Nowadays, the FPC flat cable has a wide range of uses, but many friends often understand it and the FFC flat cable as the same meaning. The following is a short compilation to explain in detail what the FPC flat cable and the FFC flat cable mean and what are their differences.

What is FPC flat cable

1. What is FPC flat cable

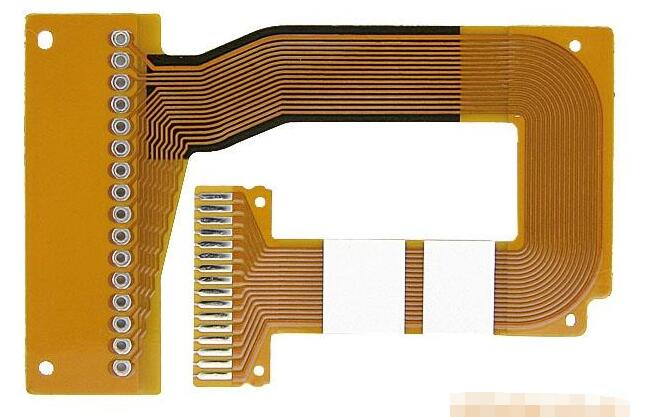

FPC flat cable is a set of connecting lines that can be bent to a certain extent. FPC can be divided into many types according to functions, such as FPC antenna, FPC touch screen, FPC capacitive screen, etc. FPC flat cable is one of them. The function of FPC flat cable is to connect two related parts or products. Now, many products use flat cable. Because of its flexibility, FPC flat cable has been used in many products such as printers, mobile phones, laptops, etc.

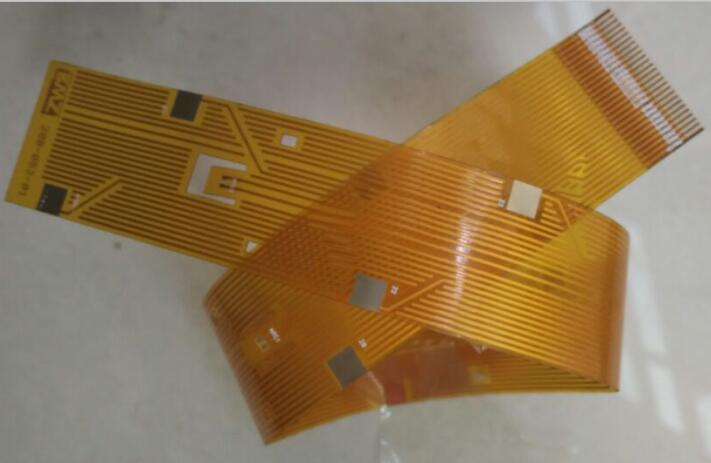

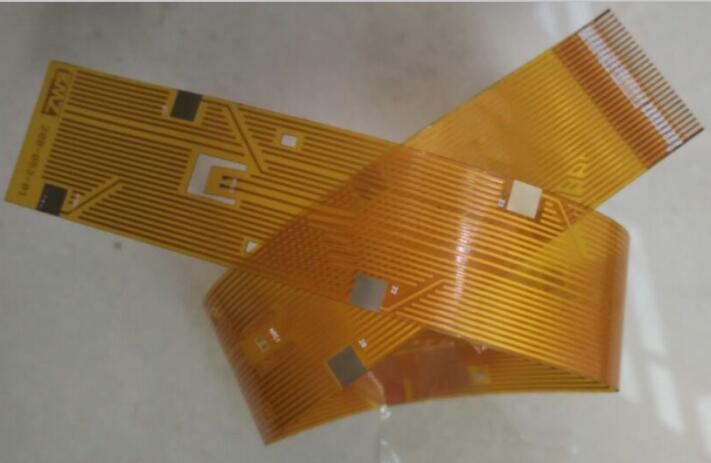

2. What is FFC flat cable

FFC flat cable, also known as flexible flat cable, can arbitrarily select the number and distance of wires, making the connection more convenient, greatly reducing the volume of electronic products, reducing production costs, and increasing production power. It is most suitable for use as data transmission cable between mobile parts and motherboards, between PCB boards and PCB boards, and in small electrical equipment. General standards include 0.5mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 1.5mm, 2.0mm, 2.54mm and other flexible cables with various distances.

