Patch processing is a new technology, which can help us to complete complex assembly tasks more efficiently. So, how exactly does it work? What are its advantages? What does that mean in practice?

First, the principle of patch plug-in processing

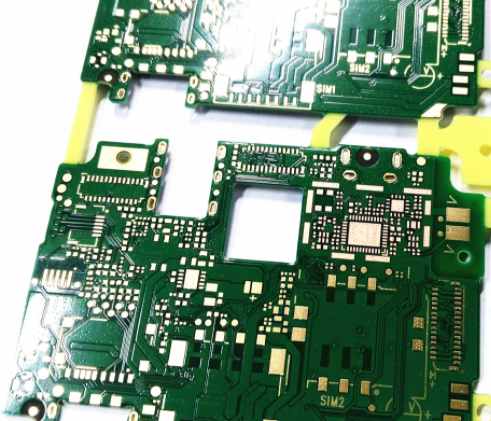

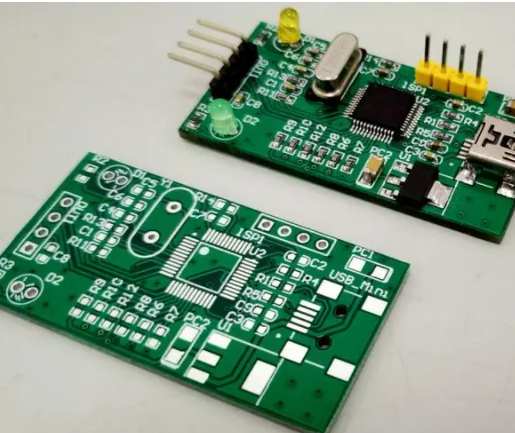

The basic principles of the patch plug-in machining technique can be boiled down to three steps: plug-in, welding and testing. First, the patch components are attached to the substrate, the required components are installed, and then these components are welded to the substrate, and finally tested to ensure the quality of the components.

Two, the advantages of patch plug-in processing

Patch plug-in processing technology has many advantages, among which the main advantages are as follows:

(1) High precision: patch plug-in processing can achieve high precision assembly, within the accuracy range of 0.1mm, can achieve accurate assembly;

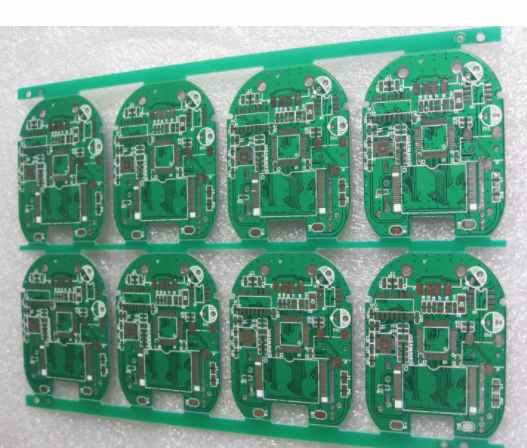

(2) Fast speed: the SMT plug-in processing adopts automatic technology, which can effectively improve the production efficiency and greatly accelerate the production speed;

(3) Low cost: there is no manual operation in the processing of patch plug-in, so the cost is very low;

(4) High efficiency: SMT plug-in processing can realize automatic operation, improve production efficiency and reduce manual operation;

(5) High reliability: patch plug-in processing can ensure the assembly quality, effectively improve the reliability.

Three, the application of patch plug-in processing

Patch plug-in processing technology can be applied to electronic products, automotive, aviation and aerospace industries, among which the application range includes:

(1) Electronic products: the patch plug-in processing of electronic products can realize high-precision assembly, so as to improve the quality and reliability of products;

(2) Automobile: automotive patch plug-in processing can help the automobile industry greatly improve production efficiency and reduce production costs;

(3) Aerospace: The aerospace industry can greatly accelerate the product assembly process and improve work efficiency through patch plug-in processing technology;

(4) Other industries: patch plug-in processing technology can also be applied to smart home, medical devices, robots and other industries.

To sum up, patch plug-in processing technology is a kind of emerging technology, it can effectively improve production efficiency, reduce production costs, improve product quality and reliability, improve the efficiency of enterprises, and can be applied to a number of industries, has a wide range of application prospects.

2. Introduction to the principle and advantages of patch plug-in processing

Patch processing is an efficient and simple technique that produces precise parts that can be mass-produced on a production line. So, what exactly is the patch plug-in processing? What are its advantages? In this article, the principles and benefits of this technique are described in detail.

First, the principle of patch plug-in processing

Chip machining is a technology that uses mechanical control to manufacture precise parts. It is mainly the use of mechanical devices to cut the patches from the raw materials, and then according to the design drawings after positioning, and then the control manipulator will install these patches on the PCB board, forming a complete part.

Two, the advantages of patch plug-in processing

1. High accuracy: patch plug-in processing can realize high-precision parts processing, which can reach the micron level accuracy, and the accuracy will not be affected by the external environment, so it can meet most of the precision parts processing requirements.

2. High processing efficiency: patch plug-in processing can realize efficient parts processing, can complete a large number of parts processing in a short time, greatly improving the production efficiency.

3. Convenient operation: patch plug-in processing can realize automatic processing, without manual participation, the operation is very simple, and can automatically adjust the processing speed, can effectively save manpower, improve production efficiency.

4. Low cost: the cost of patch plug-in processing is lower than the traditional machining technology, which can effectively reduce the production cost and is more economical.

5. A wide range of processing: patch plug-in processing can realize a variety of shapes of parts processing, from precision small parts to large parts processing, with a wide range of processing.

In short, patch plug-in processing is a kind of technology with high accuracy, high processing efficiency, convenient operation, low cost, wide processing range and other advantages, can effectively improve production efficiency, reduce costs, is a very practical technology.