What are the differences between the layers of a PCB?

During PCB design, I found that many people do not know enough about the layers in PCB, especially novices, who are vague about the role of each layer. So today, let's take a look at the differences between different layers when using the Altium Designer palette.

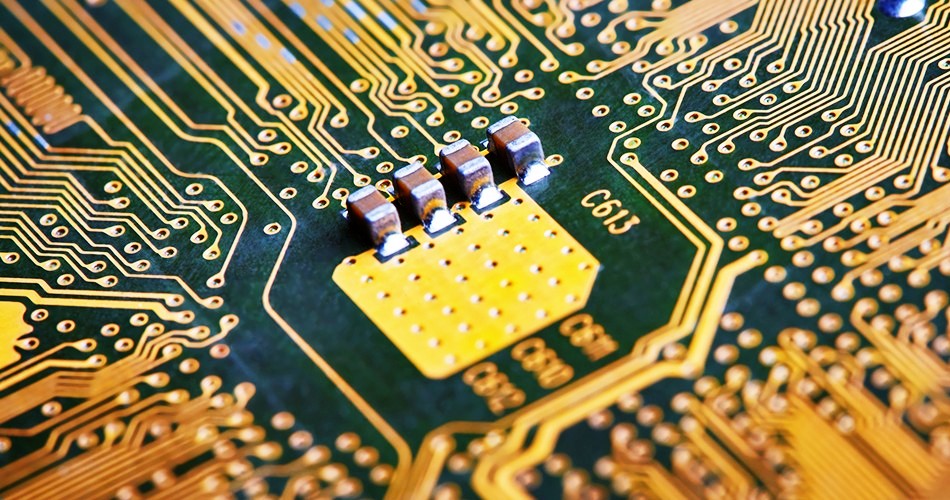

1. Signal layer

The signal layer is divided into Top Layer and Bottom Layer, which are the layers with electrical connections. They can place components and wires.

2. Mechanical layer

Mechanical (mechanical layer) defines the appearance of the entire PCB. The reason why "mechanical" is emphasized is that it does not have electrical attributes. Therefore, it can be safely used to sketch shapes, sketch mechanical dimensions, place text, etc., without worrying about any changes to the electrical characteristics of the board. Up to 16 mechanical layers can be selected.

3. Silk screen layer

Top Overlay and Bottom Overlay are used to define the screen printed characters on the top and bottom layers, which are text symbols printed on the solder mask layer, such as component names, component symbols, component pins and copyrights, to facilitate future circuit welding and error checking.

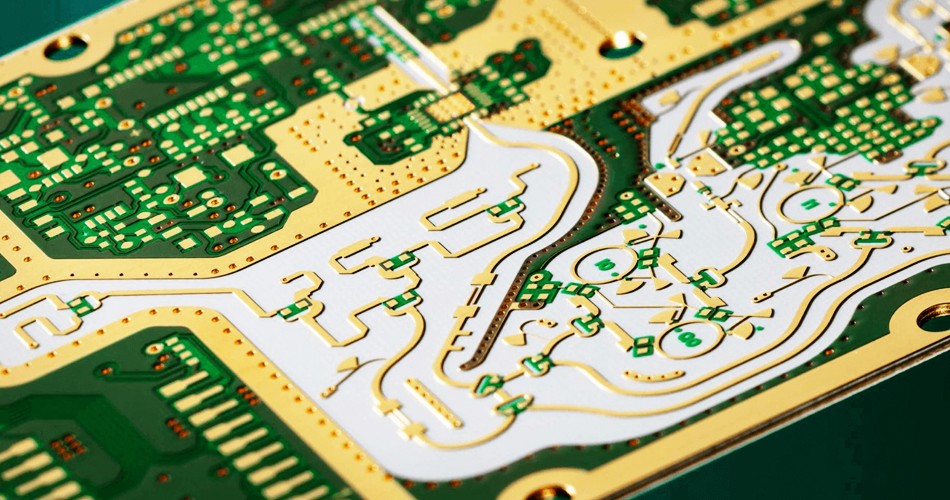

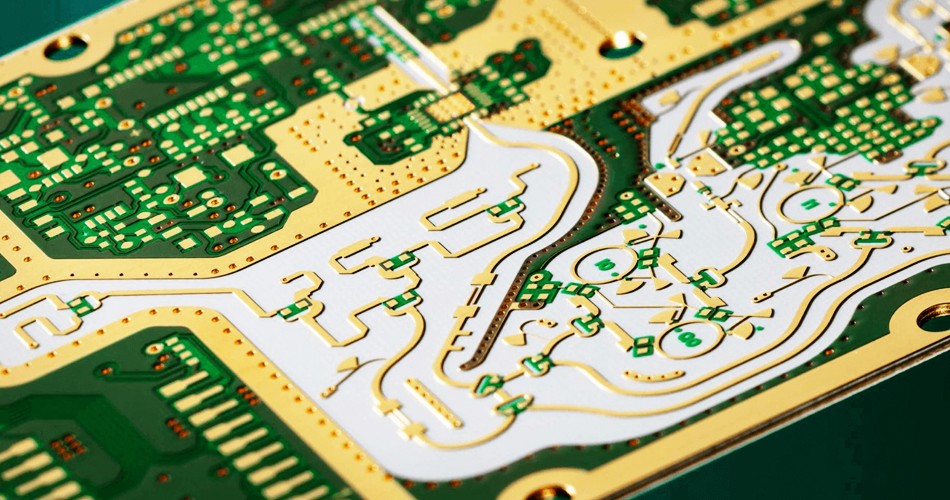

4. Solder paste layer

The solder paste layer includes the top paste layer and the bottom paste layer. It refers to the exposed surface mounted pads that we can see, that is, the parts that need to be coated with solder paste before welding. Therefore, this layer is also useful for hot air leveling of pad and welding steel mesh fabrication.

5. Solder mask

Solder resistance layer is also often referred to as "window opening", including the top solder layer and bottom solder layer. Its function is opposite to that of solder paste layer, which refers to the layer to be covered with green oil. This layer does not stick solder to prevent short circuit of excess solder at adjacent welding points during welding. The solder mask covers the copper film conductor, preventing the copper film from oxidation in the air too quickly, but leaving a place at the solder joint, not covering the solder joint.

Conventional copper coating or wiring is covered with green oil by default. If we treat the solder barrier layer accordingly, it will prevent the green oil from covering and expose the copper.

6. Borehole layer

The drilling layer includes two drilling layers, namely, Drill Grid and Drill Drawing. The drilling layer is used to provide drilling information during the manufacturing process of the circuit board (such as pads, which need to be drilled through holes).

7. No wiring layer

Keep Out Layer is used to define the boundary of the wiring layer. After defining the prohibited wiring layer, the wiring with electrical characteristics cannot exceed the boundary of the prohibited wiring layer in the subsequent wiring process.

8. Multilayer

Multi layer. The pads and through-hole on the circuit board need to penetrate the entire circuit board to establish electrical connections with different conductive graphic layers. Therefore, the system has set up an abstract layer - multilayer. Generally, pads and vias must be set on multiple layers. If this layer is closed, pads and vias cannot be displayed.