Electronic editor explains the advantages of double-sided SMT mounting

A customer will mention a double-sided SMT mounting when communicating about SMT mounting processing. What is double-sided SMT mounting? What are the advantages of double-sided SMT mounting?

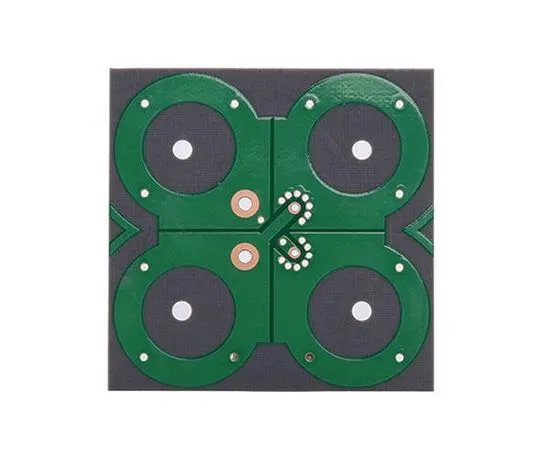

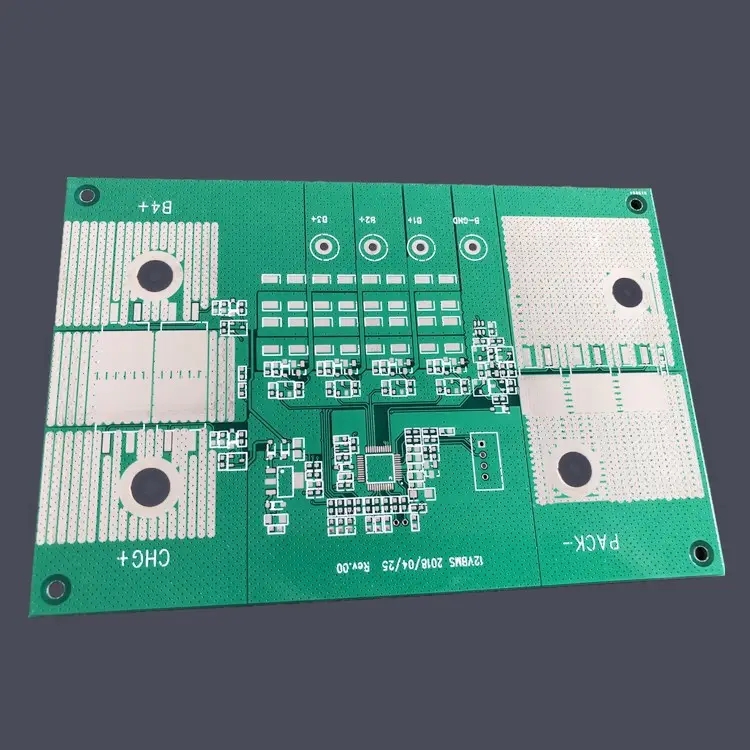

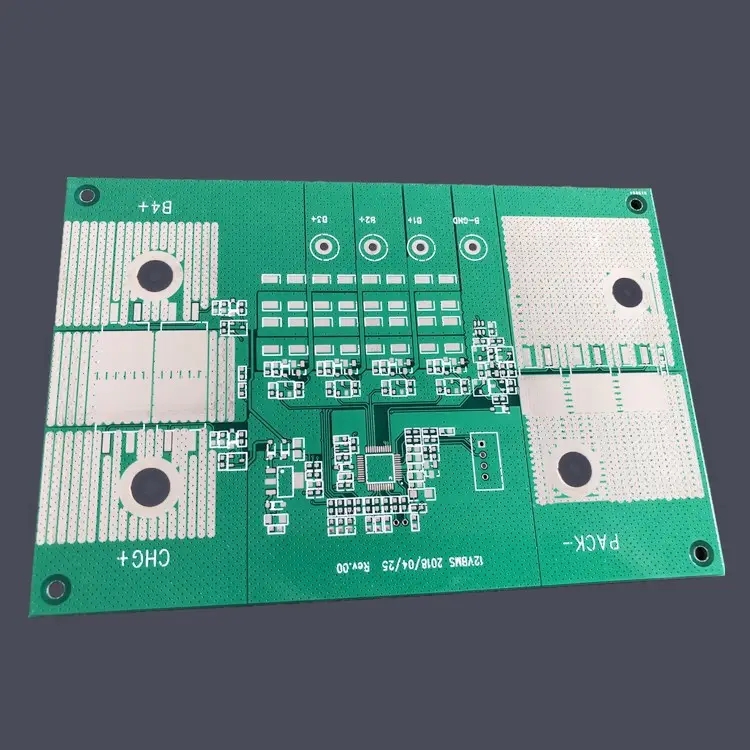

In order to ensure the aesthetics and functionality of PCB boards, PCB design engineers will adopt double-sided mounting. IC components are arranged on side A and chip mounted components are arranged on side B. Make full use of PCB board space to achieve smaller PCB board area.

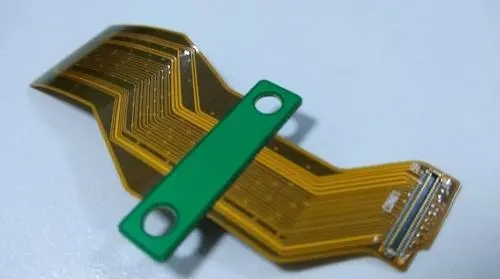

Choosing an appropriate assembly method according to the specific requirements of the assembled products and the conditions of the assembled equipment is the basis for efficient and low-cost assembly production, and is also the main content of SMT chip processing process design. The so-called surface assembly technology refers to the assembly technology of electronic components with certain functions by placing the components with sheet structure or small components suitable for surface assembly on the surface of the printed circuit board according to the requirements of the circuit and assembling them with reflow welding or wave soldering and other welding processes.

How to find the manufacturer of double-sided SMT patch

If you need double-sided SMT patch, you need to find a professional SMT patch factory for patch processing. Here you need to see the production equipment and factory scale owned by the other party.

What are the differences between the two mounting methods of double-sided mixed mounting

The following two methods are available for double side mixed loading. The former method is not recommended for PCBA assembly with three times of heating, which has low efficiency, and wave soldering with red glue process has low qualification rate. The second method is applicable to the situation where there are many double-sided SMD components and few THT components, so manual welding is recommended. If there are many THT components, wave soldering is recommended.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the advantages of double-sided SMT mounting.