1、 What fields are multilayer PCB generally used in?

Multilayer PCB circuit board is generally used in communication equipment, medical devices, industrial control, security, automotive electronics, aviation, computer peripheral and other fields; As the "core main force" in these fields, with the continuous increase of product functions, the lines are more and more intensive, and the corresponding market requirements for board quality are also getting higher and higher, and the customer demand for medium and high TG circuit boards is constantly increasing.

2、 The particularity of multilayer PCB

Ordinary PCB plates will have deformation and other problems under high temperature, and the mechanical and electrical characteristics may also decline sharply, reducing the service life of the product. The application field of multilayer PCB is generally located in the middle and high-end science and technology industry, which directly requires that its sheet materials have high stability, high chemical resistance, and can withstand high temperature, high humidity, etc

Focus

Therefore, multi-layer PCB boards shall be made of at least TG150 or more boards, so as to reduce the influence of external factors and prolong the service life of the products.

3、 Stability and high reliability of high TG board types in PCB

What is the PCB TG value?

TG value: TG is the highest temperature at which the steel of the plate is maintained. TG value refers to the temperature at which the amorphous polymer (including the amorphous part of the crystalline polymer) changes from the glass state to the high elastic state (rubber state).

The TG value is the critical temperature at which the substrate melts from solid to rubber liquid.

The TG value is directly related to the stability and reliability of PCB products. The higher the TG value is, the stronger the stability and reliability are.

High TG plate has the following advantages:

Focus

(1) High heat resistance, which can reduce the floating of PCB pad during infrared hot melting, welding and thermal shock.

(2) Low coefficient of thermal expansion (low CTE) can reduce the warpage caused by temperature factors, and reduce the copper fracture at the hole corner caused by thermal expansion. Especially in PCB boards with eight or more layers, the performance of plated through holes is better than that of PCB boards with general TG values.

(3) It has excellent chemical resistance, which enables PCB board to remain intact in the process of wet treatment and under the immersion of many chemical solutions.

JETTOBON knows that in general, the quality, performance and reliability of PCB boards made of medium and high TG boards are better than those of low TG boards.

Therefore, Jieduobang has insisted on the use of high-quality boards for many years, meticulously committed to providing customers with bulk and proofing services for medium and high TG circuit boards, and actively providing high-quality profit producing boards and Jiantao Class A boards;

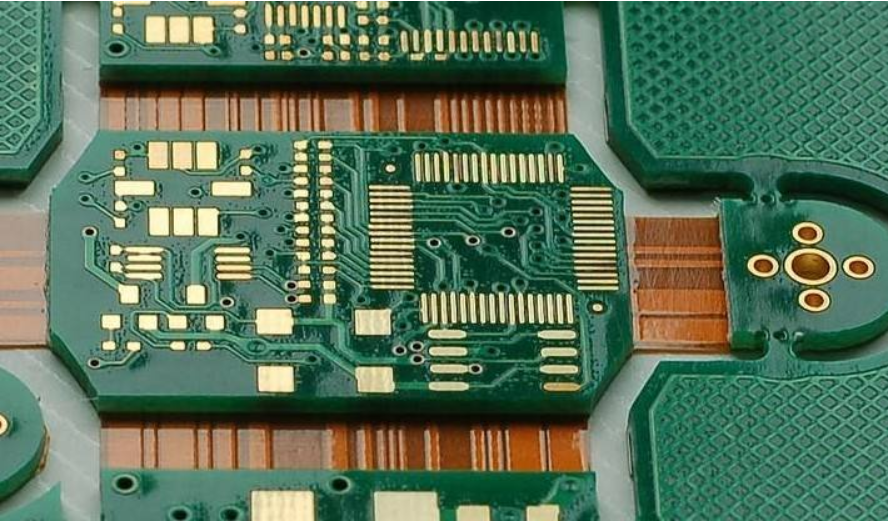

High quality circuit board

Of course, the batch and proofing of special plates (aluminum base plate, copper base plate, PCB version, high-frequency plate, FPC soft plate, etc.) are also easy to do.