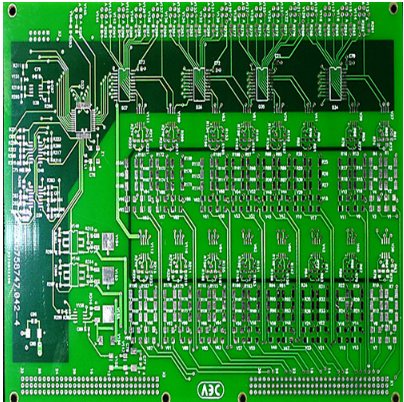

1. Definition of printed circuit board

Printed circuit board, also known as printed circuit board, printed circuit board, referred to as printed circuit board, English abbreviation PCB (printed circuit board) or PWB (printed circuit board), it is based on insulating board, cut into a certain size, in At least one conductive pattern is attached on it, and holes (such as component holes, fastening holes, metallized holes, etc.) are arranged to replace the chassis mounting of electronic components in the past, and the interconnection between them realizes the electronic components. Because such circuit boards are made using electronic printing techniques, they are called "printed" circuit boards. Printed circuit boards are the key interconnection of electronic devices and play an important supporting role in major breakthroughs in scientific research, communications, automotive, aerospace and other fields. It is an important foundation of modern science and technology. Its own development and the continuous improvement of related technologies have promoted the continuous development of social economy.

2. Development of my country's PCB industry

my country's PCB research and development work began in 1956, and from 1963 to 1978, the PCB industry gradually expanded. After more than 20 years of reform and opening up, due to the introduction of foreign advanced technology and equipment, single-sided, double-sided and multi-layer boards have achieved rapid development, and the domestic PCB industry has gradually developed from small to large. In 2002, it became the third largest PCB manufacturer. In 2003, PCB output value and import and export volume exceeded 6 billion US dollars, surpassing the United States for the first time and becoming the world's second largest PCB producer. The proportion of output value also increased from 8.54% in 2000 to 15.30%, an increase of nearly 1 times. In 2006, China replaced Japan as the world's largest PCB production base and the country with the most active technology development. my country's PCB industry has maintained a high growth rate of about 20% in recent years, much higher than the growth rate of the global PCB industry. On March 17, 2008, China Printed Circuit Industry Association established All-India Electronics Branch in Shanghai, marking a new level of development of my country's PCB industry.

3. my country's PCB technology development

Since 2005, the world's electronic circuit industry technology has developed rapidly, focusing on passive component PCB, inkjet PCB technology, laser direct imaging technology, optical technology PCB, and the application of nanomaterials on PCB. The development of PCB from mountbnng to packaging carrier board, as well as the chipization and integration of components, ball grid arrays, chip-scale packaging, and multi-chip modules are becoming more and more popular. The PCB package terminals are required to be miniaturized, the packaging is highly integrated, and the substrate is also required to undertake new functions. Embedded component printed boards appear to meet the requirements of high-density assembly.

The current advanced PCB manufacturing technology includes: build-up method to manufacture high-density inner (HDI) printed board technology, semi-additive method technology, thermosetting ink build-up method (TCD) technology, electroplating and filling blind hole technology, high-grade special materials PCB manufacturing technology, etc.

4. my country's PCB patent analysis

In the database of the State Intellectual Property Office, thematic searches are mainly carried out from the technical point of view of PCB production. The total number of patent applications from 1985 to 2010 was 2,385, and from 2000 to 2010 was 2,108. The total number of patents applied for in the past ten years accounted for 88% of the total number of patent applications. From 2000 to 2010, 1,798 invention patents and 310 utility models were applied for; 1,677 national patents and 431 international patents were applied for. Judging from the number of patents, it shows that my country's PCB industry has developed rapidly in the past ten years.

Foreign countries applying for patents in my country include: Japan, the United States, South Korea, Germany, France, Finland, Sweden, the Netherlands, Singapore, etc. It can be seen that many foreign companies have applied for patents in China, indicating that the Chinese market is increasingly influenced by foreign companies. Note that the competition is more intense. The top ten cities for patent applications in my country: Guangdong, Taiwan, Jiangsu, Shanghai, Zhejiang, Beijing, Fujian, Shandong, Hubei and Tianjin. Patent applications in my country are mainly distributed in the Pearl River Delta and the Yangtze River Delta along the southeast coast. The Yangtze River Delta, which accounts for more than 90% of the country, has developed rapidly in recent years, while the Northeast has developed relatively slowly.

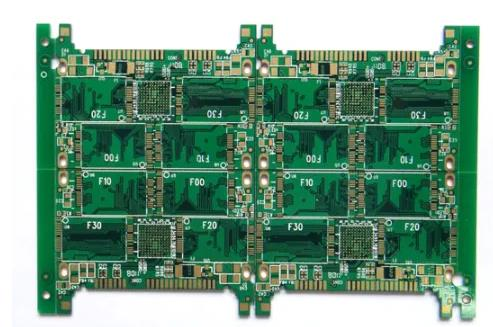

5. Analysis of my country's PCB product structure

From the perspective of the number of layers and the development direction of PCB, the PCB industry is divided into 6 major subdivision products such as single-sided, double-sided, conventional multi-layer boards, flexible boards,, HDI (high-density interconnection) boards and packaging substrates. From the product life From the perspective of the four cycles of the cycle, "introduction period - maturity period - recession period", single-sided and double-sided panels are in a recession period because they are not suitable for the current application trend of short, light and thin electronic products, and the proportion of their output value gradually declines. Developed countries and regions such as Japan, South Korea, and Taiwan rarely produce such products locally, and many large manufacturers have made it clear that they will no longer accept orders for double-sided panels.