Pcb factory: how to conduct aging test and environmental test on instruments and meters?

The circuit board manufacturer and circuit board designer will explain how to conduct aging test and environmental test on instruments and meters.

The instruments often used in industry will meet the requirements of product aging, aging test and environmental test after a certain period of use. It can detect a potential failure of early instruments, prepare solutions and solutions, especially common failures that can be found. Therefore, the same instruments and equipment can be recovered early by modifying circuits and methods, which is a tool to improve durability and reliability.

1. Aging test:

In general aging test, some instruments and meters shall be powered on for a long time, and their mean time between failures shall be measured. The fault characteristics of these instruments and meters shall be analyzed and summarized to find out their common problems and solve them.

2. Environmental test:

The specific test contents are generally determined according to the working environment of instruments and meters, and the test is carried out according to the methods specified by the state. The environmental test is generally carried out only for a small number of products, and the common environmental test contents and methods are as follows:

(1) Temperature test. Temperature test is used to check the impact of temperature environment on instruments and meters, and determine the adaptability of instruments and meters to work and store under high and low temperature conditions. It includes high and low temperature load test, high and low temperature storage test. High temperature test is used to check the impact of high temperature environment on instruments and meters, and determine the adaptability of instruments and meters to work and storage under high temperature conditions. It includes high temperature load test and high temperature storage test. Low temperature test is used to check the impact of low temperature environment on instruments and meters, and determine the adaptability of instruments and meters to work and storage under high temperature conditions. It includes low temperature load test and low temperature storage test. The temperature load test is to put the instruments and meters into the temperature test box for the test of the upper and lower limit of the rated working temperature when the samples are unpacked, without power and in the normal working position.

(2) Vibration and impact test. Vibration test to check the stability of instruments and meters under vibration. The method is to fix the sample on the vibration table and conduct the test by simulating various vibration environments such as fixed frequency (50HZ) and variable frequency (5-2KHZ). After a cycle is completed within a certain frequency range, the inspection shall be carried out as required. For example, the zirconia oxygen content analyzer must avoid vibration and shock. Experiments have proved that the gas analyzer cannot work because the zirconia tube inside the zirconia probe is vulnerable to vibration and damage.

Impact test is used to check the adaptability of instruments and meters to withstand non repeated mechanical impact. The method is to fix the sample on the test bench and impact the sample in different directions for several times with a certain acceleration and frequency. After the impact test, check whether the main technical indicators still meet the requirements and whether there is mechanical damage.

(3) Transportation test. Transportation test is to check the packaging, storage and transportation capacity of the instrument. The method sample can be fixed on the test bench or installed on the truck for operation. The specific method is in accordance with the relevant standards. The transportation test shall be conducted according to the main technical indicators and performance of the detector.

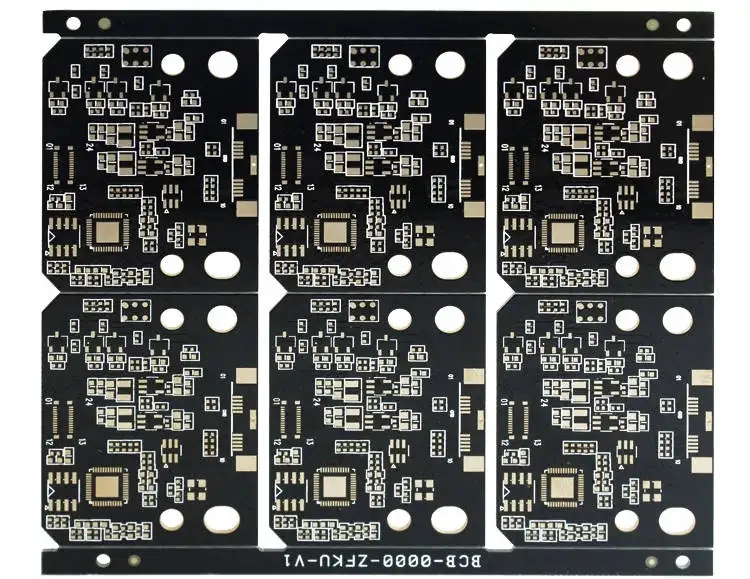

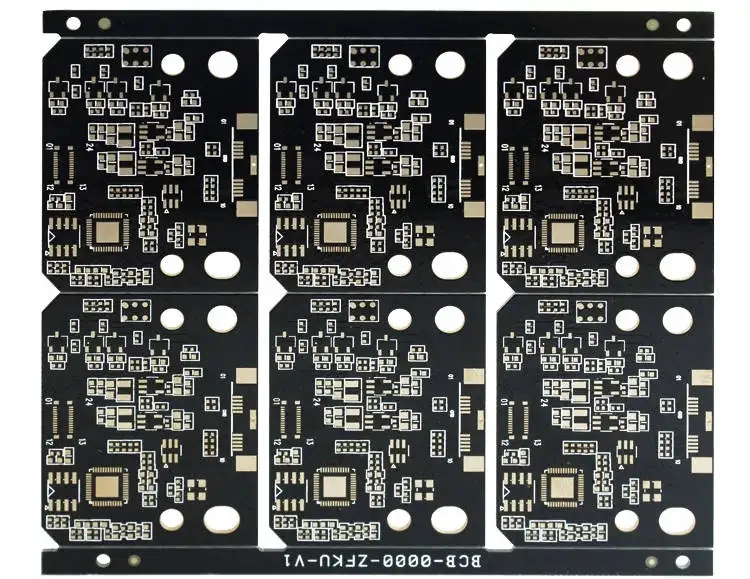

The aging test and environmental test are to check the reliability of the product. Generally, after PCBA processing, there will be aging test and environmental test.

The circuit board manufacturer and circuit board designer will explain how to conduct aging test and environmental test on instruments and meters.