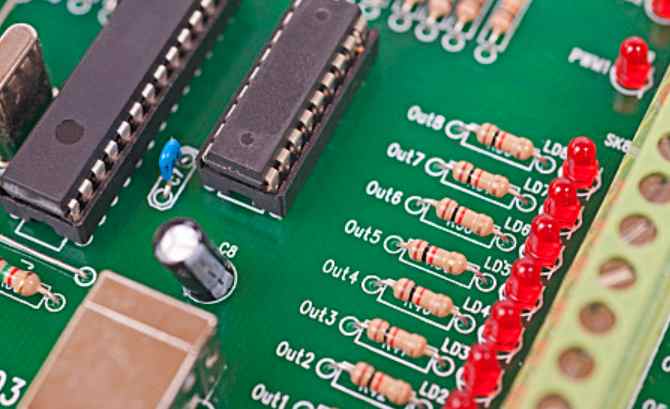

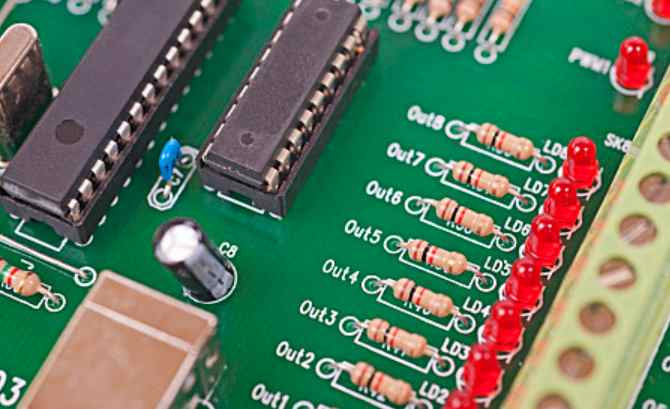

How much do you know about the interesting knowledge of the circuit board? According to the number of layers of the circuit board, it can be divided into single panel, double panel, four layer board, six layer board and other multilayer boards. The advantages of the circuit board greatly reduce wiring and assembly errors, improve the level of automation and production, and continue to high precision, high density and high reliability direction. What is the main process of circuit board design? Circuit board design should pay attention to those matters?

What is the main process of circuit board design?

1. System specifications

First of all, the system specifications of the electronic equipment should be planned. It includes system functionality, cost constraints, size, operation, and so on.

2. Functional block

(1) Next, we must make the functional block diagram of the system. The relationships between blocks must also be marked.

(2) Divide the system into several PCBS. If the system is divided into several PCBS, it can not only reduce the size, but also make the system have the ability to upgrade and exchange parts. System function block diagram provides the basis for our segmentation. For example, computers can be divided into main board, video card, sound card, floppy disk drive, power supply, and so on.

(3) Decide the packaging method, and the size of each PCB when the technology and the number of circuits used in each PCB have been decided, the next is to decide the size of the board. If the PCB is designed to be too large, then the packaging technology has to be changed, or re-split the action. The quality and speed of the diagram should also be taken into account when selecting the technology.

Two, circuit board design should pay attention to those matters?

1. Avoid arranging important signal lines, such as clock and reset signal, at the edge of PCB.

2. The distance between the ground wire of the housing and the signal cable should be at least 4mm; Keep the aspect ratio of the housing ground wire less than 5:1 to reduce inductance effect.

3. The devices and wires that have been located will be locked with the LOCK function, so that they will not be moved by mistake later.

4. The minimum width of the wire should not be less than 0.2mm (8mil). In high-density and high-precision printed lines, the width and spacing of the wire are generally preferable to 12mil.

5. The principles of 10-10 and 12-12 can be applied in wiring between DIP-packaged IC feet, that is, when two wires pass between two feet, the diameter of the pad can be set to 50mil, the width and line distance are both 10mil; when only one wire passes between two feet, the diameter of the pad can be set to 64mil, and the line width and line distance are both 12mil.

6. When the diameter of the pad is 1.5mm, in order to increase the stripping strength of the pad, the length of the pad is not less than 1.5mm, the width is 1.5mm and the oblong pad can be used.

7. When the design meets the wire of the welding pad connection, the connection between the welding pad and the wire should be designed into a droplet shape, so that the welding pad is not easy to peel, and the wire and the welding pad are not easy to disconnect.

8. There should be open Windows and heat dissipation holes on the large area copper application design, and the open Windows should be designed into a network.

9. Shorten the connection between high-frequency components as much as possible to reduce their distribution parameters and mutual electromagnetic interference. Easily disturbed components should not be too close to each other, input and output components should be as far away as possible.

Above is my answer to "What is the main process of circuit board design? What should we pay attention to in circuit board design?" The introduction, for your reference, I wish you a happy life!

Information and steps required for PCB design

PCB design is based on circuit schematics to achieve specific functions on the PCB. PCB design should consider many factors, such as external connection layout, layout design, internal electronic components optimization layout, etc.

1. The function of PCB design is to standardize the design operation, improve the production efficiency and improve the quality of electronic products. 2. EAGLE layout. 3. BORDSTATION departure and EE. 4. Cadencespb software.

The PCB design steps are as follows:

1. Layout design.

2. Placement order.

3. Check the layout.

Materials required for PCB design:

1. A complete electronic document format that generates the correct netlist and provides the required layout and functionality of the PCB.

2. Mechanical dimensions: Provide PCB with multi-clock physical information, such as the specific position and direction of electronic device identification.

3. Equipment packaging: Provide PCB circuit board equipment packaging library, packaging methods and electronic material specifications.

4. Wiring guide: PCB special signal requirements and impedance design specifications.