What are the most important procedures and links for customers to evaluate the SMT process?

From the perspective of technology and quality, as long as we select the most important links in the whole SMT process, we can roughly see whether a SMT factory is able to produce boards that meet our requirements. The following editor tries to list some relatively important items in SMT production control for your reference: 1. Can the quality of solder paste printing be consistent. 2. How to test and judge whether the furnace temperature meets the requirements during reflow. 3. How to avoid wrong parts. 4. How to avoid hand-operated parts

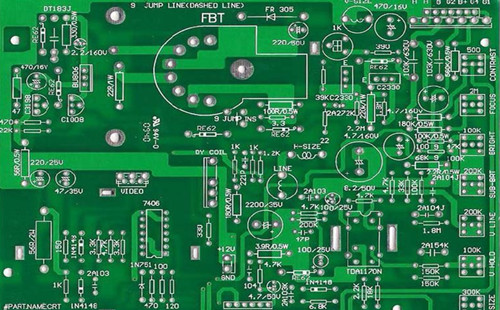

From the perspective of technology and quality, as long as we select the most important links in the whole SMT process, we can roughly see whether a SMT factory is able to produce boards that meet our requirements.

The following editor tries to list some items that he thinks are relatively important in SMT production control for your reference:

1. Whether the solder paste printing quality can maintain consistency.

2. How to test and judge whether the furnace temperature meets the requirements during reflow.

3. How to avoid wrong parts.

4. How to avoid hand hanging parts.

5. Is there the ability to calculate and modify the thickness and opening size of steel plate to meet the actual needs.

6. Whether there are enough equipment or instruments to analyze the defective welding products.

Among them, the quality control of solder paste printing is the most important, because if the solder paste cannot be printed well, it is useless to make the following patch more accurate and the temperature of the reflow furnace better adjusted.

Solder paste

In terms of the overall process capability of SMT today, the solder paste printing capability is the worst. Because more solder paste printing or less printing or printing offset are related to the quality of solder later, it is most necessary to be specially controlled. The accuracy of other mounters has already exceeded the required level, so there is nothing to say. Unless the X-Y position program was not written at the beginning, the temperature curve of the reflow furnace has already been determined. As long as we know that the melting tin temperature and enough heat may cause damage to materials, there is no need to adjust anything else.

How to evaluate and ensure the consistency of solder paste printing quality?

Solder paste printing can basically be divided into two key points:

1、 Ability of solder paste quality control

Solder Paste Control 03 Solder Paste Control 02 Besides the brand, the freshness of solder paste is another good and bad thing. It is recommended to use a reputable company for the brand of solder paste, which will be more safe. As for the freshness of solder paste, it is necessary to check the time tracking of solder paste after deicing, opening cans, and stirring. Each company must have internal rules to specify how long the solder paste should be used up when exposed to the air, so as to avoid excessive oxidation of solder paste, which will lead to poor tin eating during subsequent reflow. In addition, the control of solder paste applied to steel plate is the key point. As long as this is well controlled, there should be no other problems.

Solder Paste Control01 Therefore, the key to check the solder paste life is to look at the lunch time or dinner time. How will the solder paste that has been coated on the steel plate be handled? How to time the solder paste when the line stops? How to control the solder paste that has been applied to the original steel plate when changing lines and steel plates?

Another project needs to be asked in detail. If the SMT of the factory is not in a 24-hour shift, from the shutdown to the start of production, how is the first batch of solder paste de icing and re warming treated? It is unlikely to stop the whole SMT line until the solder paste warms up. Generally, the solder paste warms up for more than 4 hours. If so, it means that the production line will not produce for 4 hours. Therefore, employees will be arranged to come to work 4 hours earlier to warm up the solder paste, or will it be warmed up the day before. If the solder paste warms up more than one day earlier, the activity of the solder paste will decrease, Generally speaking, if the solder paste is warmed up for more than 12 hours, it will be scrapped.

As for why solder paste should be refrigerated at low temperature? This is to maintain the activity of solder paste; Why should it be warmed up before use? This is to keep the solder paste consistent with the room temperature, so as not to produce water droplets condensed on the solder paste and spatter during high-temperature reflow.

