Electrostatic protection and its importance is a system engineering because electrostatic damage to sensitive electronic components is great in PCBA foundry and material processing. SMT processing plants should first establish and check the anti-static basic engineering, such as ground wire, floor mat, table integration, environmental anti-static Wang engineering, etc. Because once the equipment enters the workshop, if it is found that the environment does not meet the requirements, it will be very troublesome to rectify. After the basic project of smt patch processing line is completed, if the site is dedicated to long-term products, anti-static equipment should be configured according to the anti-static requirements of long-term products. If the device is of multiple varieties, configure the device according to the highest level requirements. The following SMT patch OEM kingford will introduce what protective facilities need to be equipped in the process of PCBA OEM processing and material processing and production:

Do not use wood floors or lay wool, linen, chemical fiber floors or ordinary leather floors in the ESD work area. Select a floor composed of ESD conductors, such as an ESD raised floor or a common floor, and ground the floor effectively.

Antistatic ceiling materials should be selected in the anti-static area. Gypsum board is generally allowed and ordinary plastic products are prohibited. The wall fabric should use anti-static wallpaper, generally allowed to use plaster paint or lime paint, do not use ordinary wallpaper and plastic wallpaper.

The antistatic device on the production line of the antistatic paste should be separated from the lightning protection wire, the grounding device is reliable, the electrostatic leakage system is complete, the workshop is maintained constant temperature and humidity, the general temperature is controlled at (25±2)℃, the relative humidity is 65%5%; The entrance shall be equipped with ion air bath equipment. Triangle ESD electrostatic sensitive symbol, painted with a scratch hand, indicating that the object is very sensitive to ESD damage.

2, how to do the preparatory work before the circuit board production

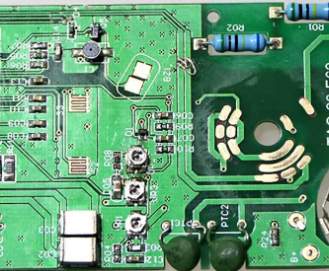

From sample to mass production, we must make full preparations, so as to ensure that all products can be successfully launched and avoid problems in various aspects in this process. Because the production efficiency will have a great impact on the circuit board, we can make preparations in advance, and then we can be more secure in the process of use. So how do you prepare in advance when you do it?

Before the production of the circuit board, we must do a good job in advance of the procurement of raw materials, but also do a good job in all aspects of design, can be targeted to understand the actual situation, for the whole preparation work to do more appropriate, so as to effectively avoid other subsequent problems, most people before the production work, For the purchase of raw materials, it is necessary to actively consider the situation of the whole market, and timely make more plans in various aspects. Only after these things are done more properly, can better results be achieved.

Since we need to do production work, we must further inspect the samples without any problems. For poor testing or other situations, we must take timely countermeasures, ensure the quality of the products produced and plan all aspects well in advance, so as to effectively avoid many other problems. Therefore, we must put all these preparations in advance to be able to do more in place.

The preparation work directly affects the subsequent situation. Before the production of circuit boards, the preparation work we do is equally important. We not only need to understand the production process and determine the quality of specific samples, but also need to pay attention to the actual content of various aspects and take these aspects into consideration. Let the quality of the whole product can be more guaranteed, so that we in the future application process, the overall effect will be better. The preparatory work we have done will certainly affect the specific situation in the future.