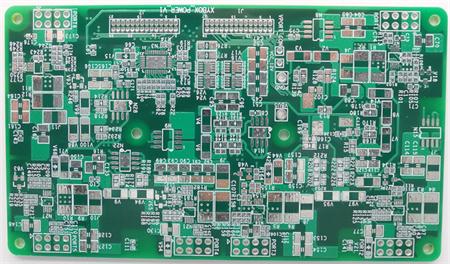

Compared with a single PCB panel, no matter how its internal quality is, we can see the differences through the surface. These differences are critical to the durability and functionality of a PCB during its entire life. The main advantage of a multilayer PCB board is that it resists oxidation. With diversified structure, high density, and coating technology on the surface, it can ensure the quality and safety of the circuit board and can be used with confidence. The following are the important features of the high reliability multilayer board, that is, the advantages and disadvantages of the multilayer PCB board:

1. The copper thickness of hole wall of multilayer PCB board is 25 μ m normally;

Advantages: Enhanced reliability, including improved z-axis extension resistance.

Disadvantages: but there are also certain risks: under the actual use, the electrical connectivity (inner layer separation, hole wall fracture) during blowing out or degassing, assembly, or the possibility of failure under load conditions. IPC Class2 (the standard of most factories) requires that the copper plating of multilayer PCB boards should be less than 20%.

2. No welding repair or open circuit repair

Advantages: The perfect circuit ensures reliability and safety without maintenance and risk.

Disadvantages: If the maintenance is improper, the multilayer PCB board is open. Even if properly fixed, there may be a risk of failure under load conditions (vibration, etc.), which may lead to failure in actual use.

3. The cleanliness requirements of IPC specifications are exceeded

Advantages: improving the cleanliness of multilayer PCB board can improve the reliability.

Risk: The residue on the terminal block and the accumulation of solder will bring risks to the anti welding layer, and the ionic residue will lead to the risk of corrosion and contamination of the welding surface, which may lead to reliability problems (poor welding contact/electrical failure) and ultimately increase the probability of actual failure.

4. Strictly control the service life of each surface treatment

Advantages: welding, reliability and reduced risk of moisture intrusion

Risk: It is the surface treatment of old multilayer PCB boards that may lead to metallographic changes and solderability problems, while water intrusion may lead to problems in the assembly process and/or the actual use of delamination, separation (open circuit) of inner wall and wall, etc.

No matter in the manufacturing and assembly process or in actual use, multilayer PCB boards must have reliable performance, which is of course related to the equipment and technology level of PCB printing plants.