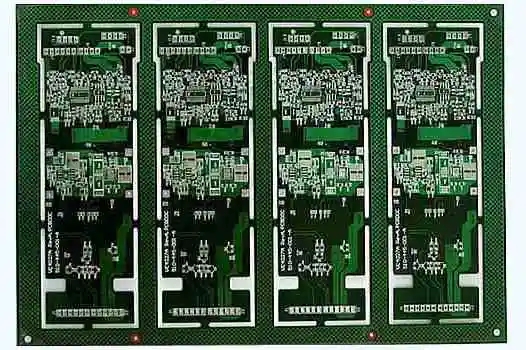

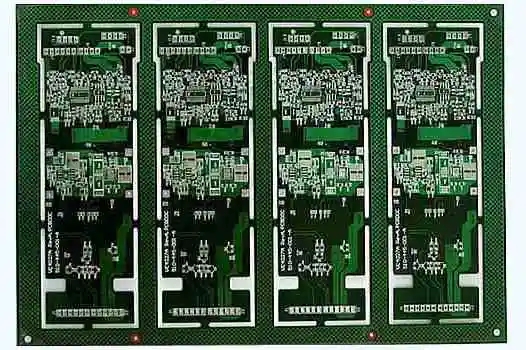

2、 Solder paste printing capability

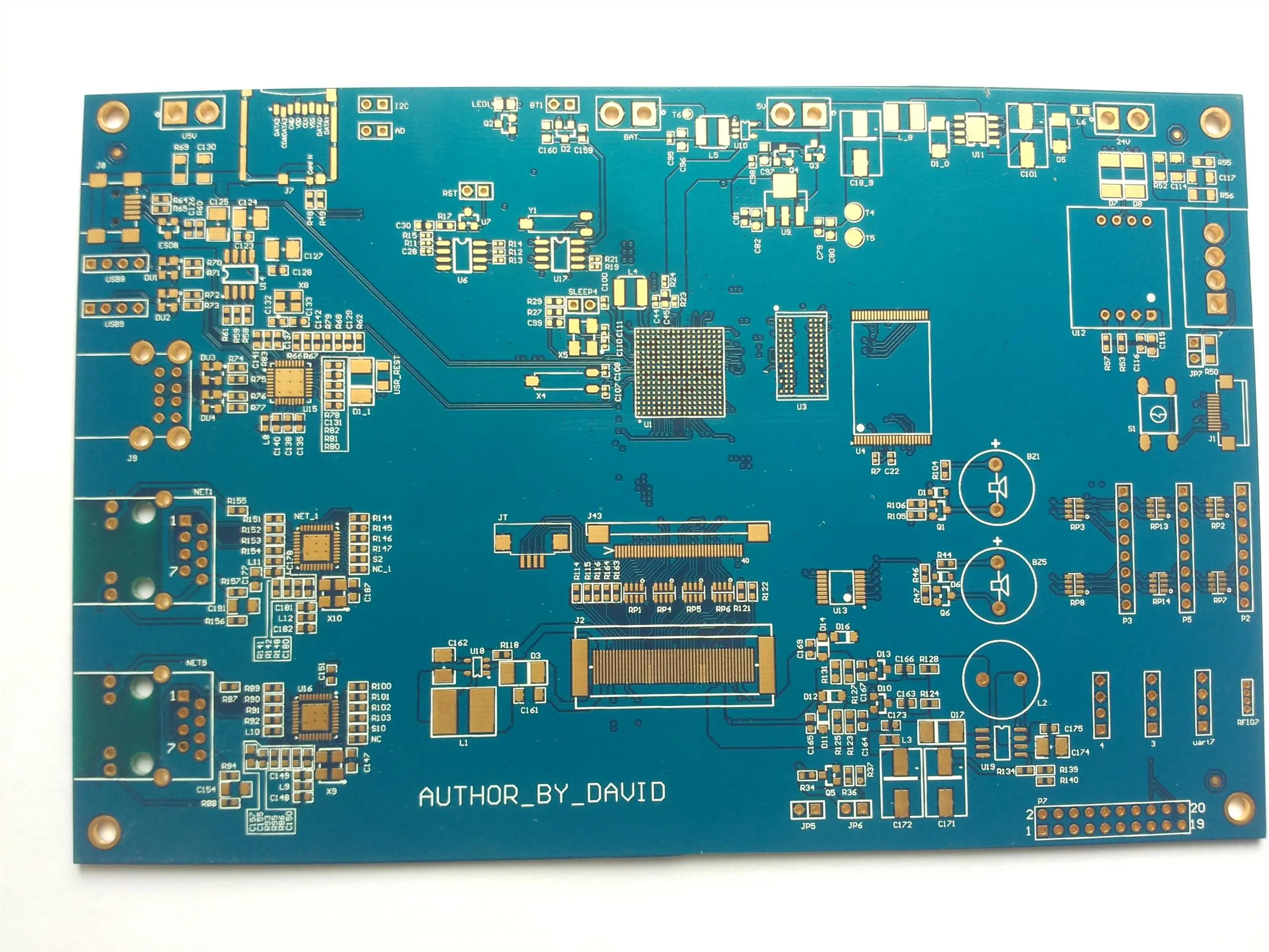

SMT solder paste printing As for the evaluation of solder paste printing ability, it can be required to take the board with fine spacing (0.4 mm or 0.5 mm) BGA on the PCB for solder paste printing test, so that the same PCB can pass repeated solder paste printing for many times (5~10 times is appropriate, if 25 times can be done, of course, it will be the last, but it takes too much time), and after each printing, the printing results should be observed under the microscope (it is recommended to take photos at four corners for storage), Check whether there is tin bonding or whether the printing offset exceeds 1/3 of the solder balls of the pad/pad to judge the printing ability.

If the production line has SPI (Solder Paste Inspector), it is recommended to measure the solder paste printing volume (volume), and then calculate the variance. Cpk should be of little significance because the tolerance is difficult to define.

In addition, the wiping and cleaning of the steel plate is also one of the factors that affect the quality of solder paste printing. Because the solder paste will leak tin (the solder paste will stick to the back of the steel plate) after a long time of printing, which is a major culprit for tin connection, it is important to wipe the steel plate with a dust-free cloth every other time (several times of PCB printing), and how many times the steel plate printing is cleaned with ultrasonic wave to avoid the problem of hole gambling.