SMT printing machine (full automatic and semi-automatic explanation)

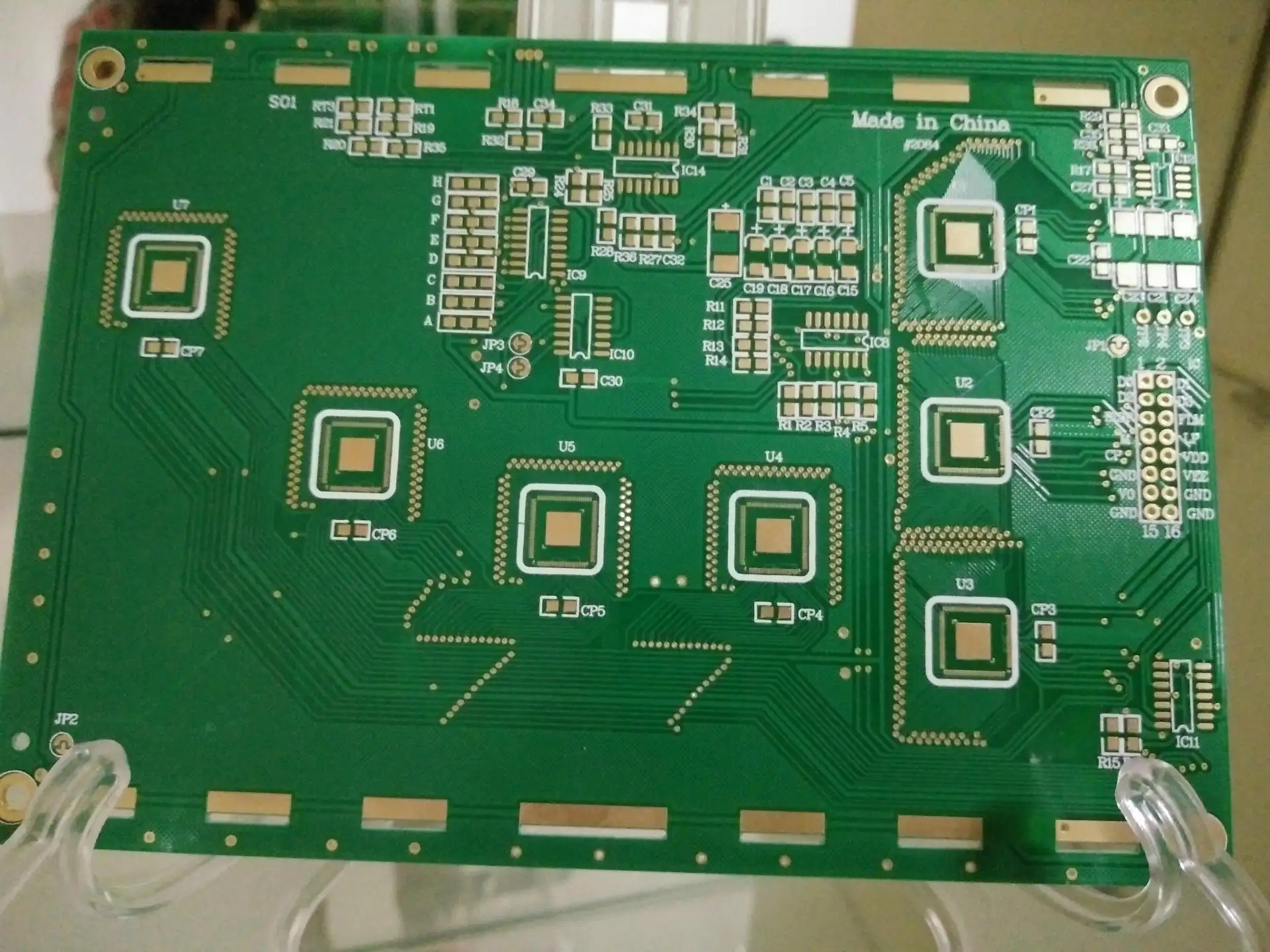

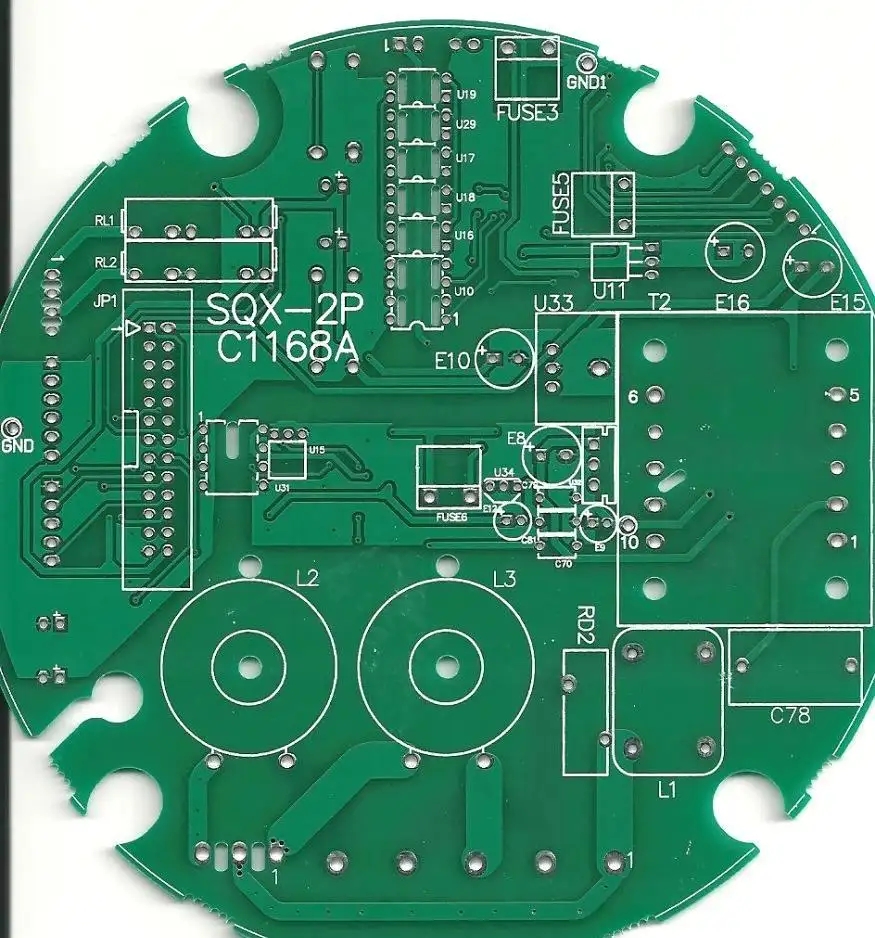

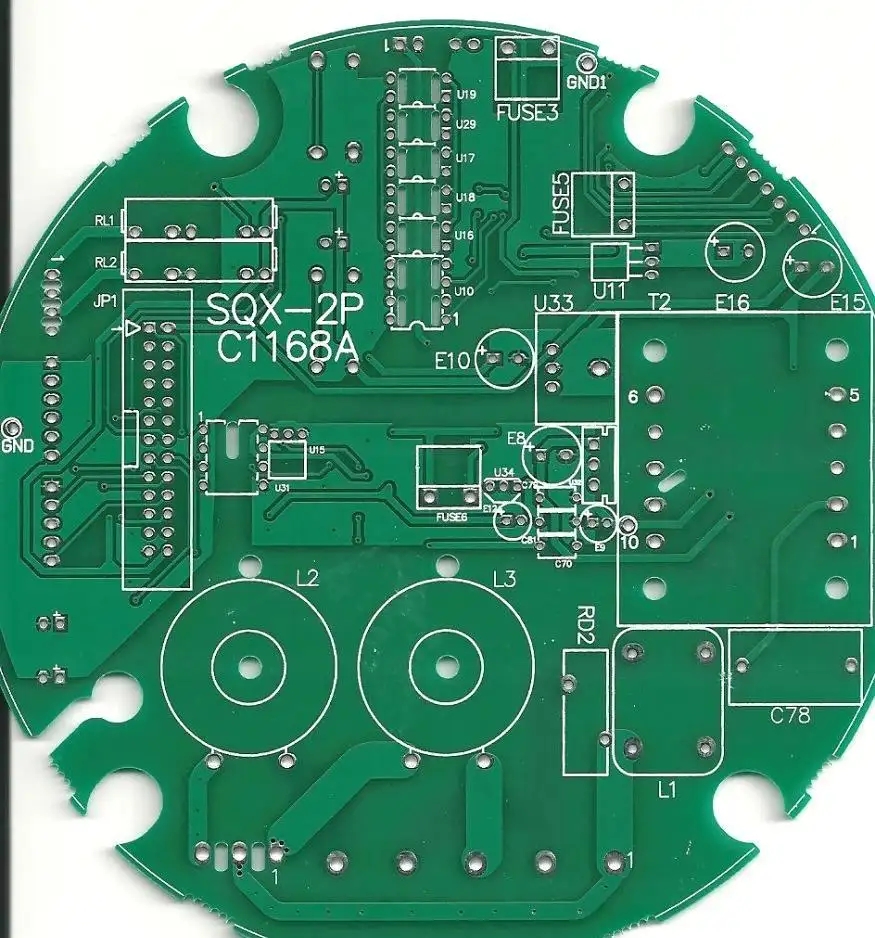

SMT printing machine is suitable for printing solder paste on the bonding pad of PCB bare board in the chip processing process, so that components can be welded to the PCB bonding pad in the next process, and after reflow soldering, a firm welding can be formed. The principle of SMT printing machine is very simple, that is, the solder paste placed on the steel mesh is scraped left and right by a scraper with a certain force and angle to make the solder paste leak through the steel mesh to the bare PCB pad under the steel mesh. Full automatic SMT printing machine Full automatic SMT printing machine is automatically completed from the loading of PCB bare board to the printing completion output track. PCB bare board enters full-automatic SMT printing

SMT printing machine is suitable for printing solder paste on the bonding pad of PCB bare board in the chip processing process, so that components can be welded to the PCB bonding pad in the next