All products follow the same basic life cycle at the abstract level. First, they start with a spark of an idea, then turn it into a set of product requirements. In turn, these requirements drive the design process. The final design is then implemented into a tangible product and then deployed to the market. Often, products evolve over time in the marketplace in response to changes in consumer trends, competitive pressures, or regulatory requirements. But, of course, not all ideas make it to market, so this life cycle can often be shortened or go through a few intermediate iterations before proceeding.

Confusingly, the term product lifecycle is often used in the field of marketing to cover the period during which a product is sold. This dependent life cycle consists of bringing a product to market and growing sales until it reaches maturity and market saturation. A decline in sales before retirement, replacement, or rework indicates the end of the marketing life cycle. This represents a subset of the product's overall lifecycle.

Product lifecycle management

Product Lifecycle management (PLM) is simply the process of effectively and efficiently managing the phases of the product lifecycle to maximize the chances of success, achieving business goals, and realizing financial returns. These goals are achieved by managing business processes and data throughout the lifecycle.

PLM covers all the steps in a product's life cycle, from initial design and development, through manufacturing, to marketing and service support, to final disposal.

To be effective, a PLM must bring together all the parties involved in the production of a product to simplify the process and maximize efficiency. The goal of PLM is to produce the right product, get it to market at the right time, and maximize profits by generating consumer demand and outperforming competitors.

To be truly effective, PLM must be integrated with the other building blocks of an integrated business management system. Namely, enterprise resource planning (ERP), supply chain management (SCM), and customer Relationship management (CRM).

The benefits of a good PLM are to anticipate and avoid problems, schedule, resolve problems, and respond to events, while minimizing costs over the life of the product.

concept

The concept phase is the phase in which an initial idea is turned into a viable concept for a product. It is a product that is easy to create, has a market demand that is sufficient to meet sales targets, and will provide enough return on investment over its life cycle to be an attractive proposition.

Feasibility will boil down to whether the technology exists to implement the idea and whether the business has the resources to design and develop the idea into a product.

Marketability will boil down to whether enough customers are willing to buy the product at the target price. This will be influenced by the demographics of the target audience, the existing competition, and the impact of competitor products that are also in development.

The return on investment assessment balances the projected sales revenue against development, operations and support costs over the life of the product.

The concept phase aims to create a set of product requirements that precisely define what the product should and shouldn't do. The PLM process should support the collation and management of these product requirements into a single source of product design facts arising from them.

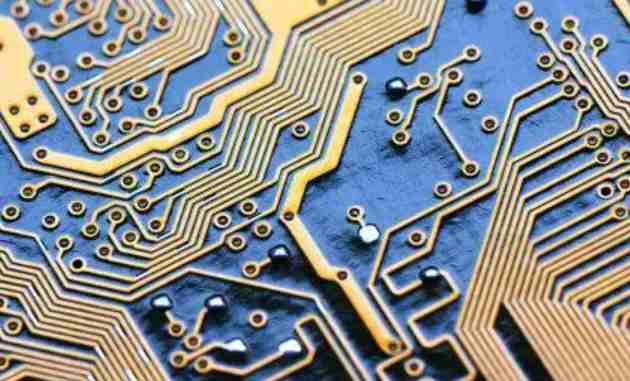

design

The design phase translates the product requirements into a blueprint for developing the product, including any prototyping and proof-of-concept activities to validate the requirements and provide project risk reduction measures.

Typically, the design phase is an iterative process that uses feedback from each cycle to improve and enhance the design until it meets stakeholder satisfaction. For the electronics industry, computer-aided design tools and simulations support the design process. The PLM process should support the creation, sharing, and management of design data generated during this phase. This data includes documented design decisions to demonstrate compliance with product requirements for component data sheets to support the development process -- design schematics and bills of materials to support manufacturing and supply chain processes. PLMS should support the collation and management of this product design data into a single authentic source from which products can be manufactured.

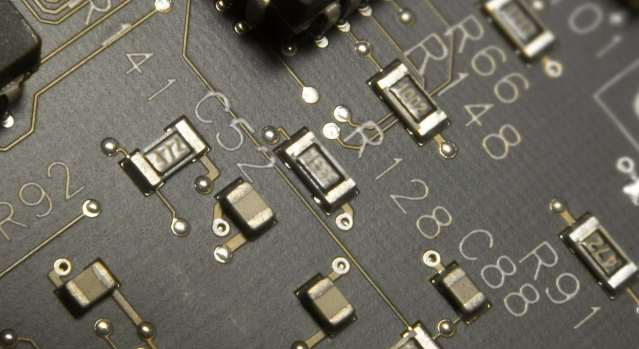

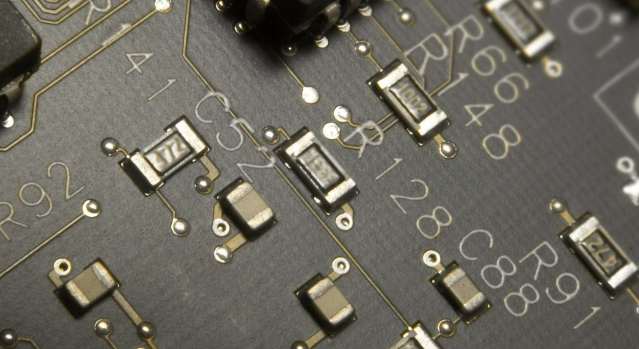

realization

The product realization phase involves transforming a finished design into a production-ready product that can be reliably and repeatably manufactured on a large scale.

The final product is then brought to market, the development process is over, and the sales and marketing process takes over the release, distribution, and promotion of the product.

The PLM process should support the collation and management of product information into a single authentic source from which product documentation, such as user manuals or marketing materials, can be generated.