Effective chassis grounding technology in PCB design

In electronic products, you will want PCB grounding to have the same type of stability. This is where good chassis grounding technologies come into play, as they prevent components from sitting on a soft, moving mattress like floor.

What is chassis grounding?

You will encounter various types of grounding in electronic equipment: signal grounding, power grounding, grounding, and in this case, chassis grounding. Each type of grounding is defined by where and how they are placed, and they act as a return path for the current flowing through the electronic device.

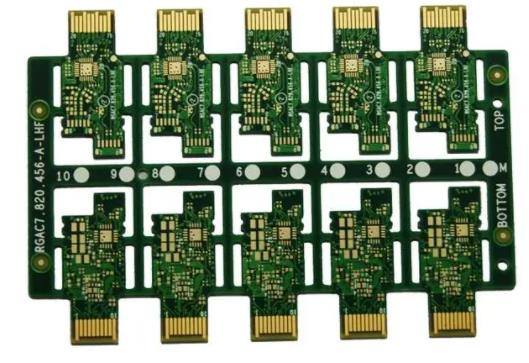

Some electronic devices are mounted in metal enclosures. Chassis grounding refers to the grounding connection connecting all metal parts to the ground. Several examples of chassis grounding are the metal shell of the oven (if it is safely grounded) and the metal body of the vehicle.PCB design and PCB assembly factory explain the effective chassis grounding technology, chassis grounding and chassis grounding in PCB design.

Why is chassis grounding important?

In theory, grounding is an electrical neutral point. In fact, the ground will never be at the theoretical "zero" voltage. Like signal wiring, ground planes also have impedance, and when measured, they will be at a lower voltage level.

Although non-zero voltages to ground rarely cause faults, chassis grounding is still important because the ground plane is vulnerable to transient events that can cause a sudden surge in current. A safe passage is required to allow excess current to flow, otherwise the components will be damaged. Chassis grounding is a safe and effective way to transfer excessive current.

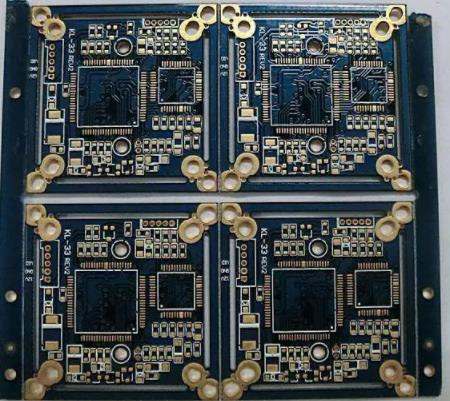

The ground is depicted as a stable reference plane for electronic signals, but in fact, it is nothing. All signals require a return path, and the ground plane is one of them. The signal ground plane, which is the return path of digital signal, is very noisy. Chassis grounding is an important part of grounding separation strategy to reduce ground noise. It provides a dedicated return path for the ground current. The PCB processing factory explains the effective chassis grounding technology, chassis grounding and chassis grounding in PCB design.

The chassis grounding not only helps to protect the PCB from surges and ground noise, but also acts as a shielding layer for EMI. The grounded enclosed case can be an effective Faraday cage, which can protect the PCB from external interference.

Application of chassis grounding technology

Chassis grounding can be tricky. If you do not do well, you will replace one question with another. Here are some strategies to remember:

1. Use single point grounding.

The grounding loop can be easily introduced when connecting to the chassis grounding. The grounding circuit may be the interference source of current flow and electromagnetic field. Therefore, it is important to ensure that only one ground connection is established between signal ground and chassis ground.

On the PCB, ensure that both analog and digital grounds are connected to a single point. The signal grounding shall also be connected to the chassis grounding through a single point. Generally, the mounting hole on the PCB is designated as chassis grounding, which should be connected as follows:

2. Connect the chassis to the ground

Even if the chassis is designated as chassis grounding, it should not be suspended. If possible, ground the chassis so that excess current can be safely transmitted to ground. Since the transient current will flow to the ground, this also prevents external noise from affecting the circuit.

These chassis grounding strategies will help you reduce noise on the PCB design and protect the design from current surges and EMI interference.