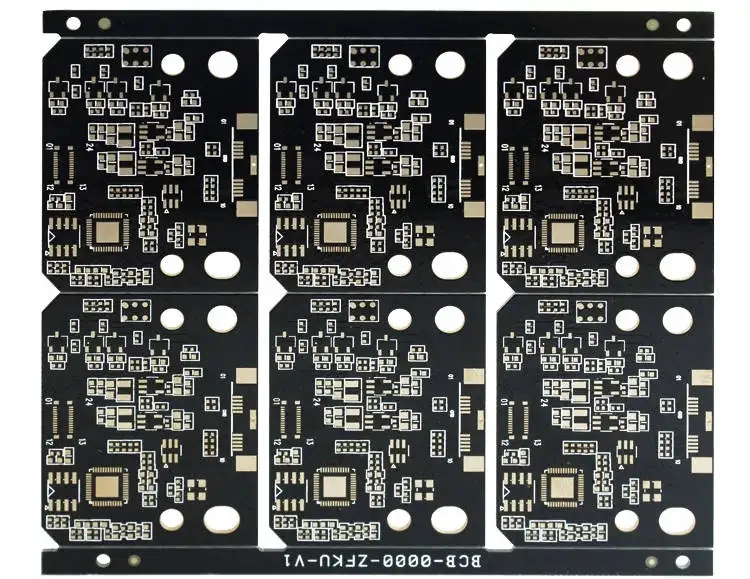

The following is an introduction to the methods and steps of copying PCB in the process of PCB board production:

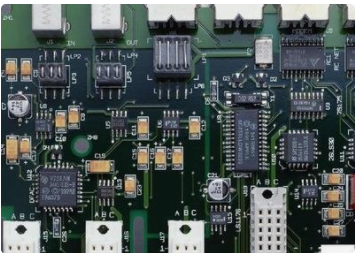

The first step is to get a PCB. First, record the models, parameters, and positions of all the elements on the paper, especially the directions of the diode, the three machine tube, and the IC notch. It is better to take two photos of the position of the pneumatic parts with a digital camera.

Step 2: Remove all PCB components and remove the tin in the PAD hole. Clean the PCB with alcohol, and then put it into the scanner. When the scanner scans, it needs to slightly raise some scanning pixels to get a clearer image. Start POHTOSHOP, scan the screen printing surface in color mode, save the file and print it for backup.

The third step is to slightly polish the TOP LAYER and BOTTOMLAYER layers with water gauze until the copper film is bright, put them into the scanner, start PHOTOSHOP, and scan the two PCB layers in color mode. Note that the PCB must be placed horizontally and vertically in the scanner, otherwise the scanned image cannot be used, and the file should be saved.

Step 4: Adjust the contrast and lightness of the canvas to make the part with copper film and the part without copper film have a strong contrast. Then turn the secondary image to black and white to check whether the lines are clear. If not, repeat this step. If the image is clear, save it as a black and white BMP file TOP.BMP and BOT.BMP. If you find a problem with the image, you can also use PHOTOSHOP to repair it.

Step 5: convert the two BMP files into PROTEL files, and call in two layers in PROTEL. If the positions of PAD and VIA passing through two layers basically coincide, the previous steps are well done. If there is any deviation, repeat the third step.

Sixth, convert BMP of TOP layer into TOP PCB, pay attention to convert to SILK layer, which is the yellow layer. Then you can trace lines on TOP layer, and place devices according to the drawing in step 2. Delete SILK layer after drawing.

Step 7: convert the BMP of BOT layer into BOT PCB, pay attention to convert it to SILK layer, which is the yellow layer, and then trace lines on BOT layer. Delete SILK layer after drawing.

Step 8: In PROTEL, call TOP.PCB and BOT.PCB, and combine them into a picture.

Step 9: Use a laser printer to print TOP LAYER and BOTTOM LAYER on the transparent film (1:1 ratio), put the film on that PCB, and compare whether there is any error. If yes, you will be done.

Others: If it is a multilayer PCB, you should carefully polish it to the inner layer, and repeat the third to ninth steps. Of course, the naming of figures is also different. It should be determined according to the number of layers. In general, it is much easier to copy double-sided boards than multilayer boards. Multilayer boards are prone to inaccurate alignment, so you should be particularly careful and careful when copying multilayer PCB (the internal through holes and non through holes are prone to problems).

This paper introduces the methods and steps of copying PCB in the process of PCB board production