process, and after reflow soldering, a firm welding can be formed. The principle of SMT printing machine is very simple, that is, the solder paste placed on the steel mesh is scraped left and right by a scraper with a certain force and angle to make the solder paste leak through the steel mesh to the bare PCB pad under the steel mesh.

Full automatic SMT printing machine

The full-automatic SMT printing machine is automatically completed from the loading of PCB bare board to the printing completion output track. After the bare PCB board enters the full-automatic SMT printer, the equipment system will fix it, and then the optical camera will illuminate the Mark point on the PCB board to accurately locate its coordinate value. The coordinate position data of each pad on the PCB board has been input into the full-automatic SMT printer in advance, so the equipment will automatically adjust the XY axis, accurately cover the fixed steel mesh on the PCB board, and form a one-to-one position relationship between the steel mesh leakage and the PCB pad.

Then, the SMT printer will scrape from left to right and then from right to left according to the scraper angle and force data input in advance to leak the solder paste onto the PCB fixed below. After printing, loosen the fixed clamp, and put the PCB back to the track to flow out of the device. So far, the automatic printing process is completed.

Semi automatic SMT printing machine

The difference between semi-automatic SMT printing machine and full-automatic printing machine is that the PCB board needs to be manually fixed on the thimble at the bottom, then the switch is started with both hands, the cylinder drives the steel mesh containing solder paste to press down, and then the scraper moves left and right to form printing. After the printing is completed, the solder paste stencil device is lifted, and the printed solder paste PCB is manually taken out and placed on the turnover car or the track of the next process.

SMT printing machine plays an important role in the whole PCBA processing process, because the solder paste and red glue printing process largely determines the welding level of some precision devices. The shape, thickness and consistency of solder paste after printing are closely related to SMT printing machine equipment.