Conditions and market prospects for SMT chip processing

SMT chip processing is no stranger to us. The operation of general electronic equipment can not be separated from SMT chip processing. Nowadays, the electronic product industry is developing rapidly, and the requirements for chip processing are becoming higher and higher. It is also obvious that the process technology is reflected. There is also a certain process to complete the chip process, and this industry will grow with the continuous development of society. Now let's have a detailed understanding of "the specific requirements of SMT chip processing and the market prospects of SMT chip processing plants".

1、 SMT chip processing factory tells you the SMT chip processing conditions

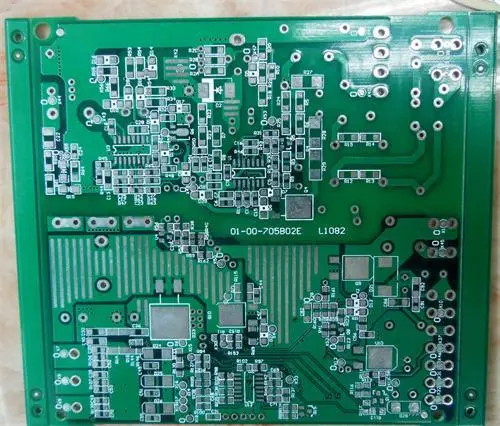

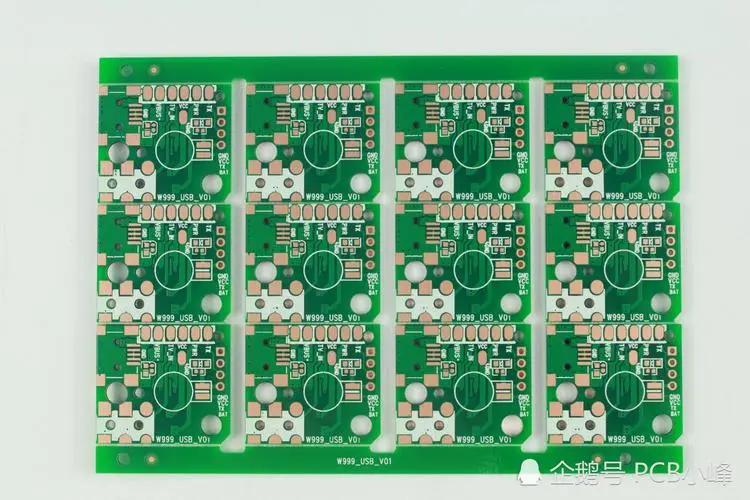

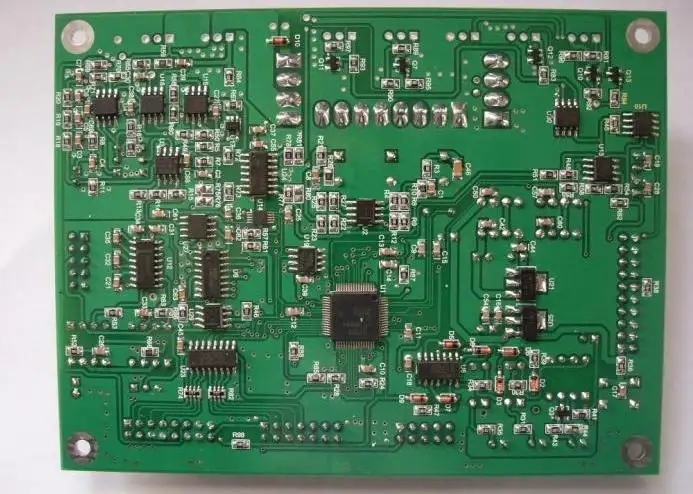

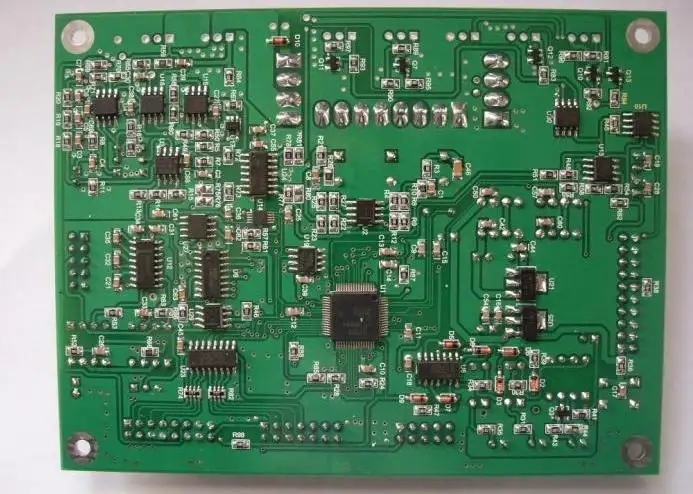

It is easy to understand that the SMT chip processing is to paste the capacitance or resistance on the electronic products with a dedicated machine, and then weld them to make them more solid and not easy to fall off the ground.

For example, we often use high-tech products such as computers and mobile phones. The motherboards inside them are densely and orderly arranged with tiny capacitance resistors. These capacitance resistors are pasted by using SMT chip processing technology. The capacitance resistors processed by high-tech chips are much faster than those manually pasted, and are not easy to make mistakes.

SMT is the abbreviation of Surface Mounted Technology, which is a popular processing technology in China's electronic industry. That is to say, SMT chip processing is a high-tech product, so I think it has high requirements for the processing workshop. What kind of workshop do you need? Let's find out.

SMT chip processing has certain requirements on the environment, humidity and temperature. In order to ensure the quality of electronic components and enable the processing quantity to be completed in advance, the working environment has the following requirements:

The first is the temperature requirement. The annual temperature in the factory building is 23 ± 3 ℃, which cannot exceed the limit temperature of 15~35 ℃. The second is the humidity requirement. The humidity in the SMT chip processing workshop has a great impact on the quality of products. The higher the ambient humidity, the easier the electronic components will be affected by moisture, which will affect the electrical conductivity. If the welding is not smooth and the humidity is too low, the air in the workshop will be easy to dry and generate static electricity, Therefore, when entering the SMT chip processing workshop, the processing personnel also need to wear anti-static clothing. Generally, the workshop is required to maintain a constant humidity of about 45%~70% RH.

