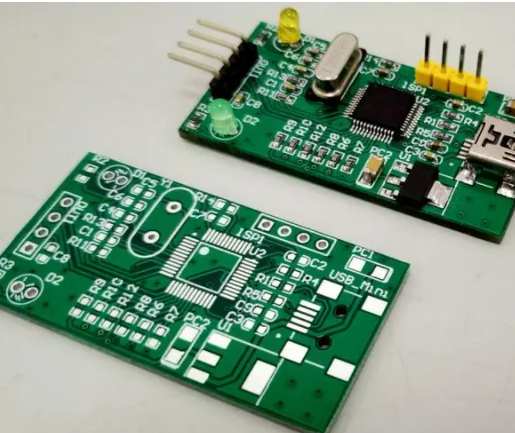

SMT patch machining is an assembly process for small electronic component integration. Its main function is to attach the chip to the circuit board, using the printed circuit board (PCB) to make the final electronic parts. SMT is often used to manufacture computers, home appliances, electronic game consoles and consumer electronic products. So how does SMT patch processing work?

I. Working principle of SMT placing machine

SMT mounters work by attaching chips to a PCB and then attaching them to the PCB with hot glue to form a complete electronic component. Usually, the chip is attached to the PCB using a technique called "hot press welding", which uses a special hot press solder to perfectly bond the chip to the surface of the PCB.

Two, the composition of SMT placing machine

SMT SMT machine is composed of several parts, including: the body of the SMT machine, the SMT head, the patch stand, the patch plate, the blender, the soldering system, the cleaning machine, the patch software, the testing system, etc. Among them, the body of the patch machine is the core part of the patch processing, which is responsible for the chip to the PCB, the chip head is responsible for positioning and adjusting the position of the chip, the patch rack is used to install the chip, the patch plate is used to assemble the chip on the PCB, the mixer is used to evenly apply the hot melt adhesive on the surface of the chip and PCB, the solder system is used to fix the chip and PCB together. The cleaning machine is used to clean the PCB surface, the patch software is used to control the operation of the patch machine, and the detection system is used to test the working effect of the patch machine.

3. Advantages of SMT patch processing

SMT patch processing technology has the advantages of high efficiency, low cost, high precision, high reliability, flexibility and so on, making it the most popular small electronic components integrated assembly process. SMT chip processing technology can accurately position the chip, which makes the chip and PCB perfectly together, thus greatly improving the performance and reliability of PCB. SMT SMT technology also has the advantage of high efficiency, which can greatly shorten the product manufacturing cycle, so as to meet customer needs. In short, SMT SMT processing technology has a unique advantage in the integrated assembly process of small electronic components, which can effectively improve the quality and efficiency of products and provide customers with better service.

2. How to obtain better processing effect of patch plug-in?

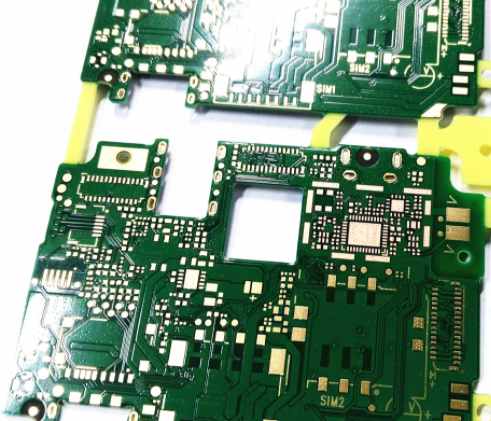

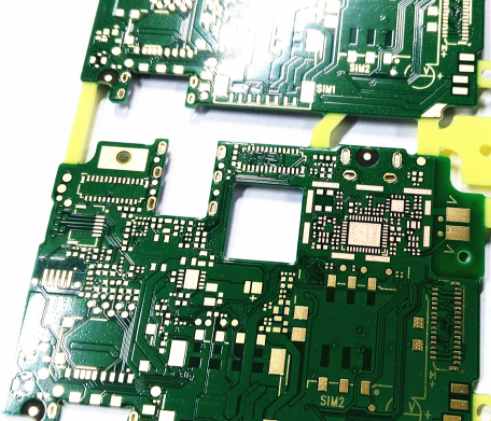

In recent years, patch plug-in processing technology has gradually become the most widely used processing technology in the electronics industry. It can implant small sensors, chips, microelectronic components into the circuit board, making electronic products more miniaturized, advanced, strong functionality. So, how to obtain the best patch plug-in processing effect?

First of all, to choose the appropriate patch plug-in processing technology. Patch plug-in processing technology mainly includes hot pressing welding, laser welding, pressure welding, ultrasonic welding and so on. Among them, hot pressing welding and laser welding are the two most commonly used patch plug-in processing technology. Hot pressing welding is the chip plug-in with hot pressing device fixed on the circuit board, welding on the circuit board, welding effect is better, lower processing cost, but also can achieve high precision welding; In laser welding, the laser beam emitted by the laser is precisely fused between the chip plug-in and the circuit board, which can achieve higher welding accuracy and patch quality, but also produce larger processing costs.

Secondly, to choose a high-quality chip plug-in. As chip plug-in is the key part of patch plug-in processing, the quality of chip plug-in is a major factor affecting the effect of patch plug-in processing. Generally speaking, the better the quality of chip plug-in, the higher the processing quality of patch plug-in, the better the processing effect.

Thirdly, effective patch plug-in processing technology should be implemented. Patch plug-in processing technology mainly a little glue, patch, welding and so on. Among them, dispensing is the chip plug-in fixed on the circuit board, to achieve the contact between the chip plug-in and circuit board; Patch is the chip plug-in is attached to the circuit board to achieve the contact and sealing between the chip plug-in and the circuit board; Welding is the welding between chip plug-in and circuit board, in order to achieve the contact and sealing between chip plug-in and circuit board. In order to obtain the best processing effect of patch plug-in, it is necessary to use the appropriate processing technology of patch plug-in in order to achieve the best processing effect.

Finally, effective quality control of patch plug-in processing should be implemented. For the processing of patch plug-in, quality control is very important. Only through effective quality control can we ensure the processing quality of patch plug-in, so as to obtain the best processing effect.

Through the above points, we can understand the key factors of patch plug-in processing, and how to obtain the best patch plug-in processing effect. Selecting appropriate chip plug-in processing technology, high quality chip plug-in, effective chip plug-in processing technology and effective quality control can effectively ensure the quality of patch plug-in processing, so as to obtain the best processing effect.