Harm of chloride ion to PCB substrate and its treatment

Generally, people only know that chlorine can kill bacteria, which is usually used in tap water and swimming pools. Chlorine bleach can also make our clothes white and bright, but daily life is different from electronic products. PCB manufacturers should pay attention to the following matters:

For PCBA plate processors, the presence of chloride ions will cause electric leakage, erosion and ionization of metal substances. Chlorine is a non-metallic substance with strong activity. If there are enough chloride ions on the module board, the ion electrode potential formed by the combination of chlorine and moisture in the moisture will cause corrosion and metal ionization.

There are many potential sources of chloride ions in printed circuit production. In general, it is difficult to find out all the sources of chloride ions. The places where this happens frequently include the flux in the hot air leveling (HASL), the sweat on the operator's skin, and the tap water for cleaning, etc.

The content of chloride ion is affected by the chemical composition of the flux. Due to the natural characteristics of rosin resin, if high-quality solid rosin is used as the flux (such as active flux or light active flux) in the assembly process, the content of chloride ions is relatively high. Resin based or rosin based water-soluble fluxes and non cleaning fluxes are the opposite in this respect. Therefore, the chloride ion content of water-soluble or non cleaning flux used for assembly welding process is low.

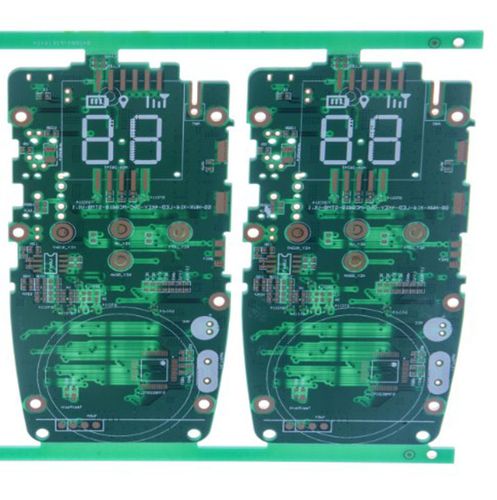

The content of chloride ion is affected by the material of PCB substrate. The material of PCB substrate (including its insulating substrate and attached metal) determines the allowable chloride ion content during assembly. Ceramic mixture substrate or other materials formed on refractory materials, such as aluminum, are more sensitive to the presence of chloride ions than organic substrates, such as epoxy glass cloth substrate. This is partly due to the fact that the surface integrated distribution has reached the micro scope. As far as the surface metal layer is concerned, the nickel/gold surface itself is much cleaner than the lead/tin surface.