It can be said that the appearance quality of flux resistance is not only the embodiment of the technical level and management level of the enterprise, but also directly affects the order of the enterprise. Therefore, how to improve the appearance quality of the printed circuit board flux resistance has become an urgent problem to be solved in every PCB factory. Factors that affect the appearance quality of solder resistance

1, printing: photo solder resistance printing ink screen printing process, blade flatness, environmental purification, screen printing using barrier tape and ink printing pressure, printing preparation before the plate will affect the appearance of the quality, according to the actual production situation, the most important factors are the first three, the blade is not easy to produce plane marks on the solder resistance printing surface; The purification is easy to form a barrier on the garbage surface; When using improper tape, easy to make ink gelatinous solvent and surface particles.

Exposure: In the process of contact with welding ink, because the flux is not fully cured, the solder resistance layer and the solder paste together tend to produce impressions, which is the main reason affecting the appearance quality of the solder paste. Solder resistance ink through the development of general horizontal transfer type development, solder resistance is not fully cured, the developer drive wheel, press wheel and other easy to cause surface damage, roll marks, thus affecting the appearance of the solder resistance quality.

In addition, incorrect exposure energy can also affect the gloss of the solder choke, but this can be controlled with a wedge meter.

4, after curing: after curing solder temperature is not uniform, easy to lead to uneven solder paste color, when the temperature is too high will even cause local yellow, black, affect the beauty of the solder. When screen printing solder ink, due to the uneven screen printing surface, after a period of screen printing, the surface of the scraper will become uneven, so there will be scratches on the surface of the solder resistance layer.

Therefore, the operator must always pay attention to the surface condition, once found scraper marks, should immediately wipe the scraper to ensure smoothness. In order to obtain a printing board with good appearance quality, the cleanliness of the screen printing room plays a key role. All areas in contact with the printed circuit board (including workbench, screen frame, blotting paper, BLOCKOUTS tape) and the printed circuit board itself shall be dusted with drum dust. A clean room must be cleaned during turnaround. The cleaned room must be dressed in special clothing and hats, and in accordance with the regulations of the wind bath. At the same time, the protection of air purification around the factory is also crucial.

In the process of electronic commodity patch processing, there are many factors that will affect the quality of the commodity, such as patch processing equipment, process, technology and PCB board design, as we know, and the selection of patch processing data also has a great impact on the quality of the commodity. SMT processing is one of the rarest technologies in SMT processing industry. What achievements do we need to understand about such a process? How can we understand the technology of patch processing? How can we understand the elements of the existence of these results? Here are a few points for you:

Mounting of patch processing: Its role is to accurately install the external assembly components to the fixed position of PCB. The equipment used is the SMT machine, which is located in front of the screen printing machine in the SMT consumption line. Screen printing of patch processing: its function is to leak solder paste or patch glue onto the solder pad of PCB, to prepare for the welding of components. The equipment used is screen printing machine (screen printing machine), located at the front end of SMT consumption line. Solidification of patch processing: its role is to melt the patch glue, so that the external assembly components and PCB board solid bonding together. The equipment used is the curing furnace, which is located in front of the SMT machine in the SMT consumption line. The dispensing of patch processing: it is to drop the glue to the fixed position of PCB, and the second role is to fix the components to the PCB board. The equipment used is the dispensing machine, which is located at the front end of the SMT consumption line or in front of the detection equipment.

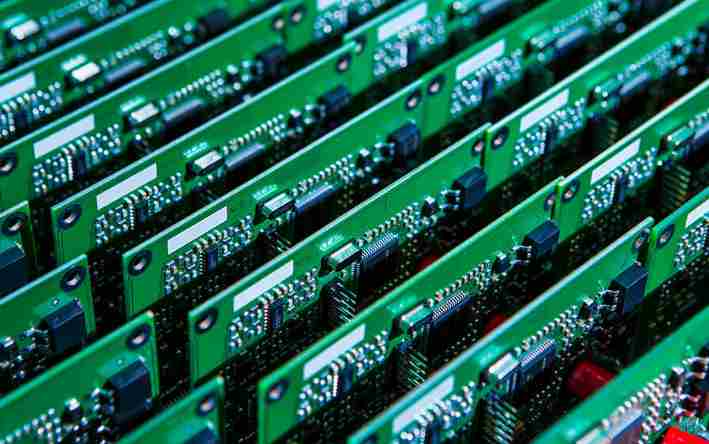

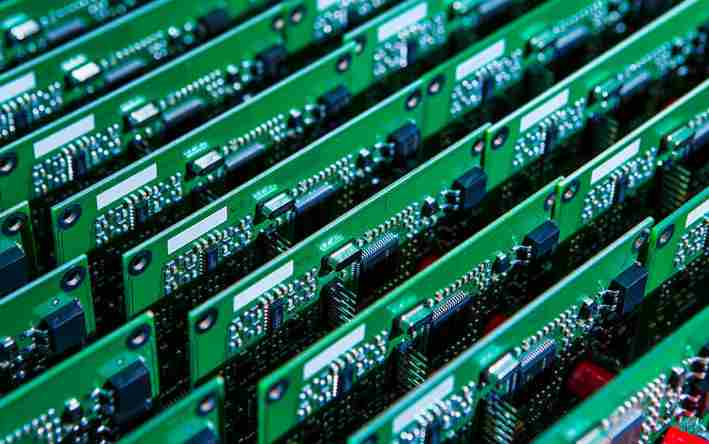

Shenzhen Baiqiancheng Electronics Co., Ltd. is a well-known professional SMT SMT processing enterprise in Guangdong province, the enterprise strength, the factory has a number of sets of export advanced SMT process equipment

Shenzhen Baiqiancheng Electronics Co., LTD., established in 2003 in Shenzhen, has been more than 10 years, has been working hard in the electronic products EMS manufacturing industry, focusing on providing customers at home and abroad with professional electronic products processing, patch processing, plug-in processing, OEM, ODM foundry services.