The Basics of PCB Prototyping

A PCB (Printed Circuit Board )prototype is a model or sample of how the final PCB will look and function like. A printed circuit board prototype or low-cost PCB prototype is a small device used to connect electronic components to ensure the smooth functioning of a product. This process determines whether the proposed PCB design will perform as intended, revealing any possible flaws and thus enabling the designer to make any necessary changes. Any other improvements or alternatives that the designer might think of are also introduced at this stage. Mass production of any new product is inseparable and PCB prototyping services cannot simply start without a prototyping stage.

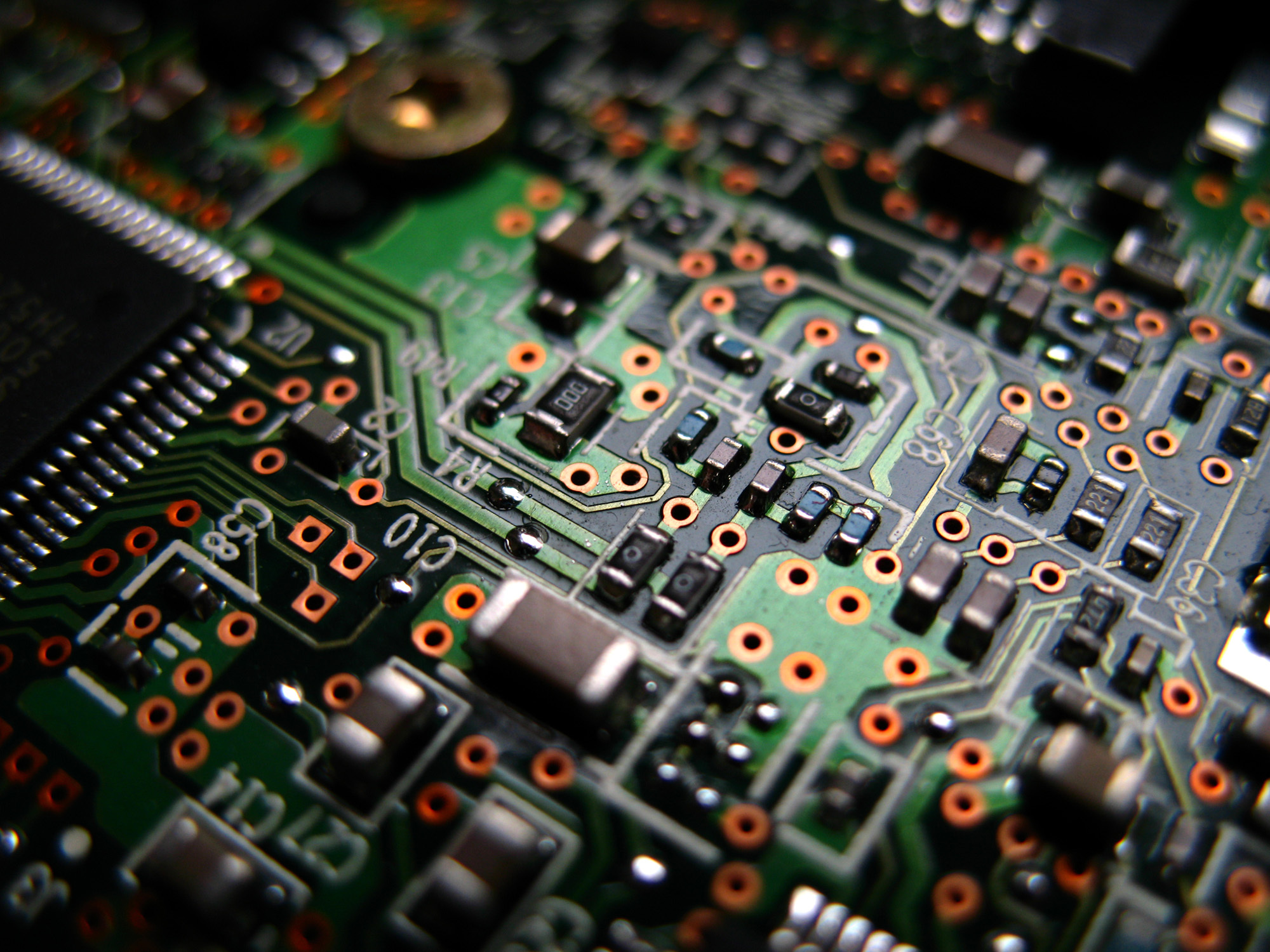

PCB prototype

Prototyping won't necessarily reveal any flaws, because sometimes the design is perfect. After the PCB prototype board is completed, the electronic components of the product are connected into a PCA (Printed Circuit Assembly), usually with the help of soldering. The manufacturer or customer can then provide their opinion on the PCB and other suggestions/improvements they may have. PCB prototyping service designers should always be prepared for any possible outcome, so any rework at this stage should not be considered an additional cost. Bypassing prototyping and participating in the mass production of PCB prototype boards will only make it fail, and it will certainly be disastrous in terms of wasted effort, time and money.

Following are the generalized stages of PCB prototyping. The first is called a breadboard test or proof of principle. This will check if the logic behind the PCB prototype board is achievable. Next is to check the size (preferred size) aspect of the intended PCB prototype board. After this phase, a visual mockup is generated and, if approved, the final phase of functionality and appearance begins. What is achieved at this moment is the closest to what the actual PCB prototype board will look like. Usually, in the prototype design of PCB, the simulation of the current in the board and the state of the circuit are the two most important processes. Actual components and materials are implemented for the final model or prototype only until the simulated system works as required.

Advances in technology and computerization have paved the way for mass convenient production of PCB/s across the globe. Prototyping is a modern system used to cost-effectively manufacture PCB boards, mainly the main electronic components.

Actively introduce PCB prototype manufacturers, prototype machines are not ordinary commodities like copiers, users can use them easily. PCB prototype boards need to be researched before use. As a modern, affordable item and investment, judging equipment before acquiring it takes a lot of experience.

The Basics of PCB Prototyping

Benefits - If the business is involved in mass production, the first process is to make a master copy before it is checked and it can continue to the next step of producing millions. With the PCB milling system, the cumbersome traditional process is reduced due to the guaranteed speed of creation and testing.

