Note. Crystal oscillator

1. Usually only oscilloscope (crystal oscillator needs to be powered up) or frequency meter test, multimeter can not be measured, otherwise can only use the substitution method.

2. Common crystal vibration faults are :a. Internal leakage,b. Internal open circuit c. Deterioration frequency deviation d. Peripheral connected capacitance leakage. There is a leakage of electricity. Tester > The VI curve of theta should be measured.

3. During the whole board test, two judgment methods can be adopted :a. During the test, the relevant chips near and around the crystal oscillator do not pass. No other fault points were found except for the crystal oscillator.

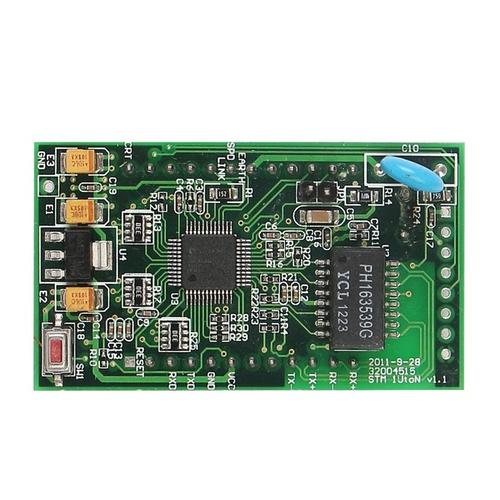

4. Crystal vibration is commonly divided into two types :a. two-pin and b. four-pin, of which the second pin is supplied with power, and it should not be short-circuited at will. 5. Distribution of fault phenomena 1. Incomplete statistics of circuit board fault location :1) chip damage 30%, 2) discrete component damage 30%,

3) 30% breakage of wiring (PCB coated copper wire); 4) 10% breakage or loss of program (with an upward trend).

2. From the above, when the circuit board is to be repaired and the program has problems, there is no good board, neither familiar with its wiring, can not find the original program. The board is unlikely to be repaired.

Compatible design:

Electromagnetic compatibility refers to the ability of electronic devices to work harmoniously and efficiently in various electromagnetic environments. The purpose is to make electronic equipment can not only suppress all kinds of external interference, so that electronic equipment can work normally in the specific electromagnetic environment, but also reduce the electromagnetic interference of electronic equipment itself to other electronic equipment.

1, choose a reasonable wire width because the impact of transient current on the printed line of PCB circuit board is mainly caused by the inductance component of the printed wire, so the inductance of the printed wire should be reduced as far as possible.

2, the use of the correct wiring strategy using equal wiring can reduce the inductance of the wire, but the mutual inductance and distributed capacitance between the wires increase, if the layout allows, it is best to use the zigzag mesh wiring structure, the specific approach is one side of the printed board transverse wiring, the other side longitudinal wiring, and then connected with metallized holes at the cross hole.

3, in order to inhibit the crosstalk between PCB circuit board wires, in the design of wiring should be as far as possible to avoid long distance equal wiring, as far as possible to open the distance between lines, signal line and ground and power line as far as possible do not cross. Crosstalk can be effectively suppressed by installing a printed line between some signal lines which are very sensitive to interference.

Development prospect:

advantage

Industrial policy support

The 11th Five-Year Plan of national economic and social development proposes to promote the electronic information manufacturing industry and vigorously develop core industries such as integrated circuits, software and new-type components according to the overall trend of digitalization, networking and intellectualization.

According to the "11th Five-Year Plan for the Development of Science and Technology in the Information Industry and the Outline of the Mid-2020 Long-term Plan" issued by the Ministry of Information Industry of China, printed circuit boards (especially multi-layer, flexible, flexible and rigid combined printed circuit boards and green and environmentally friendly printed circuit boards) are one of the 15 key areas for the development of China's electronic information industry in the next 5-15 years. In Dongguan, Shenzhen set up a lot of circuit board science and technology park.

Continued rapid growth of downstream industries

The rapid development of Chinese information electronics industry provides a good market environment for the rapid development of printed circuit board industry. The continuous growth of the output of electronic products such as electronic communication equipment, electronic computers and household appliances has provided a strong driving force for the rapid growth of the printed circuit board industry. In addition, the issuance of 3G licences will trigger massive investment in telecoms and demand for servers, storage and network equipment. According to the forecast of the Ministry of Information Industry, the growth rate of telecom fixed-asset investment in the Chinese mainland in 2006 and 2007 will reach 10.53% and 14.29% respectively.

Labor cost advantage, manufacturing shift to China

Due to the preferential measures of Asian countries in terms of labor resources, market, investment and tax policies, the manufacturing industry from the United States and Europe is attracted to Asia, especially China. China is blessed with a large number of electronic products and equipment manufacturers to set up factories in mainland China, and thus to drive the development of related industries. Printed circuit board as the basis of electronic components, the market demand growth is strong, the industry prospects.

Disadvantage

Product homogeneity is high, the proportion of high-end plate is low, the cost transfer ability is weak

Due to the fierce price competition, companies cannot transfer the rising cost to users, so they have to rely on their own factors to absorb it. In the case of rising material cost, PCB price will not change significantly, but once the material cost drops, the fierce competition will make the price drop.

The product scale structure and key technologies of local enterprises are insufficient

The production capacity and technical level of small and medium-sized and private manufacturers are in low grade products

There are no internationally accepted industry standards

Lack of self and recognized brand

Insufficient attention to research and development, unable to engage in research and development

Advanced equipment and technology are mostly mastered in foreign-funded enterprises

Did not form a complete set of industry self-discipline market

Waste disposal does not meet environmental standards

Opportunity

Downstream demand drives development

The market space brought about by the production reduction or product structure adjustment of major producing countries such as the United States and Europe

The international industrial transfer has brought about new technologies and management. The electronic information industry develops rapidly. The export increases by 40-45%, but the PCB industry lags behind the growth rate of the overall electronic information industry

Each manufacturer should look for market segments and products with high gross profit, and transform to higher-level products, such as soft board, soft and hard combined board, thick copper board, photoelectric XY control board, source board of TFT panel, automotive board, memory board, memory module board, PCB board with more than 10 layers. There are more opportunities.

threat

Upward pressure on raw material and energy prices

The main raw materials required for PCB production include copper coated plate, copper foil, semi-cured sheet, chemical solution, anode copper/tin/nickel, dry film, ink, etc. In addition, the production of PCB also needs to consume electric energy. The sharp rise in the price of precious metals, oil, coal and other basic energy also makes the PCB industry copper clad, copper foil and other main raw materials and energy prices have risen significantly, which brings a certain cost pressure to PCB manufacturers.