With the rapid development of electronic information industry, electronic products are developing towards miniaturization, functionality, high performance and high reliability. From the general surface mount technology (SMT) in the mid-1970s to the high-density interconnect surface mount technology (HDI) in the 1990s, as well as the application of various new packaging technologies such as semiconductor packaging and IC packaging in recent years, electronic installation technology has been developing towards high-density.

At the same time, the development of high-density interconnection technology promotes PCB to develop in the direction of high-density. With the development of installation technology and PCB technology, the technology of copper clad laminate, as a PCB substrate material, is also progressing.

Experts predict that the average annual growth rate of the world's electronic information industry in the next 10 years will be 7.4%. By 2020, the world's electronic information industry market will reach 6.4 trillion US dollars, including 3.2 trillion US dollars for electronic complete machines. Communication equipment and computers account for more than 70% of them, reaching 0.96 trillion US dollars. It can be seen that the huge market of copper clad laminate, as an electronic basic material, will not only continue to exist, but also continue to develop at a growth rate of 15%. Relevant information released by CCL Industry Association shows that in the next five years, in order to adapt to the development trend of high-density BGA technology, semiconductor packaging technology, etc., the proportion of high-performance thin FR-4, high-performance resin substrate, etc. will become larger and larger.

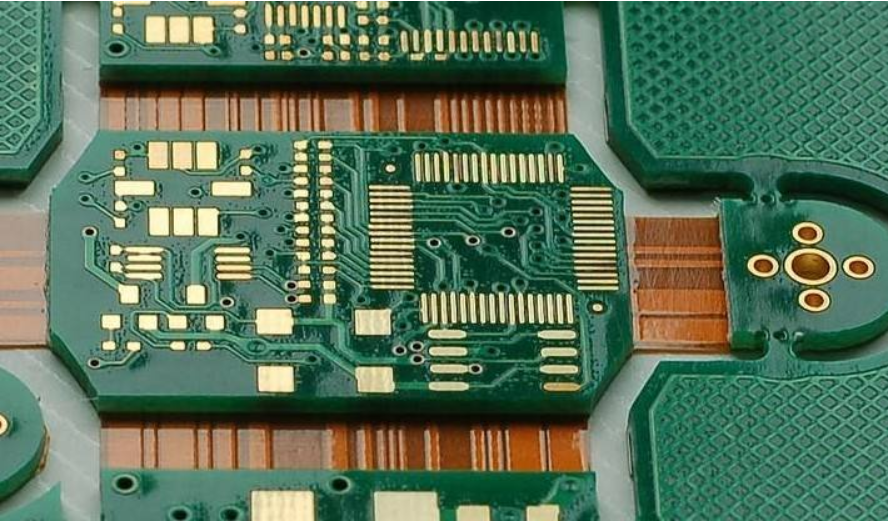

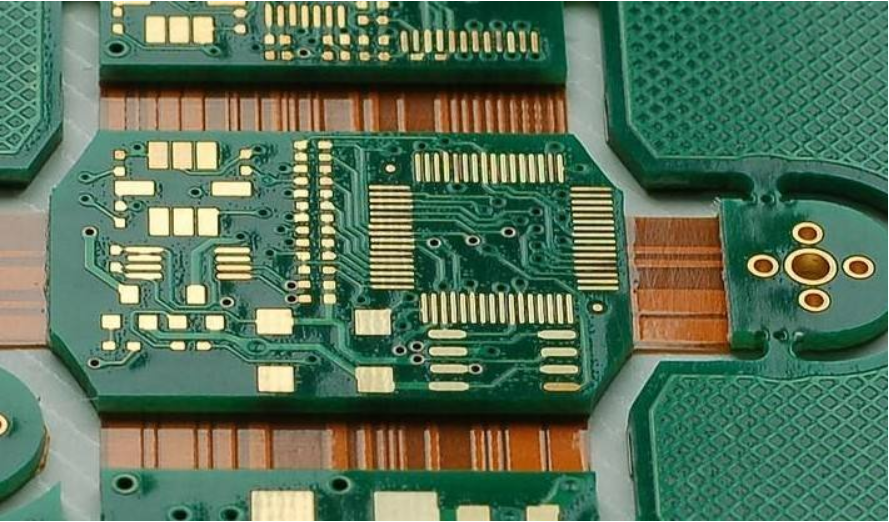

As the substrate material in PCB manufacturing, copper clad laminate (CCL) mainly plays the role of interconnection, conduction, insulation and support for PCB circuit boards, and has a great impact on the transmission speed, energy loss, characteristic impedance, etc. of signals in the circuit. Therefore, the performance, quality, processability in manufacturing, manufacturing level, manufacturing cost, long-term reliability, stability, etc. of PCB depend on the copper clad laminate material to a large extent.

The technology and production of copper clad laminate have gone through more than half a century of development. Now the annual output of copper clad laminate in the world has exceeded 300 million square meters. Copper clad laminate has become an important component of basic materials in electronic information products. The CCL manufacturing industry is a sunrise industry. With the development of electronic information and communication industry, it has broad prospects. Its manufacturing technology is a new and high-tech technology with multiple disciplines crossing, infiltrating and promoting each other. The development of electronic information technology shows that CCL technology is one of the key technologies to promote the rapid development of electronic industry.

The key tasks of China's copper clad laminate (CCL) industry in the future development strategy, specifically in terms of products, should make efforts on the five categories of new PCB substrate materials, that is, through the development of five categories of new substrate materials and technological breakthroughs, China's CCL cutting-edge technology has been improved. The development of these five categories of new high-performance CCL products listed below is a key topic for Chinese CCL engineers and technicians in the future research and development.

With the development of PCB technology, the technology of copper clad laminate (CCL), as the PCB substrate material, has made continuous progress