I. Definition of SMT OEM

SMT OEM refers to the surface mounting technology of small electromechanical equipment. It refers to the installation of electronic components, such as transistors, integrated circuits, and connecting lines, in accordance with a certain pattern through hot fusion welding, so as to complete a complete electronic equipment.

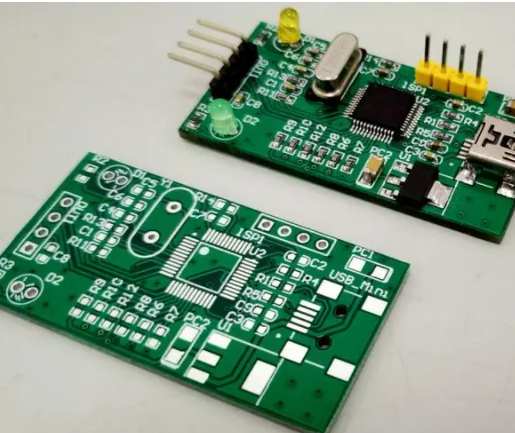

SMT foundry

Ii. Process of SMT OEM

The specific process of SMT OEM is mainly divided into eight steps: application requirement analysis, design confirmation, material preparation, production preparation, PCB cleaning, SMT mounting, SMT welding, testing and so on.

1. Application demand analysis: collect customers' usage requirements, such as specific functions, specifications, colors, sizes, etc. of products, as well as customers' budget, delivery date and other information;

2. Design confirmation: design products according to customer needs, and determine the specific specifications of products;

3. Material preparation: Prepare raw materials needed for production, including PCB board, electronic components, and equipment for mounting and welding;

4. Production preparation: according to product design, prepare the equipment needed in production, such as patch machine, welding machine, etc.;

5.PCB cleaning: used to clean PCB board and remove the dirt on its surface;

6.SMT mounting: Mount the electronic components on the PCB board using the mounting machine;

7.SMT welding: Use welding machine to fix electronic components on PCB board;

8. Test and test: test the finished products to ensure their quality.

3. Common problems in SMT OEM

During SMT agent work, there will be some common problems, mainly including the following:

1. Unqualified surface mounting technology: such as incorrect placement of patches, unqualified amount of welding, etc.;

2. The quality of electronic components is unqualified: because the quality of electronic components is unqualified, it is easy to lead to the quality of products is unqualified;

3. Poor production environment: because the temperature, humidity and other conditions of the environment do not meet the requirements, it is easy to lead to unstable product quality;

4. Unqualified production equipment: due to the insufficient performance of the equipment or the failure of the equipment itself, it is easy to lead to the unqualified quality of the product;

5. Unqualified personnel operation: due to insufficient personnel operation technology, or negligence in the operation process, it is easy to lead to unqualified product quality;

6. Unqualified testing: Due to unqualified testing process or inaccurate testing equipment, it is easy to lead to the quality of products cannot meet the requirements.

2. Analyze the advantages and disadvantages of the patch factory

First, the advantages of the patch factory

1. The SMT plant adopts advanced equipment and technology to provide high quality products. The equipment and technology of the patch factory can meet the different needs of users, and can provide higher product quality and accuracy.

2. The production environment of the patch factory is more standardized, which can meet the different requirements of customers. The quality management system and safety management system of the patch plant can ensure the stability and reliability of production.

3. The patch service of the patch factory can meet the different requirements of customers, and can meet the different needs of customers, and can provide fast service to ensure that the needs of customers can be met.

4. The patch factory has invested a lot of resources, technology and talents to provide efficient products and services to ensure that the needs of customers can be met.

Patch factory

Two, the shortcomings of the patch factory

1. The SMT technology of the SMT plant has certain limitations, which can not meet the high requirements of customers, and sometimes there will be product quality problems.

2. The imperfect technological process and the lack of systematic management of the patch factory may lead to the decline of product quality.

3. The production capacity of the patch factory is limited to a certain extent, and it cannot meet the large demand of customers, resulting in the inability to timely complete the orders of customers.

4. The product cost of the patch factory is relatively high, and the profit margin of customers is limited to a certain extent.

Iii. Improvement path of the patch factory

1. Introduce advanced equipment and technology to improve the quality and accuracy of patch service.

2. Optimize the production environment of the patch plant, improve the quality management system and safety management system, and fully guarantee the product quality.

3. Improve the production capacity of the patch plant to meet the large demand of customers and improve the reliability of products.

4. Optimize the product cost of the patch factory, improve the profit margin of customers and increase their satisfaction.

3. What are the application fields of SMT patch processing

I. Technical characteristics of SMT patch processing

1, high precision: SMT patch processing is based on surface mounting, its positioning accuracy is high, can position the components in sub-millimeter level, which makes it has a great advantage in mounting small components.

2, save material: SMT processing technology is used in semiconductor devices surface-mount technology, can effectively save raw materials, therefore, greatly reduces the production cost.

3. High speed: SMT patch processing adopts automatic mounting, faster than the traditional welding technology, the speed can reach more than 20,000 times per minute, to meet the requirements of mass production.

SMT patch processing

Two, SMT patch processing application field

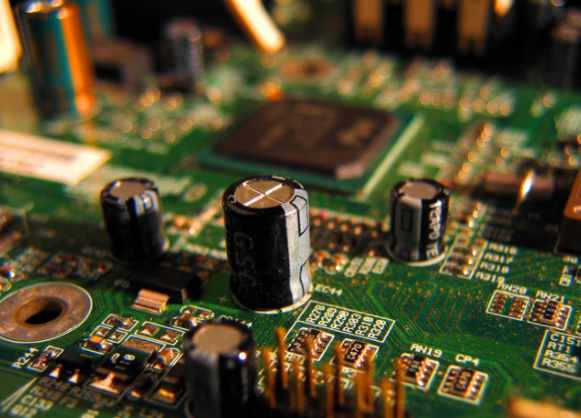

1, electronic industry: SMT SMT processing technology has a wide range of applications in the electronic industry, because of its high precision and material saving characteristics, is widely used in the installation of electronic components, such as circuit boards, integrated circuits, capacitors, resistors, etc.

2, military industry: military industry products need high precision and reliability, SMT patch processing technology is to meet this demand, therefore, in the military industry also has a wide range of applications.

3. Biomedicine industry: SMT patch processing technology is also widely used in biomedicine industry due to its features of raw material saving and high precision, mainly used in medical equipment, biological electronic testing instruments and other products.

Three, SMT patch processing process

1. Cleaning: The first step of SMT patch processing is cleaning. Through the cleaning machine, the ink, dust and other dirt on the circuit board can be effectively removed to ensure the clean and dust-free surface of the circuit board.

2. Positioning: Next, positioning needs to be carried out. The positioning of components is the key of SMT patch processing.

3, mounting: after the positioning is completed, it can be mounted. When mounting, it is necessary to control the spacing between the components and the circuit board to ensure the effect of the patch.

4, testing: Finally, we need to test the product to ensure the quality of the product. In the test, we can test the electrical performance of the circuit board and the function of the components to ensure the quality of the product.