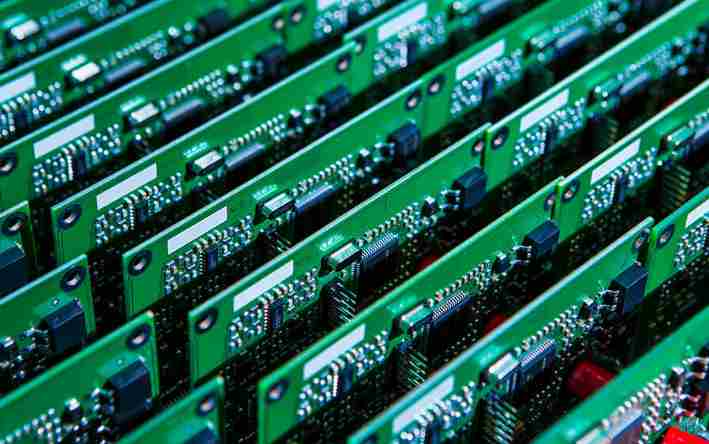

Printed circuit board as the core substrate of electronic products, its quality and reliability directly affect the quality and reliability of electronic products, so high reliability PCB has become the basic requirements of many electronic products. Today, let's take a look at the important characteristics of high reliability PCBS.

1, achieve 25μm hole wall copper thickness can enhance reliability, including improved Z-axis expansion resistance;

2, perfect circuit can ensure reliability and safety, high reliability PCB is generally no welding repair or repair repair, so that it can well avoid circuit board break and other risks.

3. Residue and solder accumulation on the circuit board will bring risks to the solderproof layer. Ionic residue will lead to corrosion and pollution risks on the welding surface, which may lead to reliability problems such as bad solder joints/electrical failures, and ultimately increase the probability of actual failures.

4, the surface treatment of the old circuit board will change metallofacies, there may be solder problems, and moisture intrusion may lead to stratification, inner layer and hole wall separation (open circuit) in the assembly process or actual use, so the high reliability of PCB will strictly control the service life of each kind of surface treatment.

5. Poor mechanical properties mean that the PCB circuit board cannot perform the expected performance under the assembled conditions. For example, high expansion performance will lead to delamination, circuit breaking and warping problems. Weakened electrical characteristics can lead to problems such as poor impedance performance. Therefore, high reliability PCB factories will use internationally renowned substrates, such as Shengyi, Kingboard, Liumao and other well-known brands. KINJI PCB factory is using these substrates to ensure high reliability of customers' PCB products.

6. Because the electrical performance may not meet the specified requirements, the output/performance of the same batch of components will be greatly different. The PCB factory with high reliability will strictly control the dielectric layer thickness to reduce the deviation of the expected value of electrical performance.

7, inferior ink can lead to adhesion, flux resistance and hardness problems. All of these problems can cause the solder shield to detach from the circuit board and eventually lead to corrosion of the copper circuit. Poor insulation characteristics can cause short circuits due to unexpected electrical connectivity/arcing. High reliability PCB factories will strictly define solder resistance materials to ensure compliance with IPC-SM-840ClassT requirements.

8, high reliability PCB will strictly define the shape, hole and other mechanical characteristics of tolerance, very good to improve the product size quality - improve the fit, shape and function.

9, thin solder resistance layer can lead to adhesion, flux resistance and hardness problems, high reliability PCB factory NCAB specified solder resistance layer thickness, although IPC has no relevant regulations.

10, high reliability PCB factory defines the appearance requirements and repair requirements, in the manufacturing process of careful care and carefully cast safety, avoid a variety of scratches, small damage, repair and repair.

11, the plug hole depth has a high requirement, the use of high-quality plug holes to reduce the risk of failure in the assembly process.