Special knowledge of PCBA circuit board three proofing coating

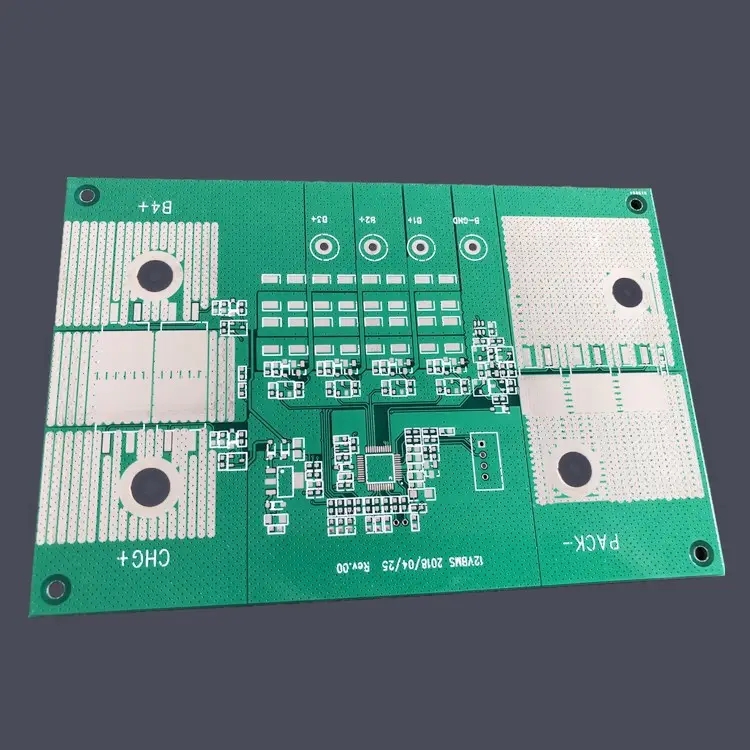

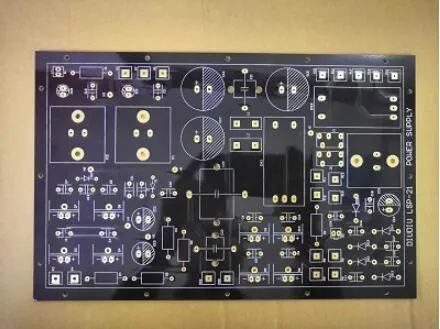

PCBA three proof paint is used to protect oil, waterproof glue, insulating paint, prevent moisture, mildew, dust and insulation, so it is called three proof paint. It is mainly used at the rear end of the assembly. After the SMT chip is processed and tested, the product surface is treated with three proof treatment, including immersion, brushing, spraying, selective coating, etc. This is what we often call the "three proofing" coating process for PCBA circuit boards.

The painting thickness is generally 0.15mm to 0.35mm. The painting shall be carried out at a temperature of not less than 15 ℃ and a relative humidity of less than 70%. It plays an important role in protecting products, especially in some environments where the temperature and humidity are relatively poor. The application of three proofing paint is superior, which can definitely make the storage time of circuit boards longer, improve the reliability of electronic equipment, reduce the warranty cost, and prevent external corrosion and pollution of products. Spraying is the most common coating method in the industry.

1. Clean up the dust, moisture and rosin on the product surface, keep it clean and dry the board, so that the three proofing paint can be well pasted on the circuit board surface.

2. The brushing area shall be even to ensure that all components and pads are covered. Baking condition: 65 ° C, 15-35 minutes, after taking it out of the oven, the coating effect is better when it is hot.

3. When painting, the pcba board should be placed on a flat desktop. After painting, there should be no dew or exposed parts. The thickness of 0.1-0.3mm is the most appropriate.

4. Place the coating on the shelf to cure it (heating can also accelerate the curing of the coating).

5. When painting the three proofing paint, it should be noted that all high-power cooling surfaces or radiator elements, power resistors, power diodes, cement resistors, etc. cannot be painted with the three proofing paint. They should be covered for protection during painting. The screw holes on the plate cannot be painted with the three proofing paint.

6. If you want a thicker coating, you can apply two thinner layers of coating for superposition (the second layer shall be brushed after the first layer is cured).

7. The work of three proofing paint shall be carried out in a separate closed room with good ventilation facilities. Wear protective equipment such as masks and gloves during operation to protect the body from injury.

PCB manufacturers, PCB designers and PCBA manufacturers will explain to you the knowledge that should be specially known about the three proofing coating of PCBA circuit boards.