I. Technical requirements of SMT proofing

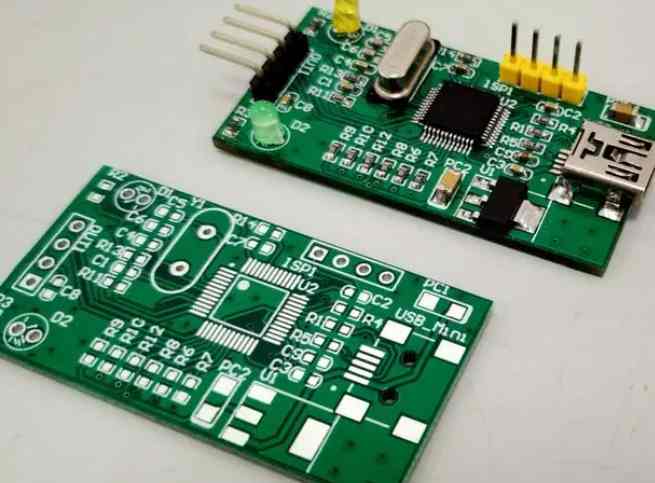

The technical requirements of SMT proofing refer to the installation and proofing technology of electronic components on the printed circuit board, which is the key technology of accurate installation of electronic components on the printed circuit board. The technical requirements of SMT proofing include three aspects:

1) Installation and positioning technology: it refers to the positioning technology of electronic components installed on the printed circuit board. During installation and positioning, the electronic components are required to be accurately positioned through the positioner to ensure the installation accuracy of the components.

2) Welding technology: It refers to the welding technology in which electronic components are installed on the printed circuit board. In the process of installation, it is required to weld the surface of electronic components and printed circuit board through welding materials to ensure the installation accuracy of components.

3) Patch technology: it refers to the patch technology in which electronic components are installed on the printed circuit board. In the process of installation, it is required to patch the surface of electronic components and printed circuit board through the patch materials to ensure the installation accuracy of components.

4) Pad precision technology: it refers to the precision technology of the welding pad of electronic components. In the process of installation, high precision requirements are required for the welding pad of electronic components to ensure the installation accuracy of components.

5) Optical detection technology: it refers to the optical detection technology of electronic components installed on the PCB board. In the process of installation, the installation accuracy of electronic components is required to be tested by testing instruments to ensure the installation accuracy of components.

6) Quality control technology: it refers to the quality control technology of electronic components installed on the printed circuit board. In the process of installation, quality control is required for the proofing technology to ensure the installation accuracy of components.

2. SMT proofing process

SMT proofing process refers to the installation and proofing process of electronic components on the printed circuit board, which is the key process of installing electronic components on the printed circuit board. SMT proofing process includes three steps:

1) Positioning welding link: It refers to the positioning welding link in which electronic components are installed on the printed circuit board. In the positioning welding link, the electronic components are required to be accurately positioned through the positioner, and then the surface of the electronic components and the printed circuit board is welded to ensure the installation accuracy of the components.

2) Patch link: It refers to the patch link where electronic components are installed on the printed circuit board. In the patch link, it is required to patch the surface of electronic components and printed circuit board through the patch material to ensure the installation accuracy of components.

3) Detection link: it refers to the detection link where electronic components are installed on the printed circuit board. In the detection link, the installation accuracy of electronic components is required to be tested by testing instruments to ensure the installation accuracy of components.

Iii. Quality control of SMT proofing

SMT proofing quality control refers to the installation of electronic components on printed circuit board proofing quality control, it is the key quality control of electronic components installed on printed circuit board. SMT proofing quality control requirements are as follows:

1) Precision control of the installation position of electronic components: the installation accuracy of electronic components must meet the design requirements and shall not be offset or tilted to ensure the installation accuracy of components.

2) Precision control of welding technology: It is required that the welding technology of electronic components must meet the design requirements, and no missed welding or multiple welding is allowed to ensure the installation accuracy of components.

3) Precision control of the pad: the precision of the pad of electronic components must meet the design requirements and must not be deformed or damaged to ensure the installation accuracy of the components.

4) Precision control of quality testing: The quality testing of electronic components must meet the design requirements and shall not be missed to ensure the installation accuracy of components.

5) Process stability control: It is required that the process stability of electronic components must meet the design requirements without quality jitter, so as to ensure the installation accuracy of components.

6) Quality tracking control: It is required that the quality tracking of electronic components must meet the design requirements without quality fluctuation, so as to ensure the installation accuracy of components.

2.Where can smt processing be applied? What are the advantages of SMT processing?

First, SMT processing concept

SMT processing is the abbreviation of Surface Mount Technology, which refers to a technology of welding parts to the surface of printed circuit board, also known as surface mount technology, is one of the most important technologies in modern electronics industry.

2. Advantages of SMT processing

(1)SMT processing can reduce the volume of printed circuit boards, improve the density of components, and reduce the volume of printed circuit boards, so as to achieve miniaturization and lightweight effect;

(2)SMT processing can improve the reliability of electronic components, because the surface mounting technology can control the welding temperature, so as to ensure the reliability of electronic components;

(3)SMT processing can improve the repairability of products. Because SMT processing can improve the density of components, it can effectively reduce the number of repair and maintenance, so as to improve the repairability of products;

(4)SMT processing can speed up the productivity. Because the surface mounting technology can control the welding temperature and welding time, it can effectively improve the productivity.

Three, the application of SMT processing

(1)SMT processing can be applied to the welding of electronic components, especially under the requirements of miniaturization and lightweight of electronic components, SMT processing can effectively improve the density of components, so as to achieve miniaturization and lightweight effect;

(2)SMT processing can also be applied to mechatronics manufacturing, SMT processing can effectively improve the reliability and repairability of mechatronics products, so as to improve the reliability and repairability of products;

(3)SMT processing can also be used for the maintenance and repair of electronic components. SMT processing can greatly reduce the workload of maintenance and repair, thus speeding up the speed of maintenance and repair.