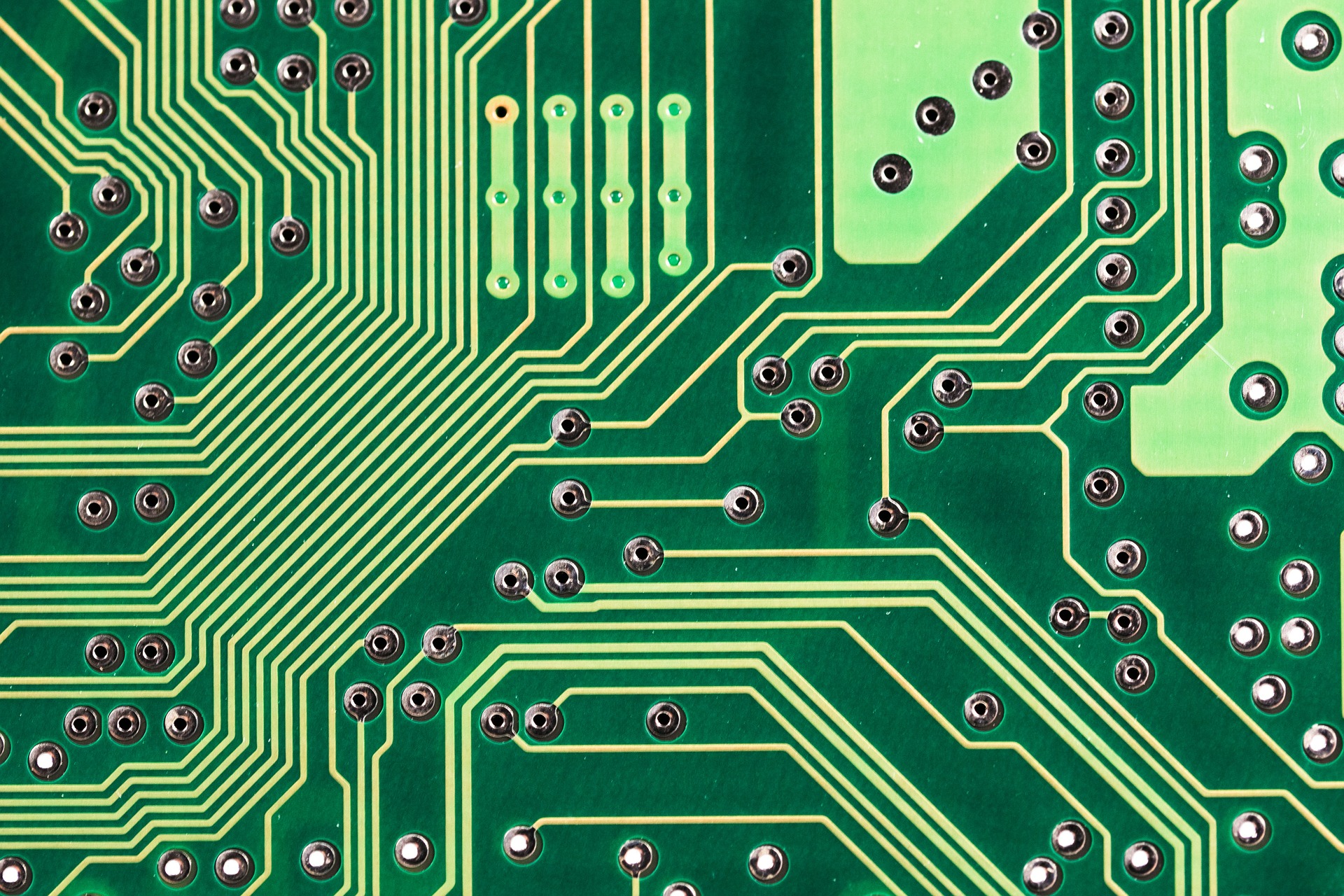

Compared to chemical etching, chemical-free, PCB milling is done cleanly by subtractive methods that do not involve the use of chemicals. Cut the board to remove the copper sections. The speed at which tasks are completed is precisely controlled by the user.

Compact - Imagine a machine handling multiple complex tasks of milling, drilling, milling and other special processes, where the tasks are all done by prototyping the PCB board. The only additional item required to operate the unit is an industrial vacuum to back it up for maintenance. Compactness can be achieved during setup, which is also part of the training required to handle a prototype.

Mechanism - PCB prototyping is a precisely controlled device that is highly mechanically manufacturable. It involves drive systems fully manipulated by design components. Once presented, it all depends on the integration of the user and the software, coordinating the movement of the head in its coordinates (x, y and z). It is computerized, making the repeat process error-free.

Safe - Designed for high complexity using small bits for wiring, it has been tailored to the rigidity of the application. However, for safety reasons, users need to wear protective glasses for the eyes. The tiny dust that is emitted needs to be vacuumed all the time.

The production of prototypes is a time-bound process - it should take the least amount of time for the actual PCB prototype maker. Companies that provide PCB prototyping services may also be involved in PCB prototype manufacturers. Hence, these companies strive to develop good/perfect prototypes. Advances in technology and more computerization have accelerated the process of prototyping and manufacturing PCBs and making them as error-free as possible. So it is wise to choose a PCB prototype maker with the latest technology that will ensure a near zero margin of error, avoid the use of harmful chemicals, and keep the PCB size as small as possible, but again they are what modern electronics require .

Years of experience are enough to use PCB prototyping equipment effectively. It makes manufacturing safe, easy, efficient and rewarding. It is best to upgrade technology through the use of computerized equipment.