Moreover, the cleanliness is required. The workshop should be free of any odor and dust, and the interior should be clean and free of corrosive materials. They will seriously affect the reliability of capacitance resistance, increase the failure repair rate of chip processing equipment, and reduce the production progress. The cleanliness of the workshop is about 100000 (BGJ73-84).

It is a requirement for the stability of the power supply. In order to avoid equipment failure during processing and affect the processing quality and progress, a voltage regulator should be added to the power supply to ensure the stability of the power supply.

2、 Development of SMT Processing Factory Market

Made in China, as a big manufacturing country, China has a large number and scale of OEM (processing and manufacturing with supplied materials) SMT chip processing plants in clothing, shoes and hats, bags and household appliances, as well as 3C digital consumer products, but in recent years, with the international economic downturn, domestic trade is blocked, domestic labor costs are rising, and the rent is rising. Now the rent in Beijing, Shanghai, Guangzhou and Shenzhen is rising every day, A large number of industrial plants have been demolished to build commercial residences, resulting in a doubling of factory rents. Even the president, an international giant, has determined that the housing price in Shenzhen is too high, the housing price is too high, and the factory rent is too high.

With the rise of labor costs, rent, water and electricity in China, and the disappearance of labor dividends year by year, OEM SMT chip processing enterprises are struggling. In order to find cheaper productivity, SMT chip processing enterprises reduce their production scale, refine their manpower, and move to places in Southeast Asia where human costs are cheaper. For example, they move to India, Vietnam to invest in production, and small SMT chip processing plants to maintain balance of income and expenditure; SMT chip processing plants began to build their own brands, trying to get rid of the hat of SMT chip processing agent, and from OEM to ODM (private brand design and manufacturing), from the agent to the Internet transformation.

PCB manufacturers, PCB designers and PCBA processors will explain the conditions and market prospects for SMT chip processing.