There are many factories on the market that can make PCBA fast proofing, but there are not many good factories that can guarantee both delivery time and quality. It is necessary for you to judge and choose by yourself. Next, KingFord will introduce how to choose a good PCBA fast proofing factory to avoid pits. Select the method of PCBA fast proofing factory. The following patch processing manufacturers Xiaobian to explain how to choose a good PCBA factory to avoid pits and circuit board production drilling how to choose the relevant knowledge of the plate.

How to select the board for PCB production drilling

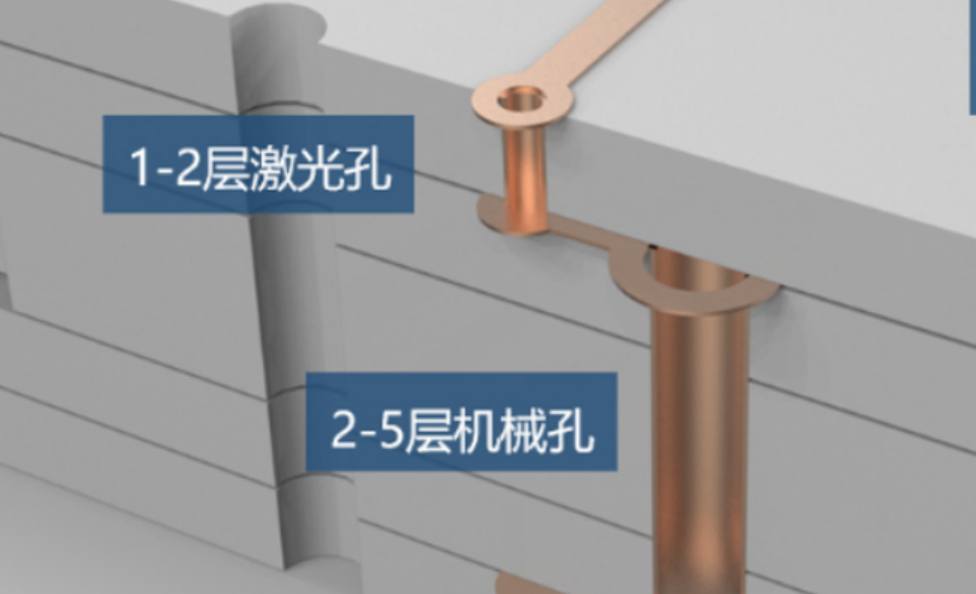

PCB drilling board requirements are: a certain surface hardness to prevent burr on the surface of the drilling. But not too hard to wear the drill. The resin composition of the upper and lower gasket plate itself should not be too high, otherwise the molten resin ball will be formed when drilling and adhered to the hole wall. The larger the thermal conductivity, the better, so that the heat generated during drilling can be quickly taken away, reducing the temperature of the drill when drilling, and preventing the annealing of the drill. The PCB board should be rigid to prevent vibration during drilling, and it should be elastic to deform immediately when the bit is in contact with the drill, so that the bit can be accurately aligned with the position to be drilled and ensure the accuracy of the drilling position. The material should be uniform without impurities producing uneven soft and hard nodes, otherwise it is easy to break the bit.

If the upper pad surface is hard and slippery, the small diameter drill bit may slip away from the original hole position and create elliptical diagonal holes in the PCB. The upper gasket plate used in China is mainly 0.2-0.5mm thick phenolic paper glue board epoxy glass cloth board and aluminum foil, such as LF2Y2 (No.2 rust resistant aluminum semi-cold hardening state or LF21Y (No. 21 rust resistant aluminum cold hardening state) of 0.3mm thickness as the upper gasket plate of common double panel drilling effect is better, to achieve suitable hardness can prevent burr on the surface of drilling. Because aluminum has good thermal conductivity, rigidity and elasticity, it has a certain heat dissipation effect on the drill bit. Compared with phenolic board, the aluminum foil material has no impurities and the probability of breaking the drill bit and deviation hole is much smaller than phenolic board.

It can reduce the temperature of drilling hole and is an environmentally friendly material, which is increasingly widely used in many factories. At the same time, compared with phenolic board and epoxy board, it will not pollute the hole by resin because of the resin it contains. 0.15, 0.20 and 0.30mm thickness of aluminum foil are commonly used. 0.15 has the best contact with PCB surface in actual use, but it is difficult to control the process in cutting, transportation and use. The price of 0.30 is a little higher, so 0.20mm aluminum foil is generally used as a compromise. The actual thickness is generally 0.18 mm. There is a composite plate, the upper and lower layers are 0.06mm aluminum alloy foil, the middle layer is a pure fiber core, the total thickness is 0.35mm. It is not difficult to see that this structure and material can meet the requirements of printed board drilling plate, used for high-quality multilayer plate plate, compared with aluminum foil, its advantages are: high drilling quality, high precision hole position, due to wear small drill life, at the same time PCB board external force after the return of the original shape is much better than aluminum foil, much lighter weight, especially suitable for drilling holes. The lower cushion board used in China has phenolic paper board, cardboard, wood chip board.

Cardboard is soft and easy to produce burrs, but the uniform texture is not easy to break the bit and bite the bit, but the price is cheap, can be used in thin copper foil or single panel. The wood chip board has poor texture uniformity and better hardness than paper board. However, if PCB copper foil drilled is larger than 35 microns, it will produce burrs. I have tried to drill dual panels of 70 micron copper foil with this board, but all the results failed. Phenolic paper board hardness is the best uniformity between the former two, the use of the best effect but more expensive and not environmentally friendly. There is also a composite bottom plate abroad, the upper and lower layers are 0.06mm aluminum alloy foil, the middle layer is a pure fiber core, the total thickness is 1.50mm. Of course, the performance is very outstanding and environmental protection, much more than phenolic paper board, especially when drilling multilayer board and small diameter holes can fully reflect its advantages, the disadvantage of course is expensive.

How to choose a PCBA factory to avoid pits

1, look at the professional PCBA processing factory, PCBA processing is different from the traditional SMT patch and DIP plug-in. In the past, the simple electronic processing, the customer provides the materials, the factory only needs to produce according to the requirements, but the PCBA processing is the material procurement, material quality inspection, warehouse management, SMT patch, DIP plug-in, quality inspection, The PCBA processing plant is required to have a certain degree of professionalism, including professional equipment, professional process system management and perfect quality control system.

2, look at the service consciousness of PCBA processing plant, the docking staff and the whole company team need to have a good sense of service, only in this way, when customers encounter problems, can take the initiative to take responsibility for solving problems.

3. PCBA processing plants with a lot of experience in rapid proofing only do batch orders, and do not have much interest in small quantity proofing orders. Even if such processing plants cooperate, they cannot cooperate 100%, which will only increase the annoyance and affect the efficiency of PCBA rapid proofing.

4, see whether can deliver on time when choosing PCBA express proofing factory, special attention should be paid to whether can keep the promise to complete the proofing work on time, quality and quantity, because of the particularity of fast proofing, often need to finish this thing in a certain time window, otherwise after this time, no matter how well done the product will have no market. So whether it can be delivered on time is also particularly important