Origin; Origin: China

Certification: UL, CE, RoHS

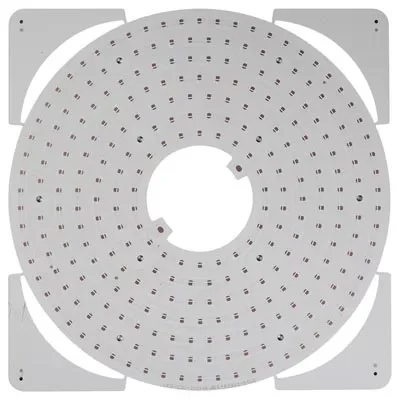

Model: growth light pcb05

Base material: aluminum

Board thick: 1.0/1.2/1.6mm

Copper thick: 0.5-3oz

Print circuit board certificate: ISO9001: 2008, RoHS, UL

Component type: patch ThT DIP

Surface treatment: HASL Leadless

Application: LED growth light bar

Basic Information

Origin; Origin: China

Certification: CE, ROHS, UL

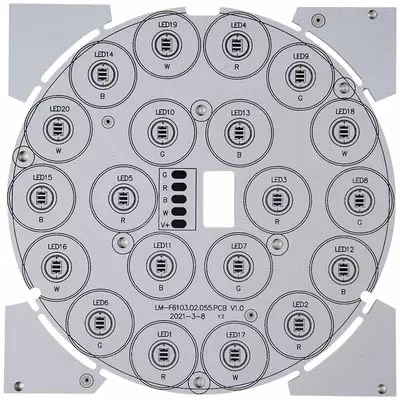

Model: Aluminum Base Plate 01

Base material: aluminum base

Copper thick: 1/2 ounce

Dipping: 0.3-0.5mm

Imitation: Wiring, V-CUT, Cutting

Service: One -stop service

Material: aluminum single -earthplate

Surface: operating system

Basic Information

Origin; Origin: China

Certification: CE, ROHS, UL

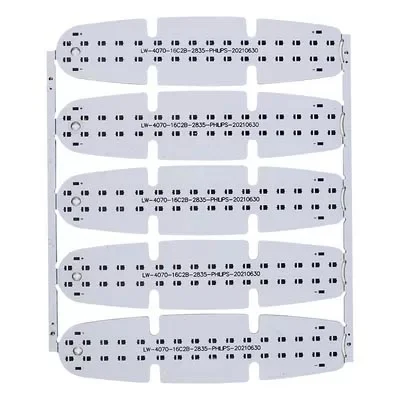

Model: Aluminum PCB circuit board 01

Base material :: aluminum base

Copper thick: 0.5 ounces, 1.0 ounces, 2 ounces, 3 ounces

Board thick: 0.2mm -4mm

minute. The size of the hole: 0.25mm (10mils)

minute. Width: 0.25mm (10mils)