3. Difference between FFC flat cable and FPC flat cable

FPC is a flexible printed circuit. In terms of manufacturing, the circuit composition methods are different:

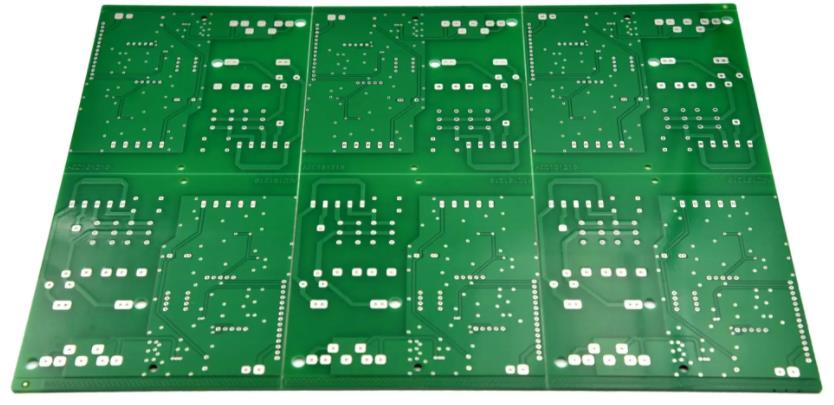

1. FPC uses chemical etching method to process FCCL (flexible copper clad foil) to obtain flexible circuit boards with different single-sided, double-sided and multi-layer structures.

2. FFC uses flat copper foil sandwiched between two layers of insulating foil film. The product is simple and thick.

4. Advantages and disadvantages of FPC flat cable

advantage:

The volume and weight of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products. In addition, it can also be arranged arbitrarily according to the spatial layout requirements, and move and expand freely in three-dimensional space, so as to achieve the integration of component assembly and wire connection.

Disadvantages:

In the process of producing products, cost should be the most important consideration. Because the soft FPC is designed and manufactured for special applications, the initial cost of circuit design, wiring and photographic plate is high. Unless there is a special need to apply soft FPC, it is better not to use it in a small amount of applications. In addition, since a lot of efforts have been invested, the later maintenance is also essential, so soldering and rework require trained personnel.

5. Advantages and disadvantages of FFC flat cable

advantage:

1) With small volume and light weight, the flat panel was originally designed to replace the larger harness wire. In the current cutting edge electronic device assembly board, flat cable is usually the only solution to meet the requirements of miniaturization and mobility. Flat wire (sometimes called flexible printed circuit) is to etch copper circuit or printed polymer thick film circuit on polymer substrate.

For thin and light devices with compact and complex structures, its design solutions include from single-sided conductive lines to complex multi-layer three-dimensional assembly. The total weight and volume of the flat wires are 70% less than that of the traditional round wire harness method [%]. The flat cable can also be strengthened by using reinforcement materials or lining plates to obtain additional mechanical stability.

2) It can be moved, bent and twisted without damaging the wires, and can comply with different shapes and special package sizes. The only limitation is volume space. As it can withstand millions of times of dynamic bending, the flat cable can be well applied to the internal connection system with continuous or regular movement, and become a part of the function of the final product.

Solder joints on rigid PCBs are subject to thermal mechanical stress and will fail after hundreds of cycles. Andy, product manager of EECX Electronic, said: "It requires electrical signal/power supply to move, and some products with smaller shape factor/package size benefit from flat cable."

3) It has excellent electrical property, dielectric property and heat resistance. Evan, general manager of EECX Electronic, said: "The low dielectric constant allows the rapid transmission of electrical signals; the good thermal performance makes the element easy to cool down; the higher glass transition temperature or melting point makes the element work well at a higher temperature."

4) It has higher assembly reliability and quality. The flat cable reduces the hardware required for internal connection, such as solder joints, trunk lines, backplane lines and cables commonly used in traditional electronic packaging, so that the flat cable can provide higher assembly reliability and quality.

Because the traditional internal hardware composed of complex multiple systems is easy to have high component dislocation rate during assembly. Joan, the marketing manager of EECX Electronic, said: "The ffc flat cable has low stiffness and small volume, which is precisely because the flat cable plate components are small, so the materials used are less." With the advent of quality engineering, a thin PCB system was designed to be assembled in only one way, thus eliminating many human errors usually associated with independent cabling engineering.