1、 PCB substrate material - lead-free compatible copper clad laminate

At the meeting of the European Union on October 11, 2002, two "European Directives" on environmental protection were adopted. They will formally implement the resolution on July 1, 2006. The two "European Directives" refer to the "Waste Directive on Electrical and Electronic Products" (WEEE for short) and the "Restriction Order on the Use of Certain Hazardous Substances" (RoHs for short). In these two regulatory directives, the use of lead containing materials is explicitly mentioned. Therefore, the best way to deal with these two directives is to develop lead-free copper clad laminate as soon as possible.

2、 PCB substrate material - high-performance copper clad laminate

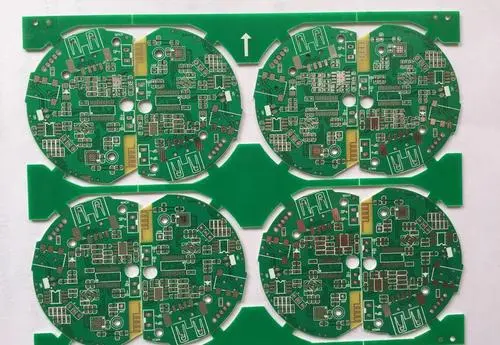

The high-performance copper clad laminate referred to here includes copper clad laminate with low dielectric constant (Dk), copper clad laminate for high frequency and high speed PCB, copper clad laminate with high heat resistance, and various substrate materials for laminated multilayer board (resin coated copper foil, organic resin film constituting the insulation layer of laminated multilayer board, glass fiber reinforced or other organic fiber reinforced semi solidified sheets, etc.). In the next few years (to 2010), in the development of this kind of high-performance copper clad laminate, according to the forecast of the future development of electronic installation technology, the corresponding performance index value should be reached.

3、 PCB substrate material - substrate material for IC packaging carrier

It is a very important subject to develop the substrate materials for IC packaging carrier (also known as IC packaging substrate). It is also an urgent need to develop IC packaging and microelectronics technology in China. With the development of IC packaging towards high frequency and low power consumption, IC packaging substrate will be improved in such important properties as low dielectric constant, low dielectric loss factor and high thermal conductivity. An important subject for future research and development is the effective thermal coordination and integration of substrate thermal connection technology - thermal emission, etc.

In order to ensure the freedom of IC packaging design and the development of new IC packaging technology, it is indispensable to carry out model test and simulation test. These two tasks are of great significance to master the characteristic requirements of substrate materials for IC packaging, namely, the understanding and mastery of its electrical performance, heating and cooling performance, reliability and other requirements. In addition, we should further communicate with the IC packaging design industry to reach a consensus. The performance of the substrate materials developed shall be provided to the designer of the whole electronic product in time, so that the designer can establish an accurate and advanced data base.

The IC packaging carrier also needs to solve the problem of inconsistent thermal expansion coefficient with semiconductor chips. Even for the multilayer board of the build-up method suitable for the fabrication of micro circuits, there is a problem that the thermal expansion coefficient of the insulating substrate is generally too large (generally the thermal expansion coefficient is 60 ppm/℃). However, the thermal expansion coefficient of the substrate is about 6ppm close to that of the semiconductor chip, which is indeed a "difficult challenge" to the substrate manufacturing technology.

In order to adapt to the development of high-speed, the dielectric constant of the substrate should reach 2.0 and the dielectric loss factor should be close to 0.001. For this reason, it is predicted that a new generation of printed circuit boards that transcends the boundaries of traditional substrate materials and traditional manufacturing processes will appear in the world around 2005. The technical breakthrough, first of all, is in the use of new substrate materials.

Predicting the future development of IC packaging design and manufacturing technology requires more strict substrate materials. This is mainly reflected in the following aspects:

1. High Tg property corresponding to lead-free flux.

2. Achieve the low dielectric loss factor matching the characteristic impedance.

3. Low dielectric constant corresponding to high-speed( ε It should be close to 2).

4. Low warpage (improvement of flatness of substrate surface).

5. Low moisture absorption.

6. Low thermal expansion coefficient, making the thermal expansion coefficient close to 6ppm.

7. Low cost of IC packaging carrier.

8. Low cost substrate materials for embedded components.

9. Improve the basic mechanical strength in order to improve the thermal shock resistance. The substrate material is suitable for temperature cycling from high to low without reducing performance.

10. Green substrate material with low cost and suitable for high reflow soldering temperature.

4、 PCB substrate material Copper clad laminate with special functions

The special function copper clad plate referred to here mainly refers to: metal base (core) copper clad plate, ceramic base copper clad plate, high dielectric constant plate, copper clad plate (or substrate material) for embedded passive component type multilayer plate, copper clad plate for optical electrical circuit substrate, etc. The development and production of this kind of CCL is not only the need for the development of new technology of electronic information products, but also the need for the development of China's aerospace and military industries.

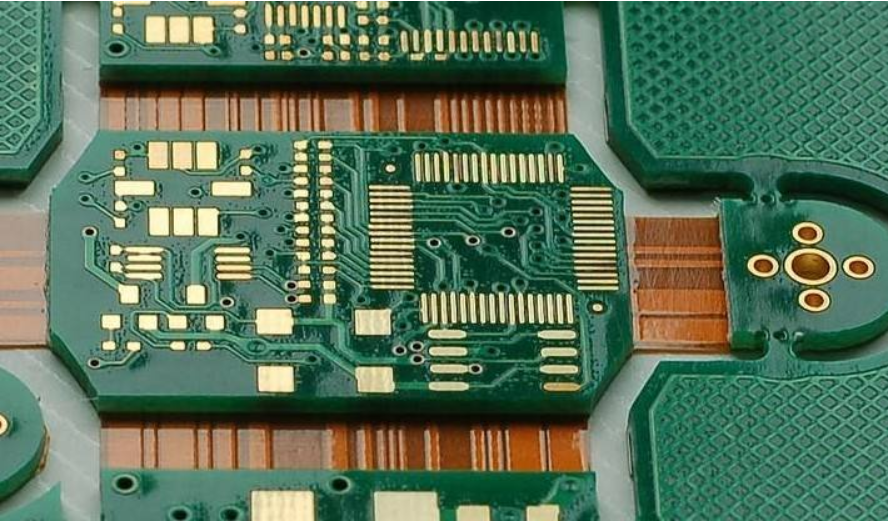

5、 PCB substrate material High performance flexible copper clad laminate

At present, the output value of FPC produced in the world last year reached about 3 billion to 3.5 billion US dollars. In recent years, the world's FPC production has been growing. Its proportion in PCB has also increased year by year. In the United States and other countries, FPC accounts for 13% - 16% of the total output value of printed circuit boards, and FPC is increasingly becoming a very important and indispensable type of PCB.

summary

The development of CCL technology and production is synchronous and inseparable with the development of electronic information industry, especially PCB industry. This is a process of continuous innovation and pursuit. The progress and development of CCL are also driven by the innovation and development of electronic complete machine products, semiconductor manufacturing technology, electronic installation technology, and PCB manufacturing technology. In this case, it is particularly important to make joint progress and synchronous development.