Several points to note in the process of SMT patch processing

SMT or surface mount technology is one of the most commonly used technologies in modern electronics production. It has been widely used in various fields, including automotive electronics, consumer electronics, industrial automation and so on. In the SMT patch processing process, there are some key considerations that we need to pay special attention to.

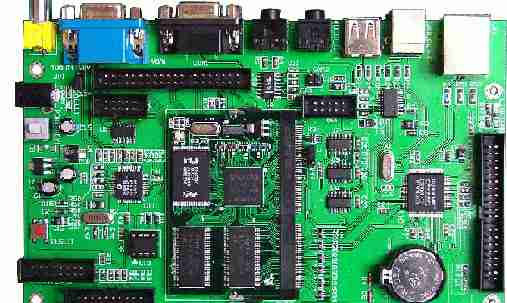

First of all, for each step of SMT patch processing, we need to ensure that the operator has been professionally trained and mastered the correct operating methods and processes. In the product assembly, welding and testing links, each link needs professional technology and strict operation process. Only in this way can we guarantee the quality of the patch products.Secondly, we need to pay attention to the materials and requirements of SMT patches. The materials required for SMT patch processing are very important, such as the printed circuit board (PCB), components, solder, etc., that the patch needs to use. For different types of patches, we need to choose appropriate materials, and process and test according to requirements.

Third, patch processing requires very strict quality inspection procedures. We need to conduct a comprehensive inspection of each batch of products to ensure that the performance and quality of the products meet the requirements. In SMT chip processing, we need to fully monitor and manage the welding process, assembly process, testing process and other aspects. Only in this way can we guarantee the stability and reliability of our products.

In addition, in the SMT patch processing process, we also need to pay attention to details. For example, when collaging components, it is necessary to carefully check whether the label and position of the components are accurate. In the welding process, it is necessary to ensure the quality of welding, but also need to pay attention to the rationality of welding parameters. In addition, we also need to ensure the accuracy of various materials and documents of the patch to ensure that the final quality of the product meets the requirements.

In short, SMT patch processing is a very complex and meticulous process. In the entire process of processing, we need to pay attention to quality, materials and quality inspection, pay special attention to every detail, to ensure that products reach the highest level of quality standards. Only in this way can we meet the needs of the market and contribute to the development of the electronics industry.

In the PCBA process, quality control is a very important link. If we can effectively carry out quality control, then we can ensure that the final product we produce is of high quality, which is very important for our customers and consumers. In this article, we will explore how to do quality control in PCBA processing. How to do quality control in PCBA processing

First, we need to understand what PCBA processing is. PCBA is the abbreviation of Printed Circuit Board Assembly, that is, printed circuit board assembly. It is a very important part of our electronic products, including the assembly and welding of circuit boards. The process of PCBA processing is very complex and requires a high degree of precision and technical requirements. Therefore, we need very strict quality control during PCBA processing.1. Selection of materials

In the PCBA process, we need to choose high-quality materials. These materials need to meet our equipment requirements to ensure that the quality of the products we manufacture is at a high level. At the same time, we also need to choose reliable material suppliers to ensure that we can obtain high-quality materials.2. Process controlIn PCBA machining process, process control is very important. We need to make sure that every step is carried out according to the standard and that nothing goes wrong in the production process. This is very important to ensure that the quality of our products is at a high level.

3. Equipment maintenance PCBA processing requires the use of a large number of equipment and machines, so the maintenance of equipment and machines is also very important. We need to regularly inspect and maintain our equipment and machinery to ensure that they are functioning in optimum condition. This helps to ensure that our products meet the requirements of our customers.

4. Quality testing Quality testing is one of the important means to ensure that the quality of the products we produce is high. We need to conduct quality inspection at each step and a final inspection of the entire product before the final product leaves the factory. This helps us identify any potential problems and resolve them in a timely manner.5. Staff training

https://www.kingfordpcb.com/yuan.php.

https://www.kingfordpcb.com/yuan.php.

In the process of PCBA processing, the above aspects are very important. We need to pay attention to these aspects to ensure that the product we end up producing is of a high level of quality. At the same time, we also need to constantly sum up experience in actual production and constantly improve the quality control process.