V-CUT angle: 20, 25, 30, 45 degrees

Basic Information

Origin; Origin: China

Certification: CE, ROHS, UL

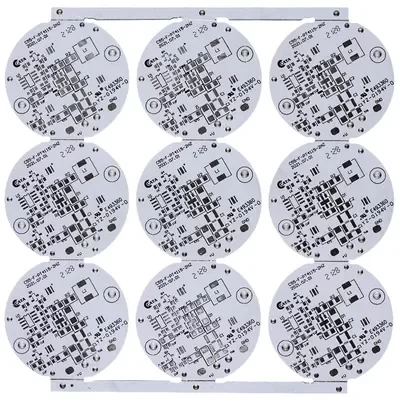

Model: 12W LED PCB board

minute. The size of the hole: 0.25mm

Silk print: white, black, yellow

Electrical test: fixture/flying needle

Kong tolerance: PTH: ± 0.075, NTPH: ± 0.05

Service: One -stop service

Basic Information

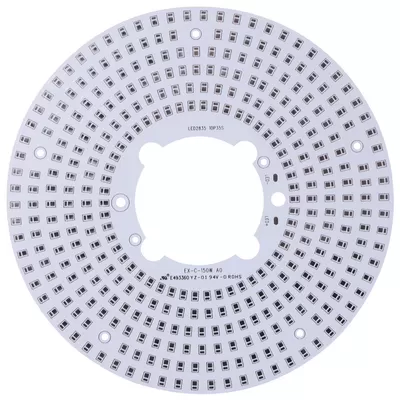

Origin; Origin: China

Certification: UL, CE, RoHS

Model: Electronic LED PCB 01

Base material: electronic product LED PCB

LED chip: 2830 5730 3535 5050 3030

Backbility: 94V0

Board size: customized

Surface treatment: HASL Leadless

Application: Light

Basic Information

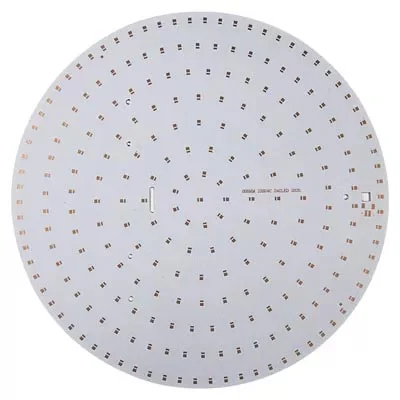

Origin; Origin: China

Certification: CE, ROHS, UL

Model: Aluminum Base Plate 01

Base material: aluminum base

Copper thick: 1/2 ounce

Board thick: 1.2mm

Size: Customized

Service: One -stop service

Basic Information

Origin; Origin: China

Certification: UL, CE, RoHS

Model: LED panel PCB board

Supplier Type: OEM/ODM

Test: fixture test fixture/flight test

Silk print: white, yellow, black

Test service: flying needle, 100% AOI test, 100% ET test

Street Light SMD 5730 LED Aluminum PCB

Place of Origin; Place of Origin: China

Certification: UL, CE, ROHS

Model: PCB 05

Layers: 1-2 layers

Tests: Fixture Test Fixture/Flight Test

Certificate: ISO9001:2008, ROHS, UL

Finished plate thickness: 0.2-7.0mm

Silkscreen: white, yellow, black

Testing service: Flying probe, 100% AOI testing, 100% ET testing

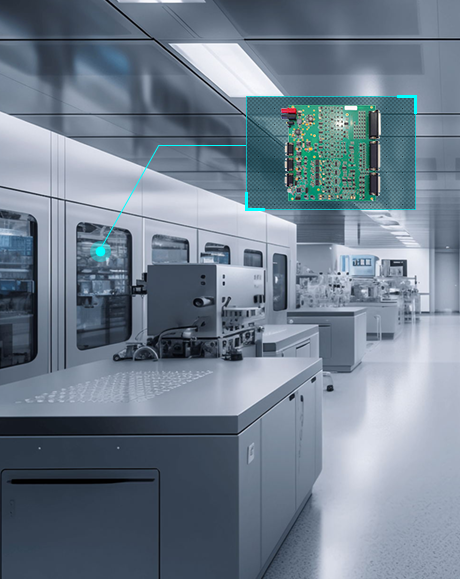

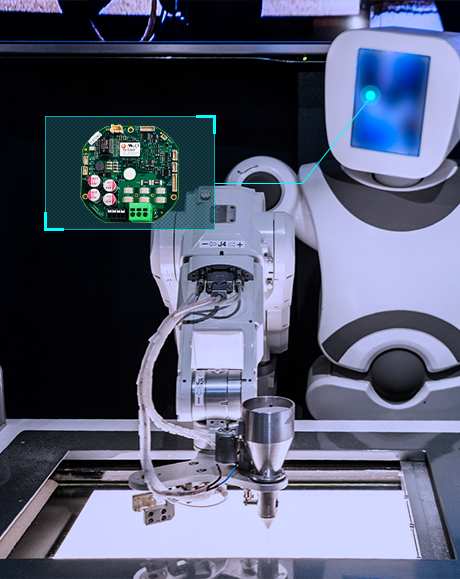

- PCB Manufacturing Equipment

- Aluminum PCB Capability

PCB Drilling machine

PCB pattern plating line

PCB solder mask expose machine

PCB pattern expose machine

Strip film etching line

Solder mask screen silk print machine

Solder mask scrubbing line

PCB Flying Probe Test (FPT)

Fully automatic exposure machine

| Aluminum PCB Capability | ||

| Aluminum PCB Feature | Parameter (in) | Parameter (mm) |

| Layers | 1 – 6 | 1 – 6 |

| Max Board Size | 24” x 40” | 609.6 x 1016mm |

| Min Board Thickness – 1-2 (layers) | 16mil | 0.4mm |

| Min Board Thickness – 4 (layers) | 20mil | 0.5mm |

| Min Board Thickness – 6 (layers) | 24mil | 0.6mm |

| Board Thickness Range | 16 – 157mil | 0.4 – 4mm |

| Max Copper Thickness | 5oz | 175um |

| Min Line Width / Space | 4mil / 4mil | 0.1 / 0.1mm |

| Min Hole Size | 20mil | 0.5mm |

| PTH Dia. Tolerance | ±2mil | ±0.05mm |

| NPTH Dia. Tolerance | ±1mil | ±0.025mm |

| Hole Position Deviation | ±4mil | ±0.1mm |

| Outline Tolerance | ±4mil | ±0.1mm |

| S/M Pitch | 3mil | 0.08mm |

| Aspect Ratio | 6:01 | 6:01 |

| Thermal Shock | 5 x 10Sec @288 | 5 x 10Sec @288 |

| Warp & Twist | <= 0.75% | <= 0.75% |

| Flammability | 94V-0 | 94V-0 |

Aluminum PCBs are usually stored in a dark, dry environment. Most aluminum PCBs are susceptible to moisture, yellowing and blackening. It should generally be used within 48 hours of opening the vacuum pack.

Circuit copper layer, insulating layer, metal substrate.

Environmental protection, fast heat dissipation, good durability, lightweight

Among all metal core PCBs, aluminum core PCBs are the most common type. The base material consists of an aluminium core and standard FR4. It features thermal cladding to efficiently dissipate heat while cooling components and improving the overall performance of the product.