Modern electronic equipment production is inseparable from SMT SMT processing technology, but what is SMT SMT processing in the end? What are the characteristics and advantages of its patch processing technology?

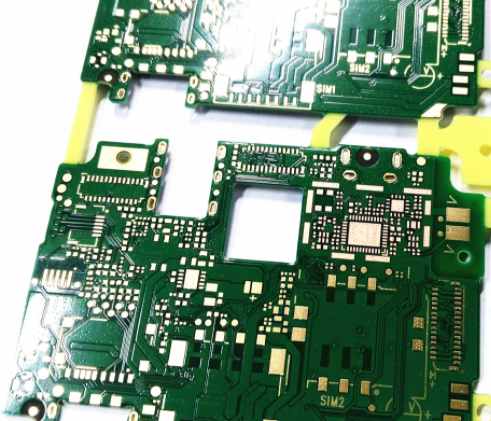

SMT patch processing is the abbreviation of Surface Mount Technology, also known as surface mount technology, is a kind of technology for fixing electronic components on the printed circuit board surface, which is fixed by hot pressing and other ways to complete the installation and welding of electronic components. Connecting electronic device chips, components, and patches together as a whole.

I. SMT patch processing characteristics

1. Strong environmental resistance: SMT patch processing is completed by high-precision automatic mechanical arm, which can better meet the complex environment of electronic equipment. Moreover, the surface mounting of chips and components can reduce the physical vibration and thermal difference of electronic components and ensure the reliability of equipment.

2. Low cost: SMT patch processing is completed by automatic mechanical arm with high precision, and can complete a large number of patch operations in one time, which greatly improves production efficiency, shortens the production cycle and reduces the production cost.

3, small space occupation: Because SMT SMT SMT processing using surface mounting technology, component size can be reduced, the volume of electronic equipment can be reduced, and the space utilization rate is higher.

4. High reliability: SMT patch processing is completed by high-precision automatic mechanical arm, which can better meet the complex environment of electronic equipment, and the surface mounting of chips and components can reduce the physical vibration and thermal difference of electronic components, and ensure the reliability of products.

Two, SMT patch processing advantages

1. High efficiency: SMT patch processing adopts high-precision automatic mechanical arm, which can complete a large number of patch operations at one time, greatly improving the production efficiency, shortening the production cycle and improving the production quality.

2. Cost saving: Due to the adoption of high-precision automatic mechanical arm for SMT patch processing, a large number of patch operations can be completed at one time, which greatly improves the production efficiency, shortens the production cycle and reduces the production cost.

3. Strong extensibility: SMT patch processing adopts surface mounting technology, component size can be reduced, the volume of electronic equipment can be reduced, the space utilization rate is also high, can realize the expansion and upgrade of electronic equipment functions.

Summary: SMT patch processing is a technology of fixing electronic components to the printed circuit board surface. It has the characteristics of strong anti-environmental ability, low cost, small space occupation and high reliability. It can greatly improve the production efficiency, reduce the production cost, improve the scalability, and is an essential technology for the production of electronic equipment.

2. Introduction to three key steps of SMT patch processing

SMT SMT is a kind of electronic component manufacturing technology. It can put small electronic components on the circuit board, so as to achieve the integrity of the circuit board. It is one of the most important manufacturing technologies in the electronics industry. SMT patch processing involves three key steps: placement, welding, and testing.

1. Place:

Placement technology is the first step of SMT patch processing, it involves SMT components into the circuit board, and then put it into the hole on the, its basic principle is to use the mechanical arm of the placement machine to grab components, according circuit board to the design requirements placed on the circuit board. The accuracy of the placement technique is very important because the placement of components directly affects the function of the board.

2. Welding:

The welding technique is the second step of SMT patch machining. It involves welding the placed components to the circuit board to ensure a solid connection between the components and the circuit board. Welding technology includes two kinds of hot welding and cold welding. Their basic principle is to use the manipulator of the welding machine to grab the components and weld them to the circuit board according to the design requirements.

3. Test:

The test technique is the third step of SMT patch machining. It involves testing the circuit board after welding to ensure that the function of the circuit board meets the design requirements. The basic principle of the test technology is to use the manipulator of the test machine to grab the circuit board, according to the design requirements of the circuit board to test, to ensure that the function of the circuit board is normal.

As you can see from the above, SMT patch processing consists of three key steps: placement, welding, and testing. The accuracy of the placement technique is very important, because the placement position of the component directly affects the function of the circuit board; Welding technology includes two kinds of hot welding and cold welding, their basic principle is to use the manipulator of the welding machine grab components, according to the design requirements of the welding to the circuit board; The basic principle of the test technology is to use the manipulator of the test machine to grab the circuit board, according to the design requirements of the circuit board to test, to ensure that the function of the circuit board is normal.

SMT patch processing is a complex manufacturing process, which can patch small electronic components onto the circuit board, so as to achieve the integrity of the circuit board. It is one of the most important manufacturing technologies in the electronics industry. SMT patch processing consists of three key steps: placement, welding and testing, their basic principles and technical requirements are very important, is the realization of the circuit board function of the key link.