Circuit board manufacturer explains double-sided soft board

Circuit board manufacturer, circuit board design and PCBA processing manufacturer explain to you: circuit board manufacturer explains double-sided soft board

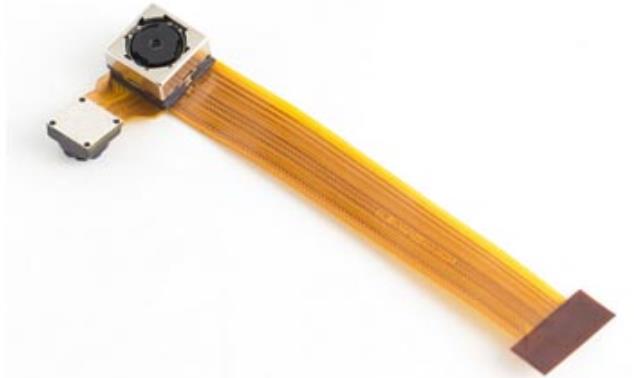

Flexible Printed Circuit Board (FPC) is referred to as "flexible Board", commonly known as FPC in the industry. It is a Flexible insulating substrate (mainly polyimide or polyester film) The printed circuit board has many advantages that the hard printed circuit board does not have. For example, it can bend, wind and fold freely. The volume of electronic products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras and other fields or products.

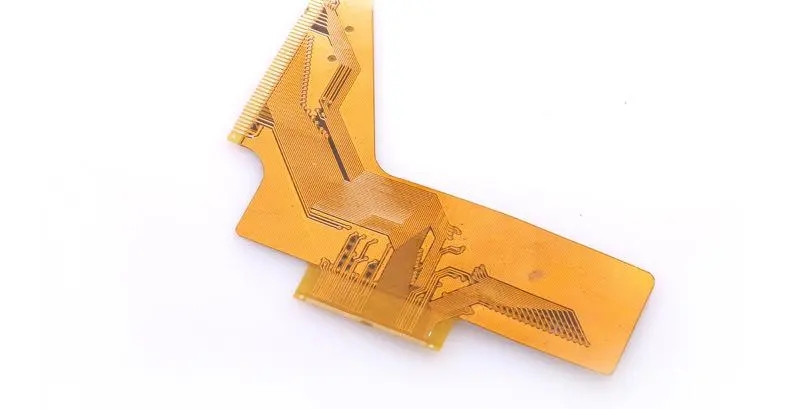

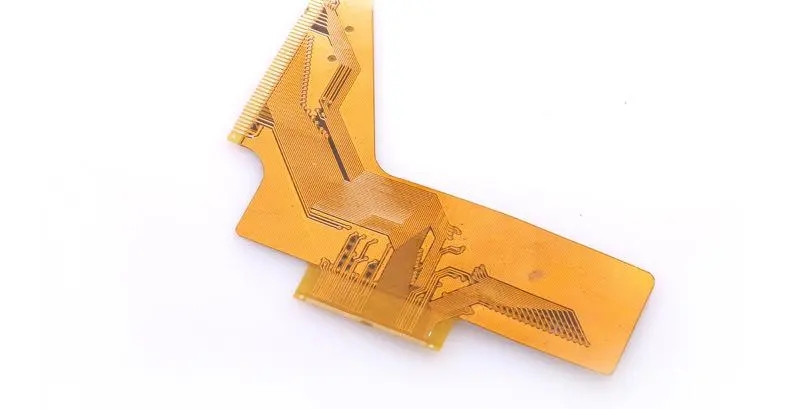

When FPC lines cannot be completed by single layer lines or there is a need for lines to cross lines, it becomes necessary to increase the number of conductor layers to increase the density of line connections to meet the design requirements. The double-sided board is a double-layer conductor, which is attached to the soft substrate with a batch of adhesives. The connection between the double-layer conductors can be connected between layers by means of electroplating through holes, solder hole filling bumps, etc.

The most common way to connect the layers of double-sided soft boards is the electroplating through hole method. The through hole is formed on the substrate first, which can be drilled mechanically or by laser, depending on the size of the hole diameter and the density of the lines, or it can be washed with a mold. The through hole is then completed by plasma etching or chemical etching; Hole wall cleaning and roughening treatment; Then metallization treatment is carried out on the surface of the hole. The electroless copper plating, conductive carbon film (blackening) or black shadow process can be used. After the completion of the electroplating process, the copper thickness will be increased to the required thickness, so that the connection between the double-layer conductors can be completed.

With the demand of high-density circuit, electroplated through-hole can be designed as full electroplating and partial electroplating. Overall electroplating will thicken the surface copper, which is unfavorable to the production capacity of thin lines. In dynamic applications, it is also easy to generate internal stress, which will make the copper foil fatigue and fracture; Some electroplating processes are only carried out at the through-hole, and the areas outside the through-hole are covered with shielding materials. In this way, the connection between the two conductor layers can be completed without affecting the thin line capability and the reliability of dynamic application.

The common interlayer connectivity technologies are also the covering type, conductive material hole filling type and polymer thick film technology hole filling type. The appropriate process can be selected according to the accuracy requirements and conductivity requirements. As long as the conductive layers can be interconnected, any method can be tried. However, considering the process stability, process applicability and economic scale, electroplating through hole is still the most widely used technology, and the popularity of other technologies is still low. Circuit board manufacturers, circuit board designers and PCBA manufacturers will explain to you: circuit board manufacturers will explain double-sided soft boards.