuit packaging process.

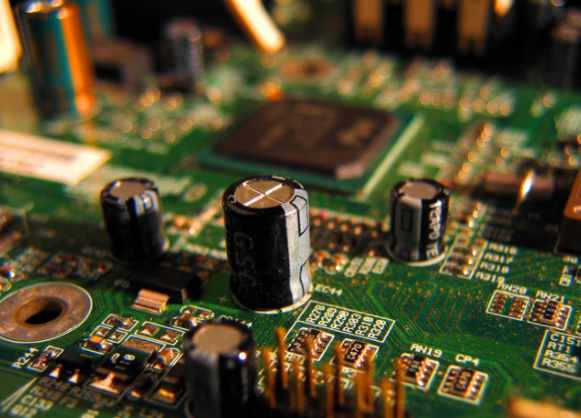

SMT patch

Second, the advantages of SMT patches

1. Compared with traditional plug-in packaging technology, SMT can make products smaller in size and lighter in weight;

2. SMT SMT packaging technology can improve the density of components, thus reducing the area of printed circuit board and saving costs;

3, SMT technology can improve the reliability of the circuit, because SMT technology can effectively improve the packaging density of the circuit, thus reducing the failure rate of the circuit;

4. SMT technology can reduce the processing time, thus improving the production efficiency of products;

5, SMT technology can increase the diversity of components, so as to make the circuit design more flexible;

6. SMT technology can reduce production costs and improve market competitiveness.

Three, the application of SMT patches

1. SMT SMT technology is mainly used in the packaging of electronic components, such as integrated circuits, resistors, capacitors, etc.

2. SMT technology can also be applied to the packaging of microcomputer systems, network systems and control systems;

3. SMT technology can also be applied to the packaging of communication equipment, measuring instruments, security systems and other equipment;

4. SMT technology can also be applied to the packaging of automotive electronic systems, medical equipment and household appliances;

5. SMT technology can also be applied to the packaging of aviation, aerospace and military systems;

6. SMT technology can also be applied to the packaging of solar panels and space electronic equipment.

Iv. SMT Patch process

1. Cleaning: First clean the surface pollutants to ensure the quality of packaging;

2, prewelding: prewelding technology can improve the positioning accuracy of components, so as to reduce the damage rate of components;

3. Patch: Using automatic patch machine, the components are pasted on the printed circuit board;

4, welding: using automatic welding machine, the components are fixed on the printed circuit board;

5. Detection: Automatic detection machine is used to detect the packaging quality of components;

6, assembly: after the completion of the above process, you can complete the circuit packaging assembly.

V. Quality control of SMT patches

1. Use precision testing instruments to test the installation quality of components to ensure the quality of components;

2. Strict quality assurance system is adopted to ensure the packaging quality of components;

3. Adopt hierarchical management mode to control the encapsulation of components at different levels;

4. Adopt effective quality control procedures to carry out unified management of packaging quality of components;

5. Adopt effective quality improvement measures to solve the problems existing in packaging quality in time;

6. Adopt perfect quality recording system to record the changes of packaging quality in time for analysis and research.

Vi. Safety of SMT patches

1. Adopt perfect safety measures to prevent the occurrence of electrical safety accidents such as over voltage, over current and short circuit;

2. Adopt perfect quality inspection procedures to ensure the safety of components;

3. Strict temperature control system is adopted to ensure the safety of components;

4. Adopt effective maintenance measures to ensure the safety of the patch machine;

5. Adopt perfect safety protection measures to protect the safety of operators;

6. Adopt effective safety technology to ensure the safety of customers' products.

2. Five implementation steps of SMT patch processing technology

I. SMT patch processing technology and process characteristics

1. SMT processing technology integrates automation, high speed and precision. It is a technology of placing parts automatically on PCB board from scroll, which is an emerging SMT technology in recent decades.

2, patch processing technology has the characteristics of fast patch speed, high precision, low energy consumption, low production cost, suitable for mass production, is conducive to improving production efficiency and cost saving.

3. SMT patch processing technology not only improves the stability and reliability of products, but also reduces the manufacturing cost of products, which can meet the needs of large-scale mass production.

Ii. Implementation steps of SMT patch processing technology

1. Design the patch equipment: design the patch equipment according to customer requirements to ensure that the patch equipment can meet customer requirements.

2. Installation and debugging of the patch equipment: install the patch equipment and conduct parameter debugging to ensure the smooth operation of the patch equipment in actual use.

3. Patch processing: patch processing according to customer requirements to ensure the quality of the patch.

4. Patch quality inspection: Check the patch quality to ensure that the quality of the patch meets customer requirements.

5. Patch delivery: According to customer requirements, organize the delivery of patches to ensure that customers can obtain patches timely.

3. Advantages of SMT patch processing technology

1, improve product reliability: SMT SMT processing technology can improve the reliability of products, so as to meet customer needs.

2. Reduce product manufacturing costs: SMT SMT processing technology can reduce product manufacturing costs, thereby reducing product costs and improving production efficiency.

3. Improve product stability: SMT patch processing technology can improve product stability, so as to meet customer requirements.

4. Improve the automation level: SMT SMT processing technology can improve the automation level of the production process, so that the production is more efficient and high quality.

5. Shorten the production cycle: SMT patch processing technology can shorten the production cycle of products, thus improving production efficiency.